Stainless steel intelligent sorting machine and control method

A control method, stainless steel technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

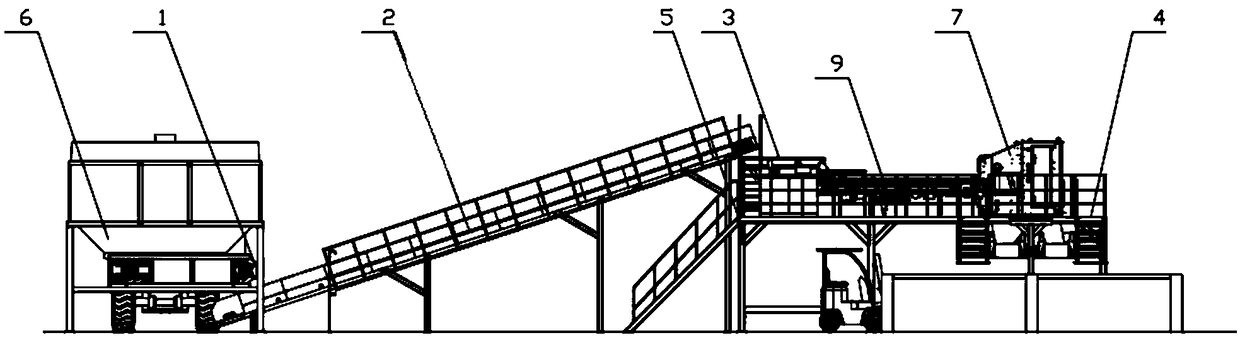

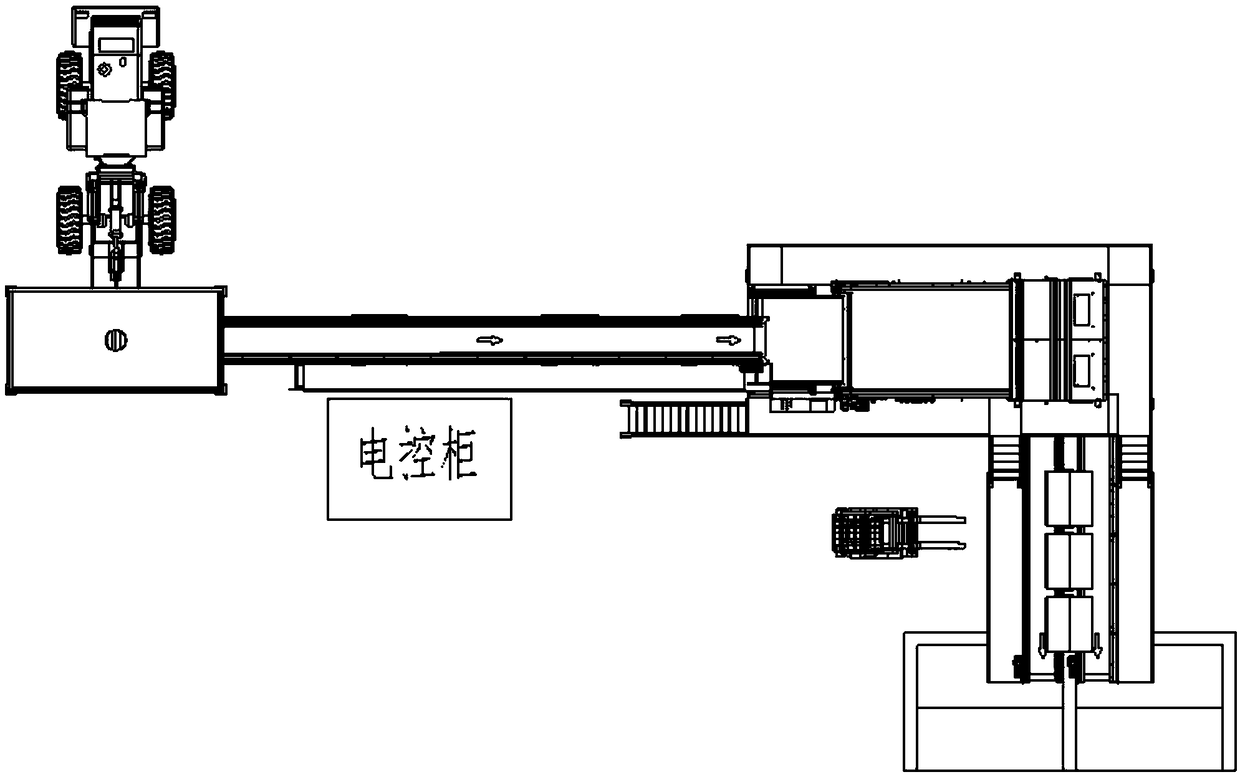

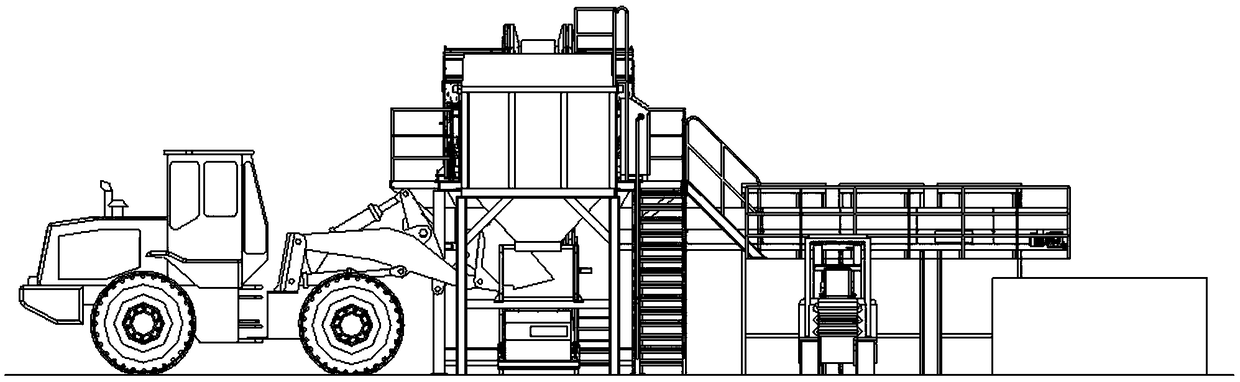

[0087] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0088] The control method of the stainless steel intelligent sorting machine provided by the embodiment of the present invention includes:

[0089] The tailings of the non-ferrous sorting line are transferred to the non-ferrous metal sorting area, fed to the scraper conveyor, the material is uniformly output through the scraper conveyor, and enters the vibrating conveyor through the belt conveyor, and the material is evenly dispersed to obtain scattered broken materials , The material enters the stainless steel induction sorter after passing through the vibrating conveyor, and the stainless steel material and non-stainless steel material are obtained through the sorting of the induction sorter, and are transported to the silo through two belt conveyors respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com