Capacitor insulation cover produced from waste electrical polypropylene film

A polypropylene film and capacitor technology, used in capacitors, electrical components and other directions, can solve the problems of capacitor discharge, safety performance degradation, cracked wire skin, etc., to maintain stable separation distance, prevent creepage distance from shortening, and increase safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

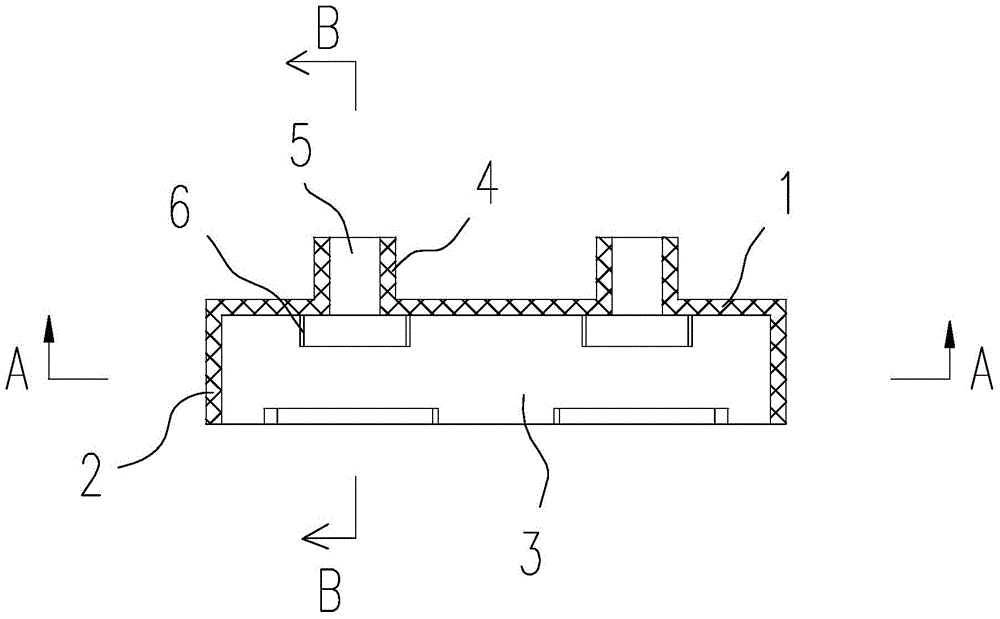

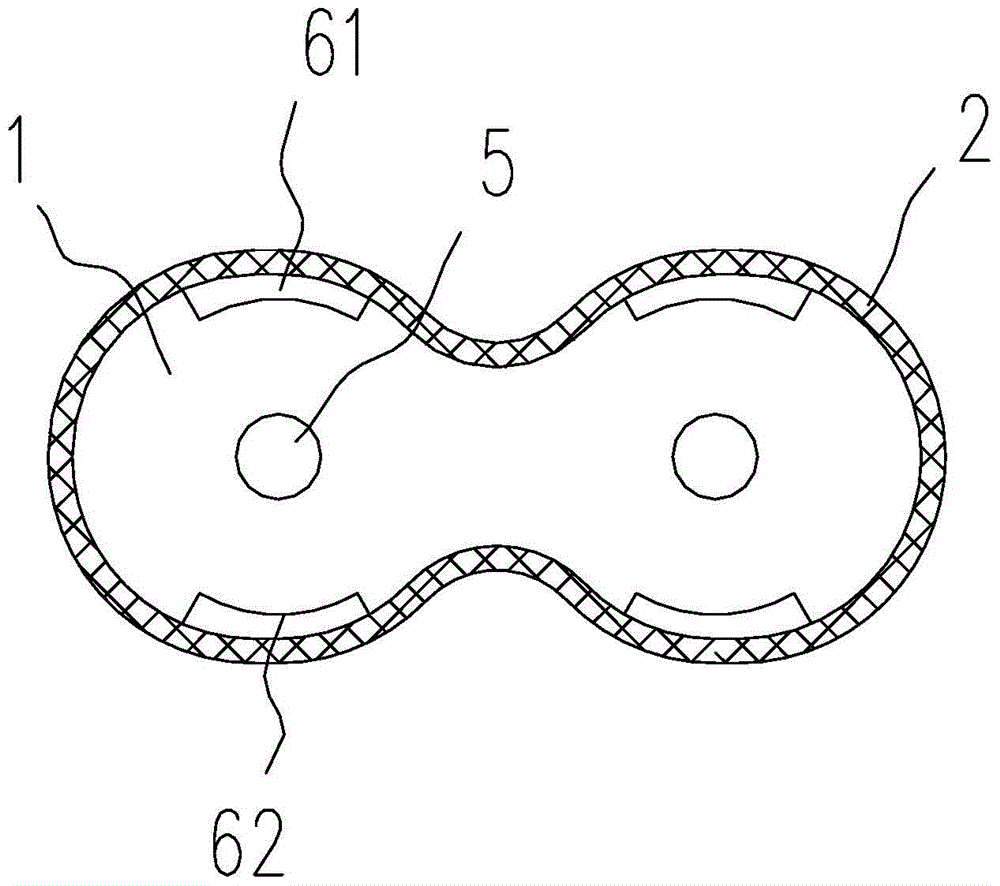

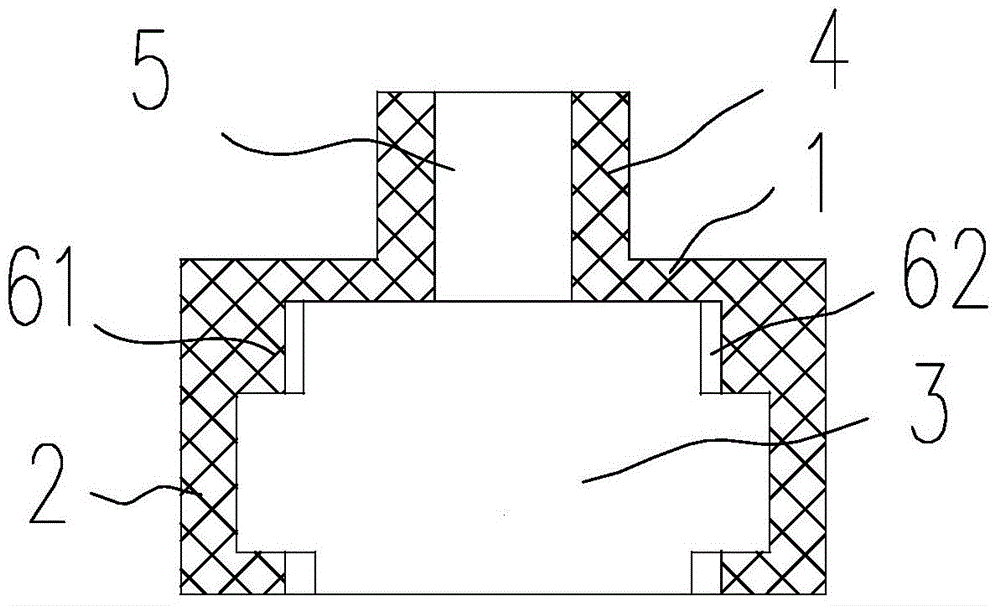

[0012] Such as figure 1 , figure 2 and image 3 As shown, the cover body 1 is made of waste electrical polypropylene film; the lower end of the cover body 1 has a cavity 3 for the two terminals on the top of the capacitor to be embedded, and the inner side of the cavity side wall 2 is formed by protruding into the cavity 3 The two snap ring fixing seats 6 used to be fixed on the capacitor terminals through the sleeve, the two snap ring fixing seats (6) respectively correspond to the two terminals of the capacitor, and the inner wall of each snap ring fixing seat 6 is arc-shaped .

[0013] There are through holes 5 on the top of the cover body 1 for the lead wires of the corresponding terminals to pass through. The upper end of the cover body 1 is provided with an upwardly protruding sleeve 4 around each through hole 5, and the height of the sleeve tube 4 is 3-5mm.

[0014] Considering the convenience of fixing, each snap ring fixing seat 6 is composed of two symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com