Electrical outlet device, motor and electrical appliance

A technology for electrical appliances and outlet boxes, applied in the directions of electromechanical devices, electrical components, electric components, etc., can solve the problems of dislocation of the sealing gasket outlet box, affecting the sealing effect, retention, etc., to avoid excessive extrusion, avoid insufficient extrusion, Squeeze evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

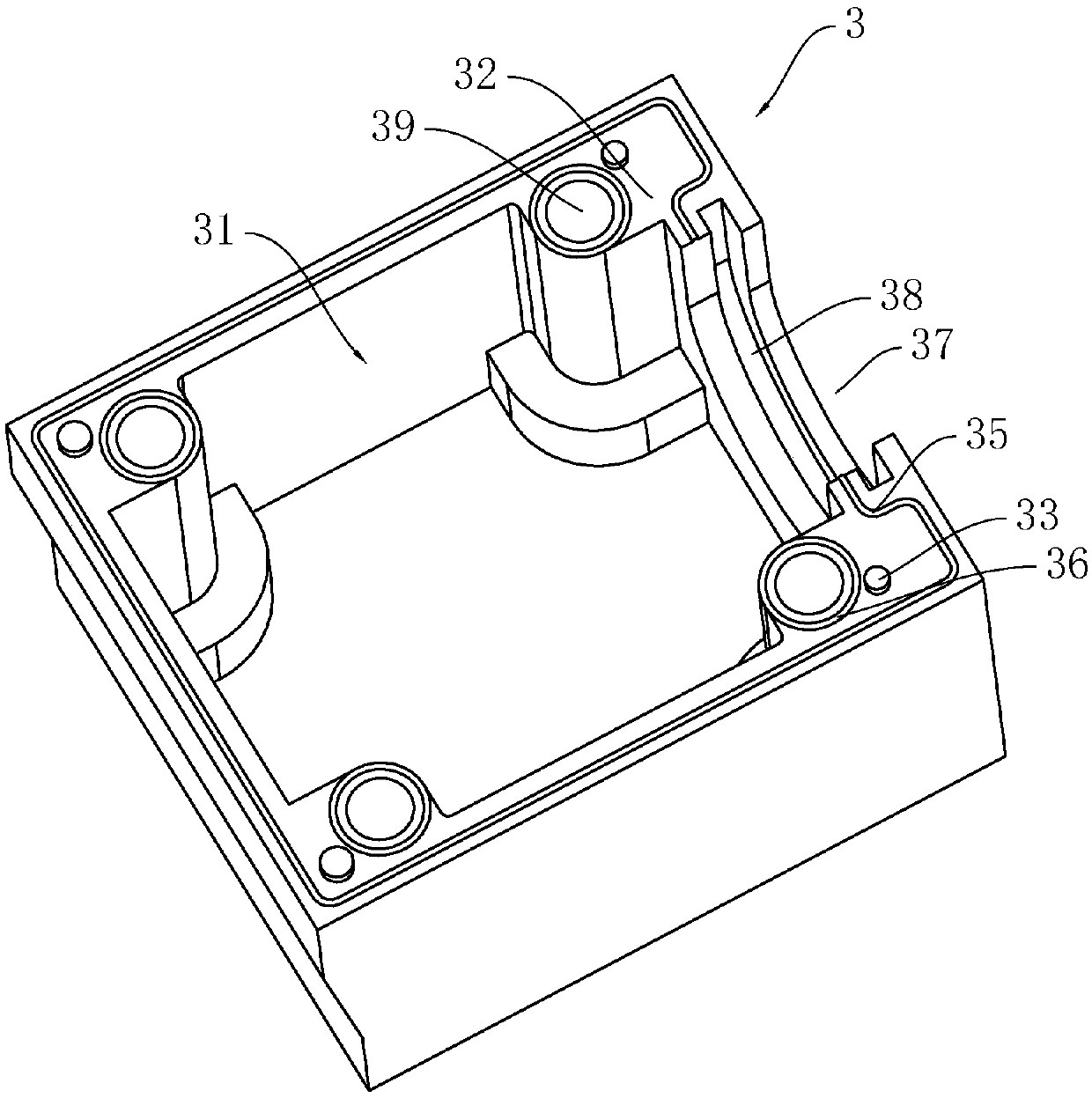

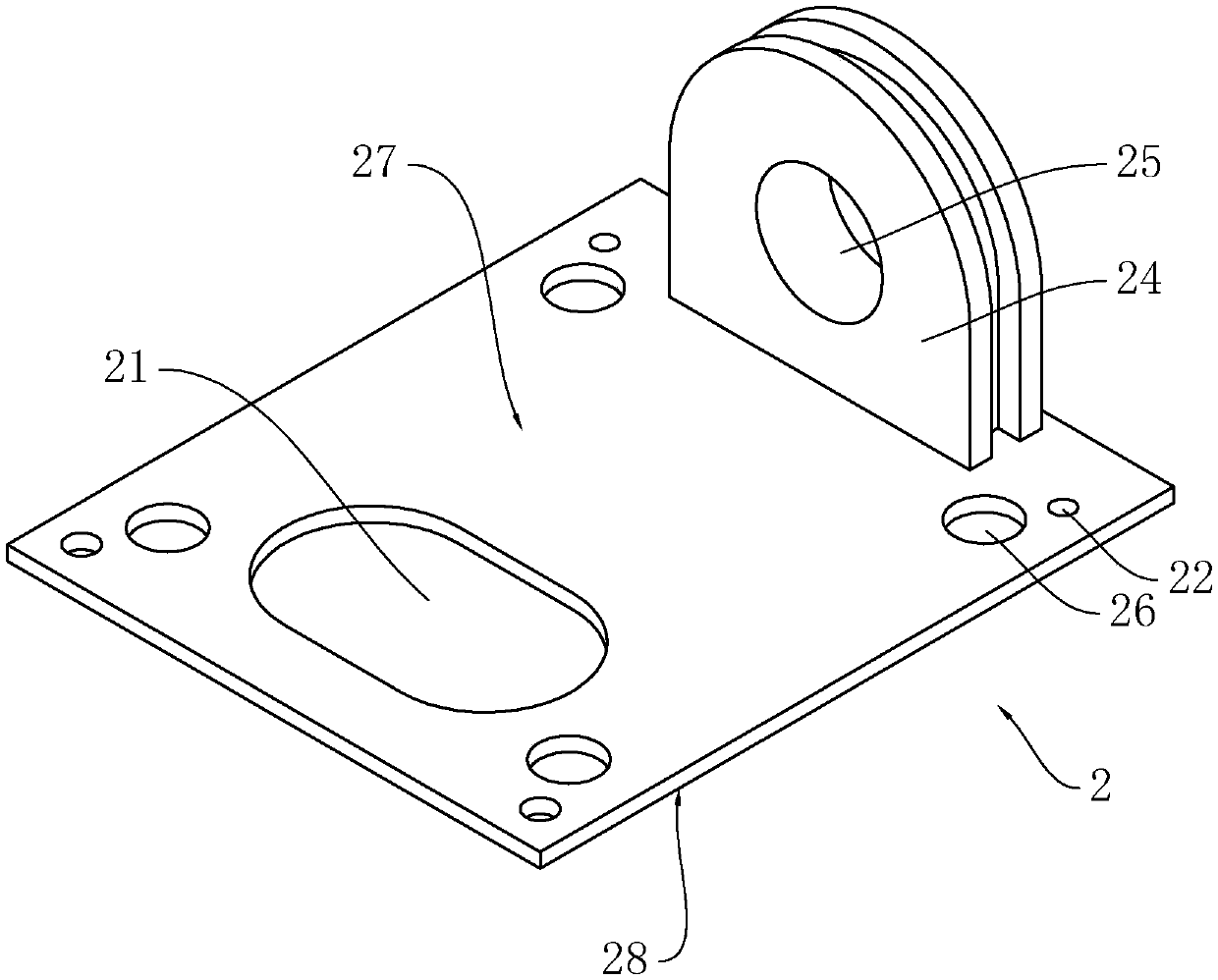

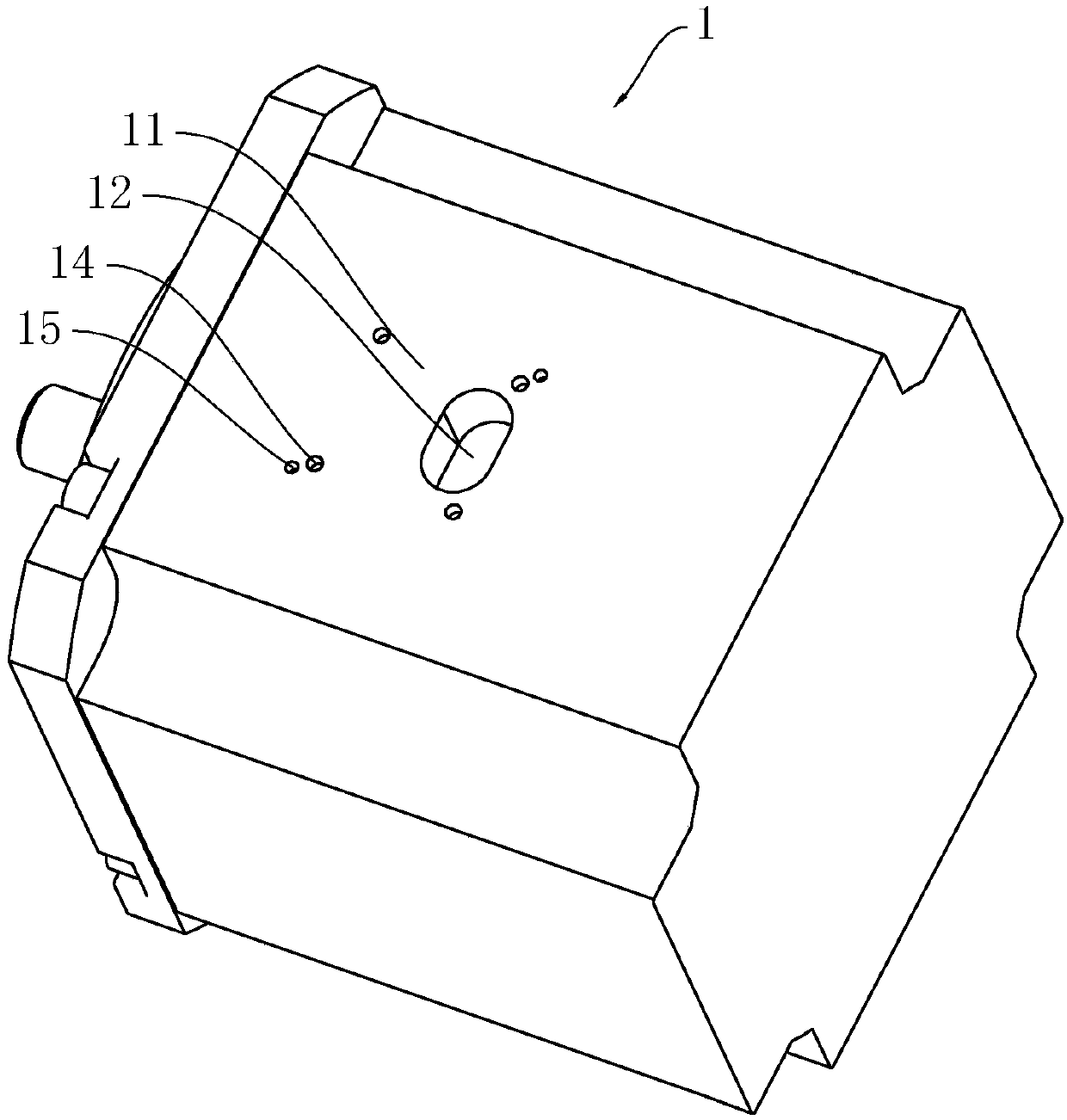

[0044] Please refer to Figure 1 to Figure 5 , the electrical outlet device of this embodiment has an electrical appliance housing 1, a gasket 2, an outlet box structure 3 and four screws 4; the electrical appliance housing 1 includes a first mounting surface 11, and the first mounting