TDS water quality detection filter

A water quality detection and filter technology, which is applied in the field of water treatment, can solve problems such as pollution and affecting the detection accuracy of the detection pen, and achieve the effects of reducing distance, improving assembly convenience, and stabilizing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

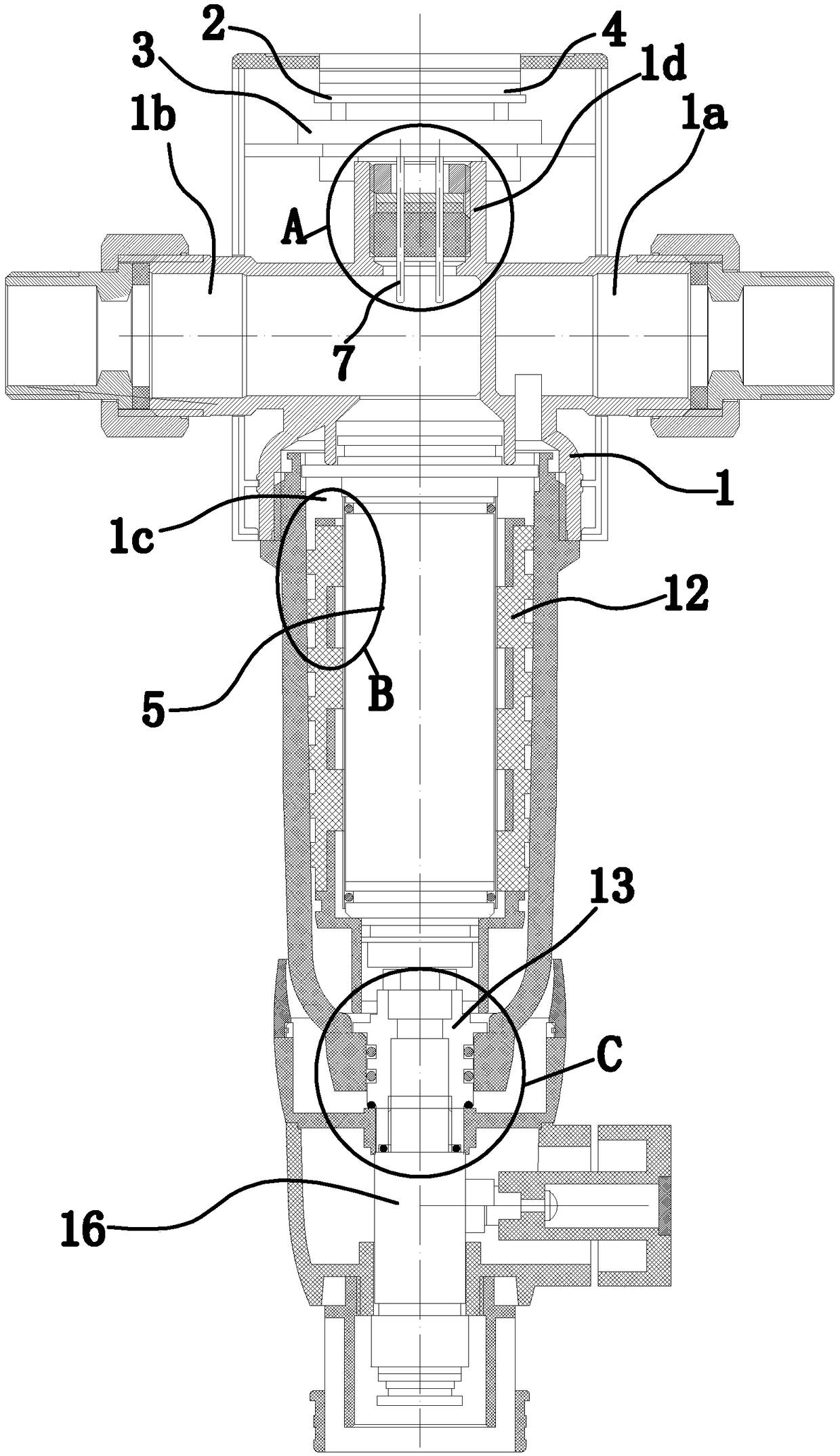

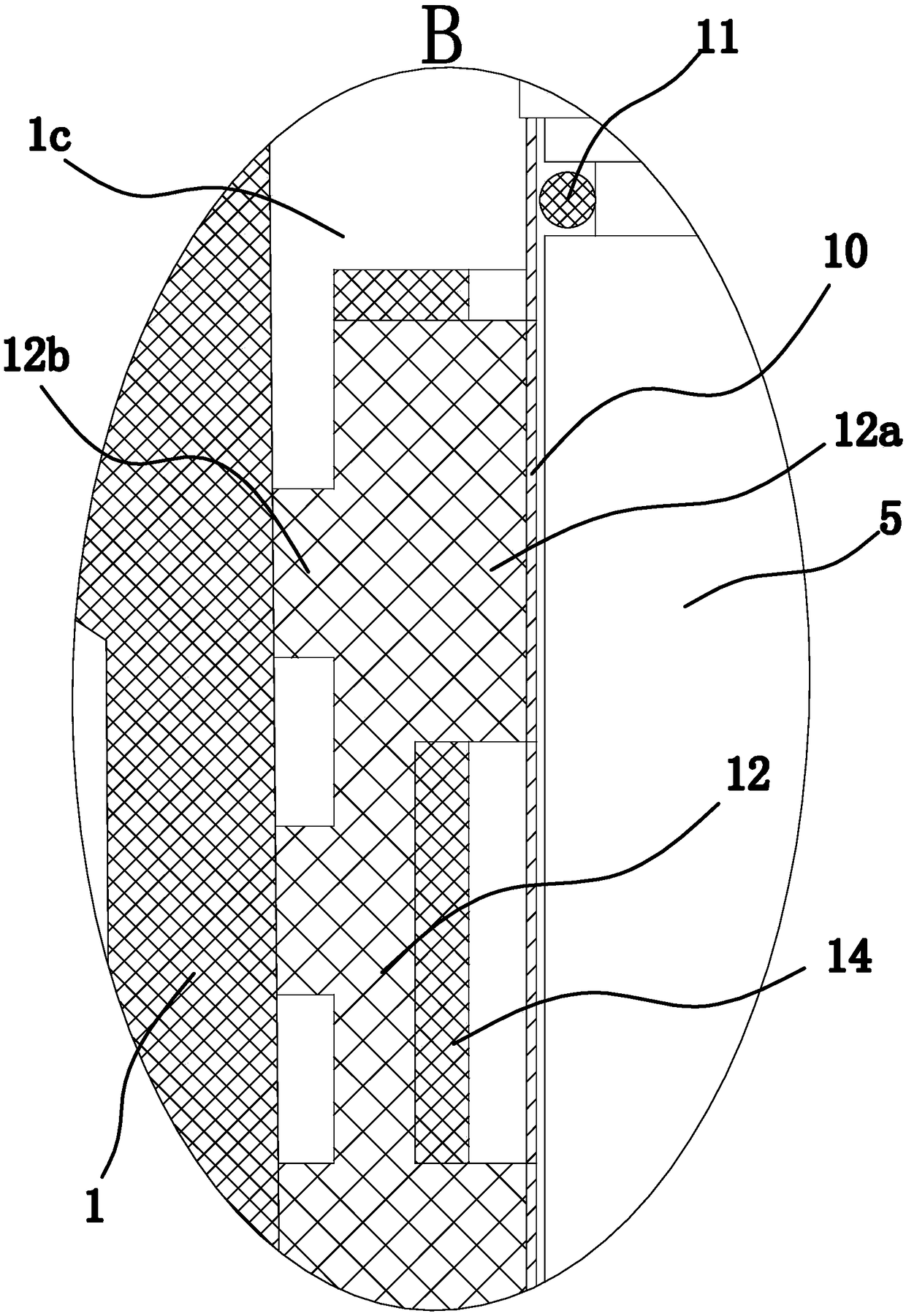

[0028] like figure 1 As shown, the TDS water quality detection filter includes a housing 1, and a circuit board 2, a battery 3 for powering the circuit board 2, and a liquid crystal component 4 installed on the circuit board 2 are arranged outside the housing 1.

