Preparation method of spirally sliced dried persimmon with through hole at center

A through-hole and slicing technology, which is applied in the field of preparation of spiral sliced persimmons, can solve the problems of high-quality dried persimmons such as wrinkling on the outside, inability to process milled persimmons, and collapsed products, so as to eliminate the worries of factors that induce constipation and improve the advantages of commercialization , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

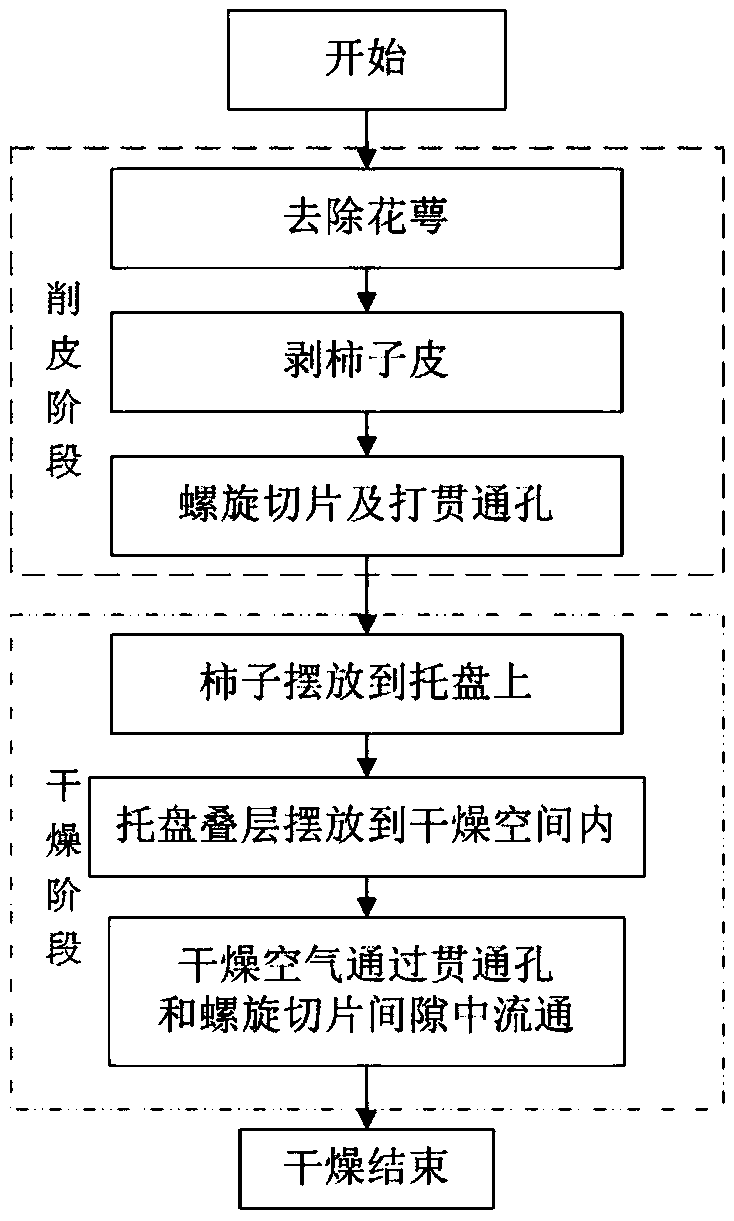

[0039] This embodiment provides a method for preparing a helically sliced persimmon with a through hole in the center. Usually, the average weight of the Mopan persimmon is about 250g. This embodiment is to illustrate that the method of the present invention can also be processed into high-quality persimmons that are larger in size. Dried persimmons, adopting the big Mopan persimmon (300g) that is higher than the average weight and more difficult to handle is that raw material is processed into dried persimmons, and the method is carried out according to the following steps:

[0040] Step 1: removing the calyx from freshly ground persimmons weighing 300 g and then peeling them to obtain pretreated persimmons;

