Cold-process inorganic phosphate precoated sand and preparation method thereof

A technology of inorganic phosphate and coated sand, applied in the direction of molding machines, manufacturing tools, casting molding equipment, etc., can solve the problems of toxic gas, high energy consumption of resin, secondary pollution, etc., to save costs and improve resistance to moisture absorption The effect of simplification and molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

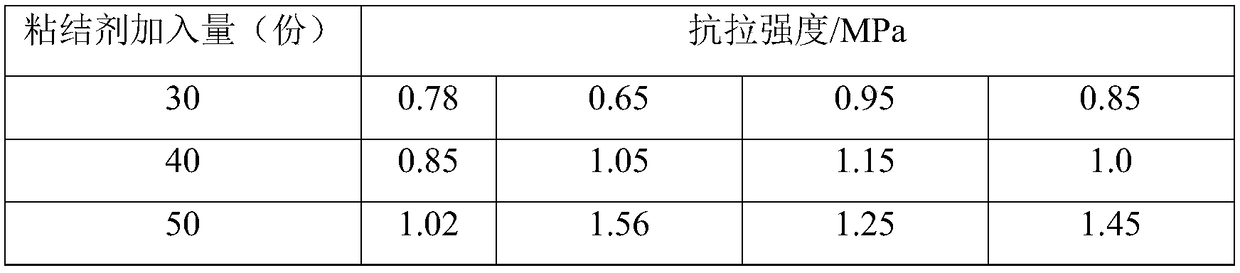

Embodiment 1

[0025] 1. Weigh 950g of raw sand, 30g of inorganic phosphate binder, and set aside;

[0026] 2. Add raw sand and inorganic phosphate binder into the mixer and stir for 120 seconds;

[0027] 3. Add 2 parts of magnesia powder and continue stirring for 30 seconds;

[0028] 4. The mixer continues to stir, and the liquid nitrogen is continuously fed into the mixer, so that the wet coated sand is frozen and solidified in the low temperature environment of liquid nitrogen, and the amount of liquid nitrogen added is 0.5L (405g);

[0029] 5. Break the large solid coated sand with a mixer;

[0030] 6. The crushed coated sand is screened to obtain granular coated sand;

[0031] 7. Inject granular coated sand into the mold through a core shooter (mold temperature 140°C, sand injection pressure 4MPa);

[0032] After 8.4 minutes, open the mold and eject the sand sample.

Embodiment example 2

[0034] 1. Weigh 960g of raw sand, 40g of inorganic phosphate binder, and set aside;

[0035] 2. Add raw sand and inorganic phosphate binder into the mixer and stir for 120 seconds;

[0036] 3. Add 3 parts of magnesia powder and continue stirring for 30 seconds;

[0037] 4. The mixer continues to stir, and liquid nitrogen is continuously added to the mixer, so that the wet coated sand is frozen and solidified under the low temperature environment of liquid nitrogen, and the amount of liquid nitrogen added is 1L (810g);

[0038] 5. Break the large solid coated sand with a mixer;

[0039] 6. The crushed coated sand is screened to obtain granular coated sand;

[0040] 7. Inject the sieved sand into the mold through a core shooter (mold temperature 145°C, sand injection pressure 4MPa);

[0041] After 8.4 minutes, open the mold and eject the sand mold.

Embodiment example 3

[0043] 1. Weigh 980g of raw sand and 50g of inorganic phosphate binder, set aside;

[0044] 2. Add raw sand and inorganic phosphate binder into the mixer and stir for 120S;

[0045] 3. Add 5 parts of magnesia powder and continue to stir for 30 seconds;

[0046] 4. The mixer continues to stir, and liquid nitrogen is continuously added to the mixer, so that the wet coated sand is frozen and solidified under the low temperature environment of liquid nitrogen, and the amount of liquid nitrogen added is 2L (1620g);

[0047] 5. Break the large solid coated sand with a mixer;

[0048] 6. The crushed coated sand is screened to obtain granular coated sand;

[0049] 7. Inject the sieved sand into the mold through a core shooter (mold temperature 150°C, sand injection pressure 4MPa);

[0050] 8. After 4 minutes, open the mold and eject the sand mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com