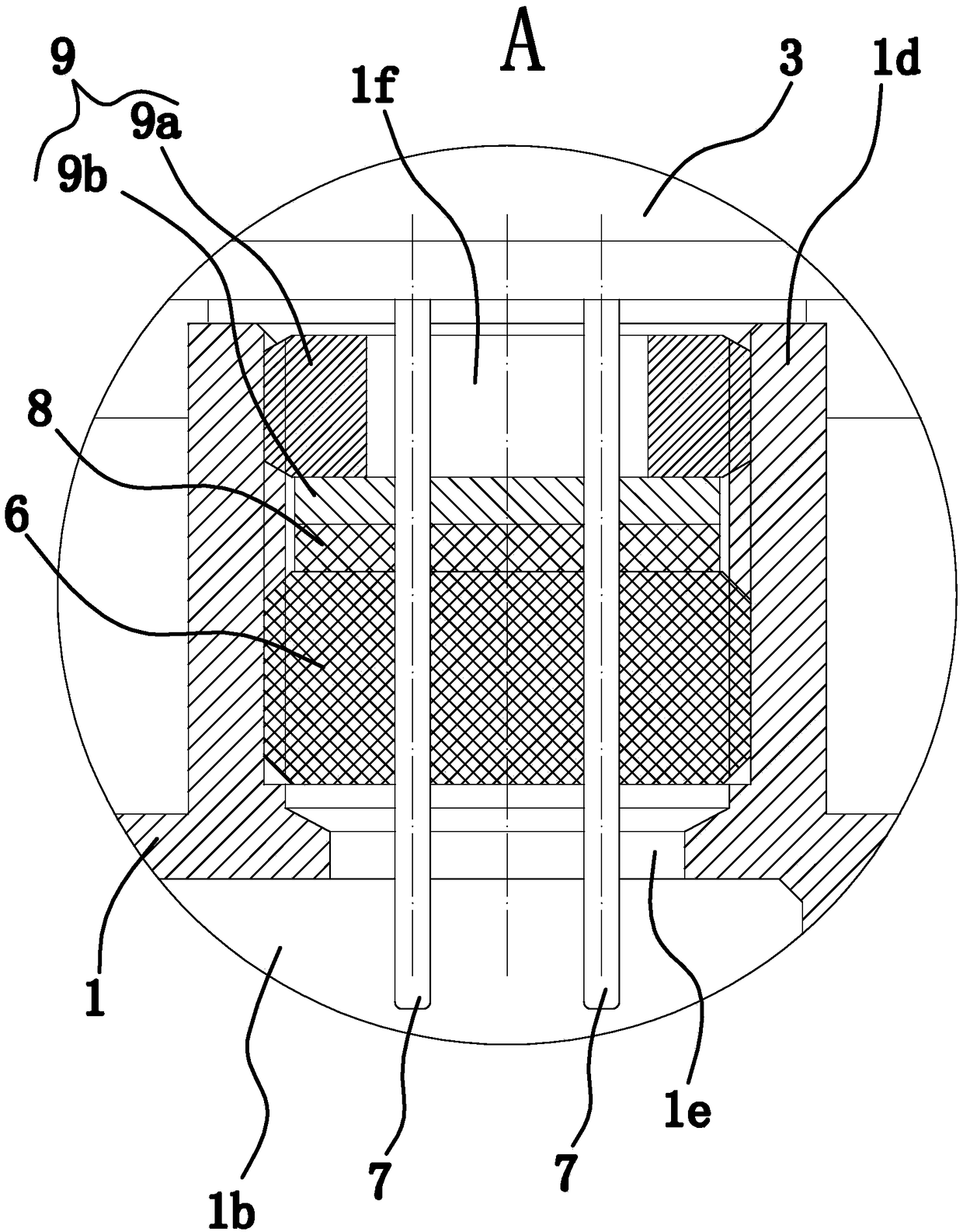

[0029] Specifically, the shell 1 has a water inlet channel 1a, a drain channel 1b, and a water passage chamber 1c for connecting the water inlet channel 1a and the drain channel 1b. Wherein, the water inlet channel 1a and the drainage channel 1b are arranged along the horizontal direction, and both the water inlet channel 1a and the drainage channel 1b are above the water passage chamber 1c. like figure 1 As shown, a filter element 5 is vertically provided in the water chamber 1c, and the filter element 5 includes a water outlet hole and a water inlet hole, and the water inlet hole and the water outlet hole communicate with the water chamber 1c and the drainage channel 1b respectively. In this embodiment, the filte...

Embodiment 2

[0039] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the driving mechanism includes an electric push rod, and the main shaft of the electric push rod is fixedly connected with the cleaning cylinder 12 through a connecting frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com