Granulating machine for sludge drying

A technology of sludge drying and granulator, which is applied in the direction of temperature control sludge treatment, dewatering/drying/concentrating sludge treatment, mold extrusion granulation, etc., which can solve the problem of poor cleaning ability and sludge inability to quickly Problems such as drying and granulation are not meticulous enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

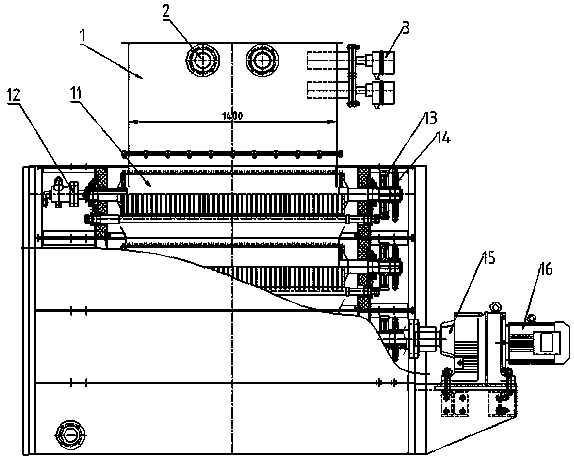

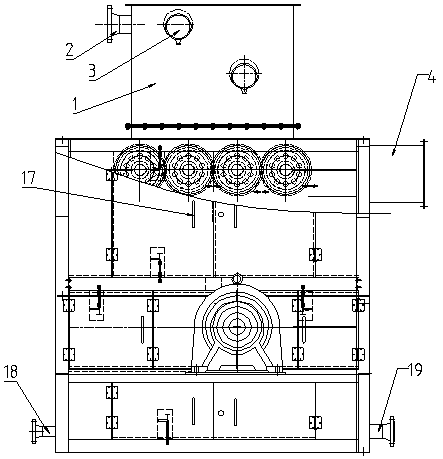

[0021] A granulator for sludge drying, including a body, the body includes a feeding device arranged on the top of the body and a granulation device arranged below the feeding device, the feeding device includes a buffer silo 1, a buffer silo Two feed nozzles 2 are provided on the front side of the upper part of 1, and two level devices 3 are provided on one side of the buffer storage bin 1.

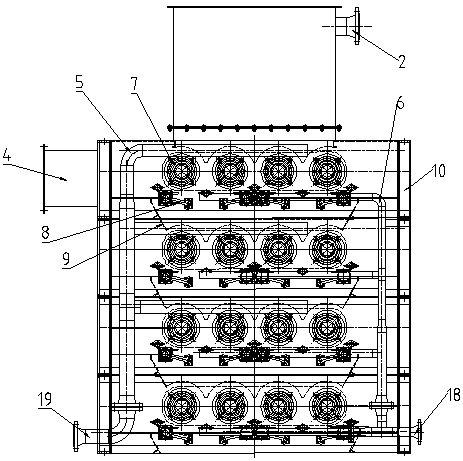

[0022] The granulation device includes a housing 10 and several granulation rollers 11 arranged inside the housing 10. The granulation rollers 11 are arranged in four rows, and each row is provided with four. Multiple granulation rollers 11 granulate at the same time, and the speed Fast, high efficiency, one side of the granulation roller 11 is provided with a rotary joint 12, the other side of the granulation roller 11 is provided with a gear 13, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com