A processing device for a flexible circuit board

A technology for flexible circuit boards and production equipment, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., and can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

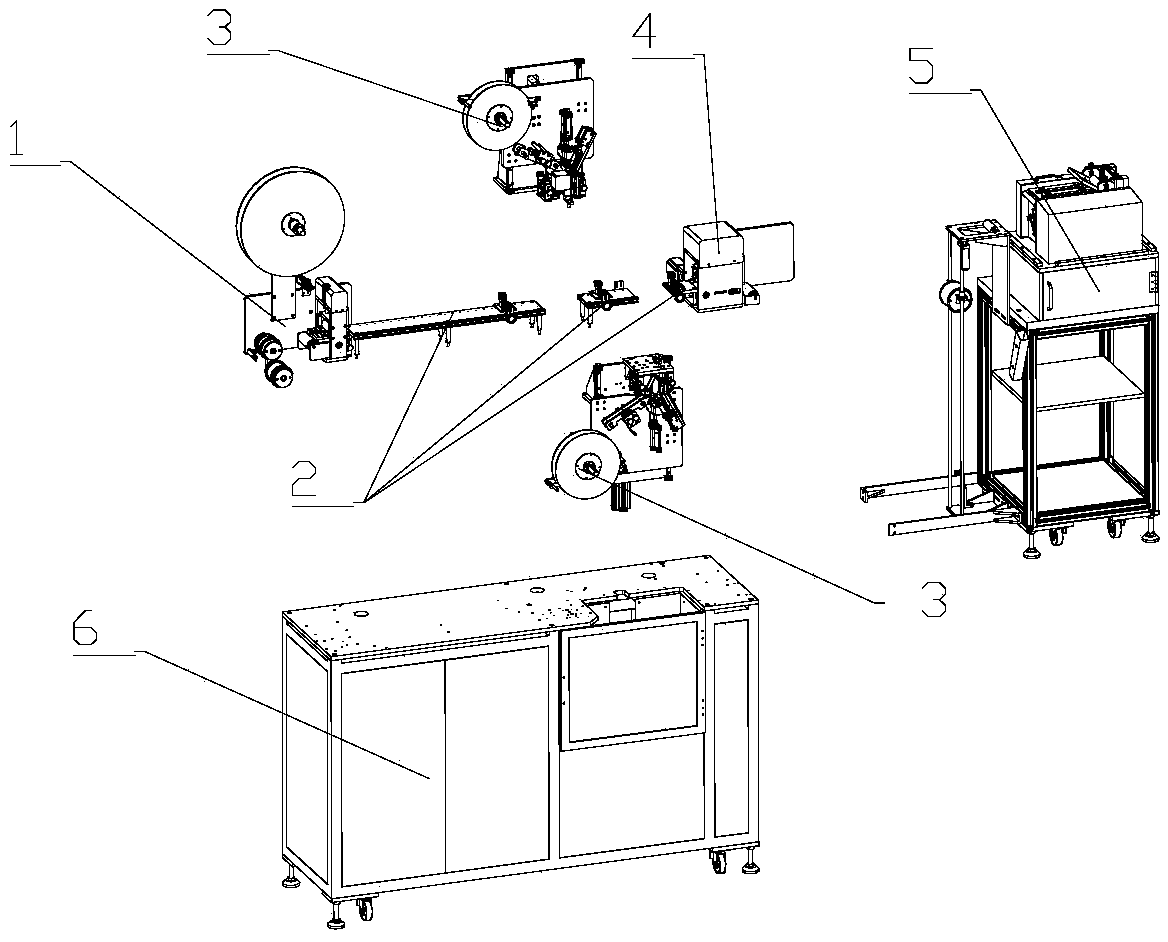

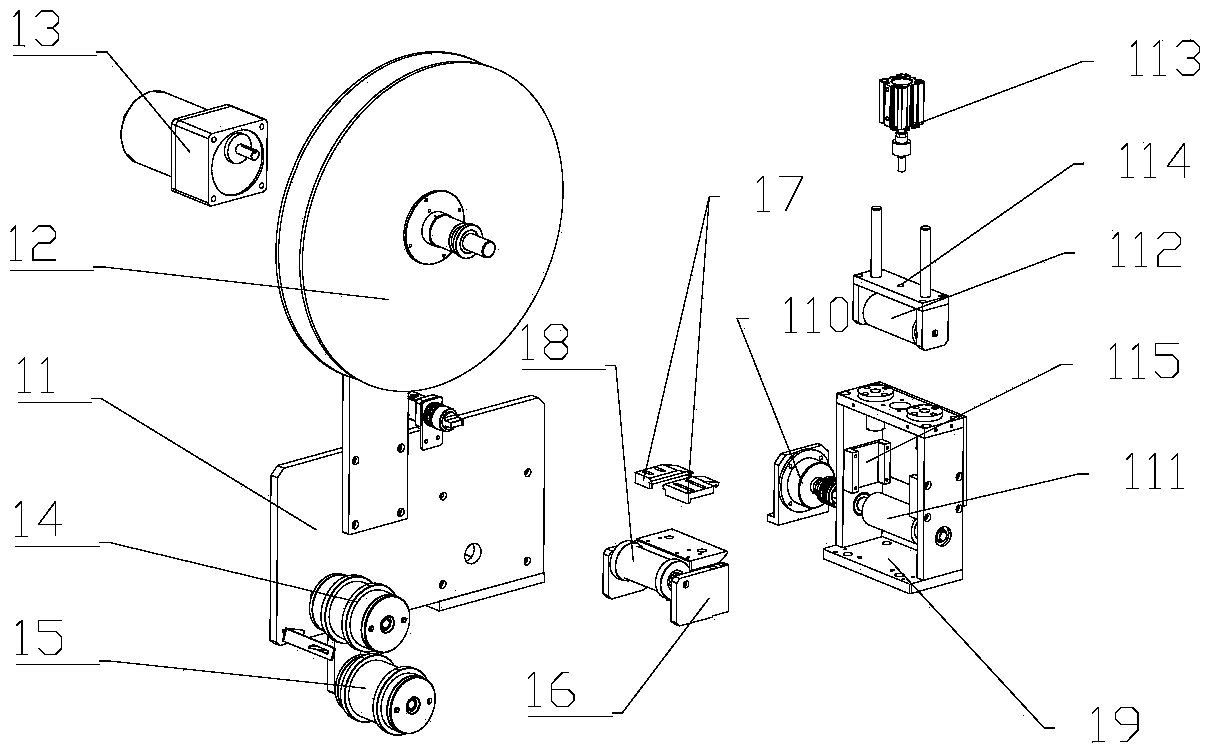

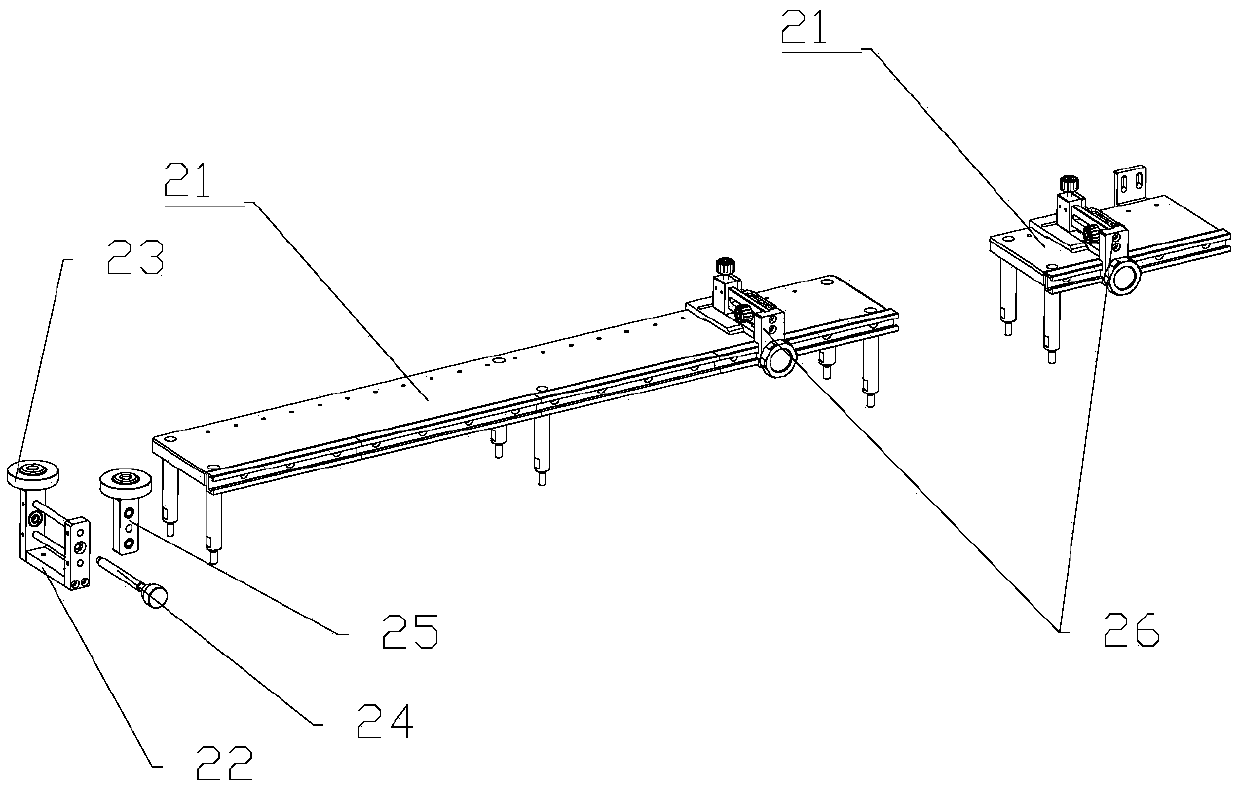

[0038] Combine below Figure 1-Figure 22 The present invention is further described.

[0039] Such as Figure 1-Figure 22 The shown processing equipment of a flexible circuit board includes a frame 6, a feeding device 1, a material passing platform assembly 2, a gluing device 3, a gluing device 4 and a cutting device 5, a feeding device 1, a material passing platform Component 2, gluing device 3 and gluing device 4 are installed on the frame 6, the feeding device 1 is connected with the material passing platform component 2, the position of gluing device 4 corresponds to the material passing platform component 2, gluing device 3, gluing The device 4 and the cutting device 5 are successively connected.

[0040] The material passing platform assembly 2 is used to guide the wire into a straight line and realize glue application there; there are two glue application devices 3 arranged up and down for pasting the upper and lower tapes; The glued paper is compacted on the wire; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com