surface 11 is provided with a first outlet 12. The sealing pad 2 is provided with wiring holes 21 and four limiting holes 22 arranged in a dispersed manner. Seen from the direction perpendicular to the main surfaces 27 and 28 of the sealing pad 2, the cross-sectional shape of the sealing pad 2 is a quadrilateral. Two limit holes 22 are respectively located on the four corners of the gasket 2; the outlet box structure 3 includes a wire inlet 31 and a second installation surface 32, the outer contour of the second installation surface 32 is a quadrangle matching the gasket 2, and the inlet The line port 31 is arranged on the second installation surface 32; the four corners of the second installati...

Embodiment 2

[0063] Please refer to Figure 6 to Figure 10 , in the present embodiment, there are two positioning protrusions 34 scattered on the second mounting surface 32, and the height value of each positioning protrusion 34 is greater than the height value of any limiting protrusion 33; Two first positioning holes 23 are provided; two second positioning holes 13 are provided on the first mounting surface 11; each positioning protrusion 34 runs through each first positioning hole 23 one by one, and each positioning protrusion 34 one by one Correspondingly inserted into each second positioning hole 13 . In the process of installing the outlet box structure 3 to the electrical appliance housing 1, the outlet box structure 3 and the gasket 2 need to be installed in the specified position of the electrical appliance housing 1, by setting two positioning protrusions 34 on the second mounting surface 32 , two second positioning holes 13 are set on the first installation surface 11, and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com