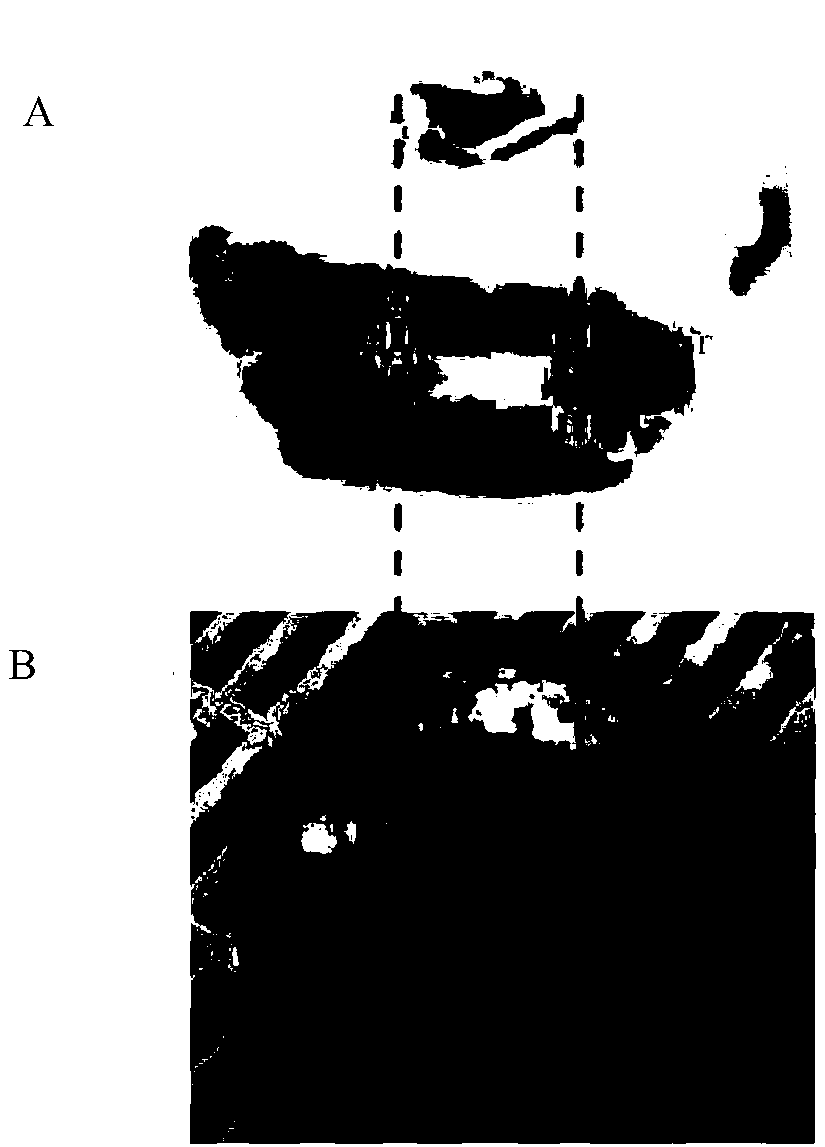

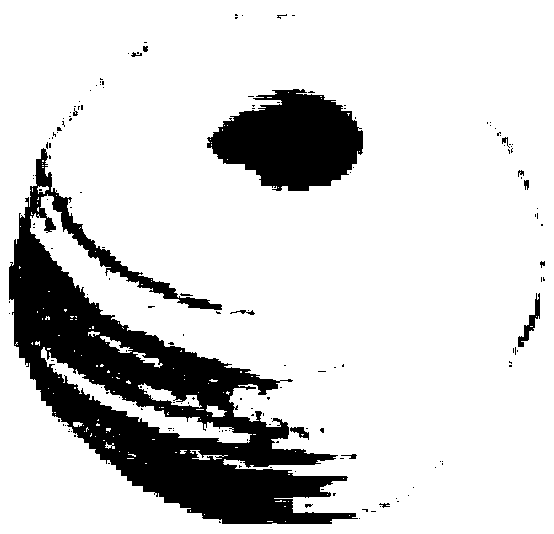

[0041] Step 2: Make a through hole through the upper surface and the lower surface of the persimmon in the center of the pretreated persimmon obtained in step 1 (the part of the through hole is discarded as the white fibrous persimmon core), and the persimmon is treate...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 lies in that the slice thickness of the helical slice is 40 mm, and the diameter of the through hole is 10 mm.

[0046] In this embodiment, the persimmons are dried until the moisture content is 30%, and the required drying time is 9 days. The obtained persimmons have no astringent feeling, less wrinkled appearance, slightly harder skin hardness than that of Example 1, and good taste.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 lies in that the slice thickness of the spiral slice is 15 mm, and the diameter of the through hole is 30 mm.

[0049] In this embodiment, the water content of persimmons is dried to 30%, and the required drying time is 4.5 days. The obtained persimmons have no astringent feeling, less wrinkles in appearance, and the hardness of the outer skin is slightly harder than that of Example 1, and slightly harder than that of Example 2. The skin hardness is slightly soft, and the taste is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com