Method suitable for laser welding assembly of rectangular voice coil motor

A laser welding and voice coil motor technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of voice coil motor assembly accuracy not meeting requirements, damage, and increasing production costs of enterprises, and achieve large-scale Mass production, stable spacing distance, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will describe in detail with reference to the drawings in the embodiments of the present invention.

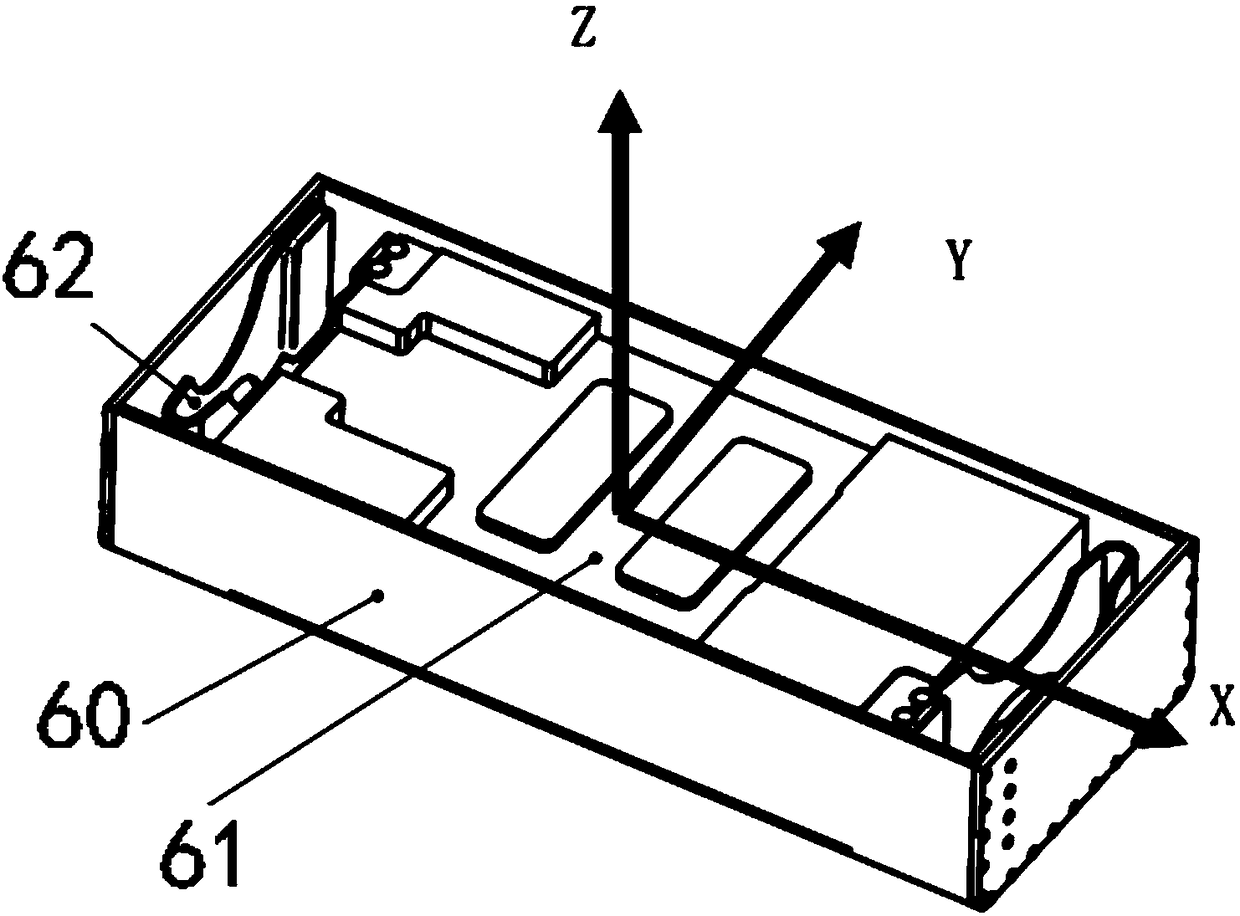

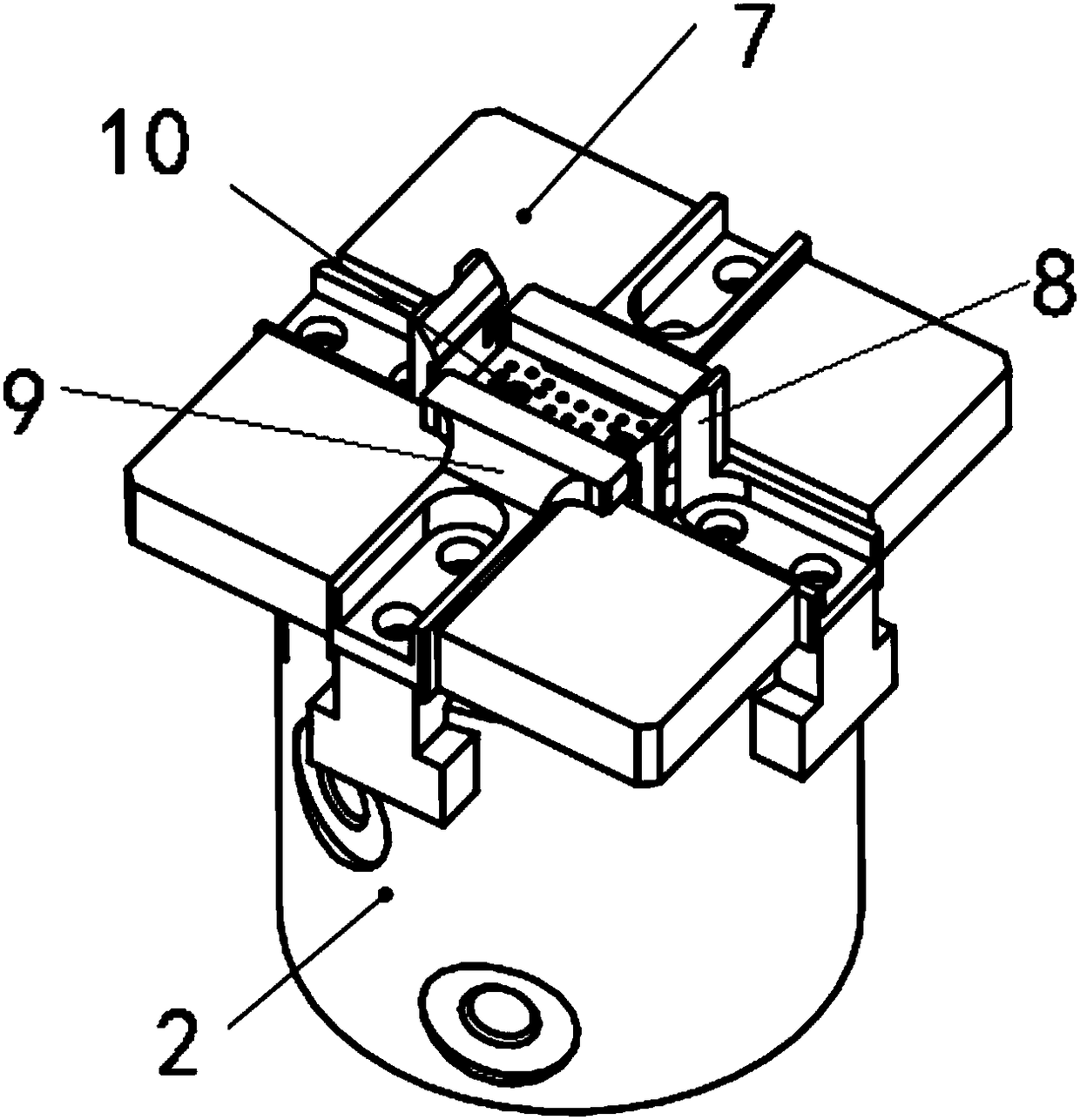

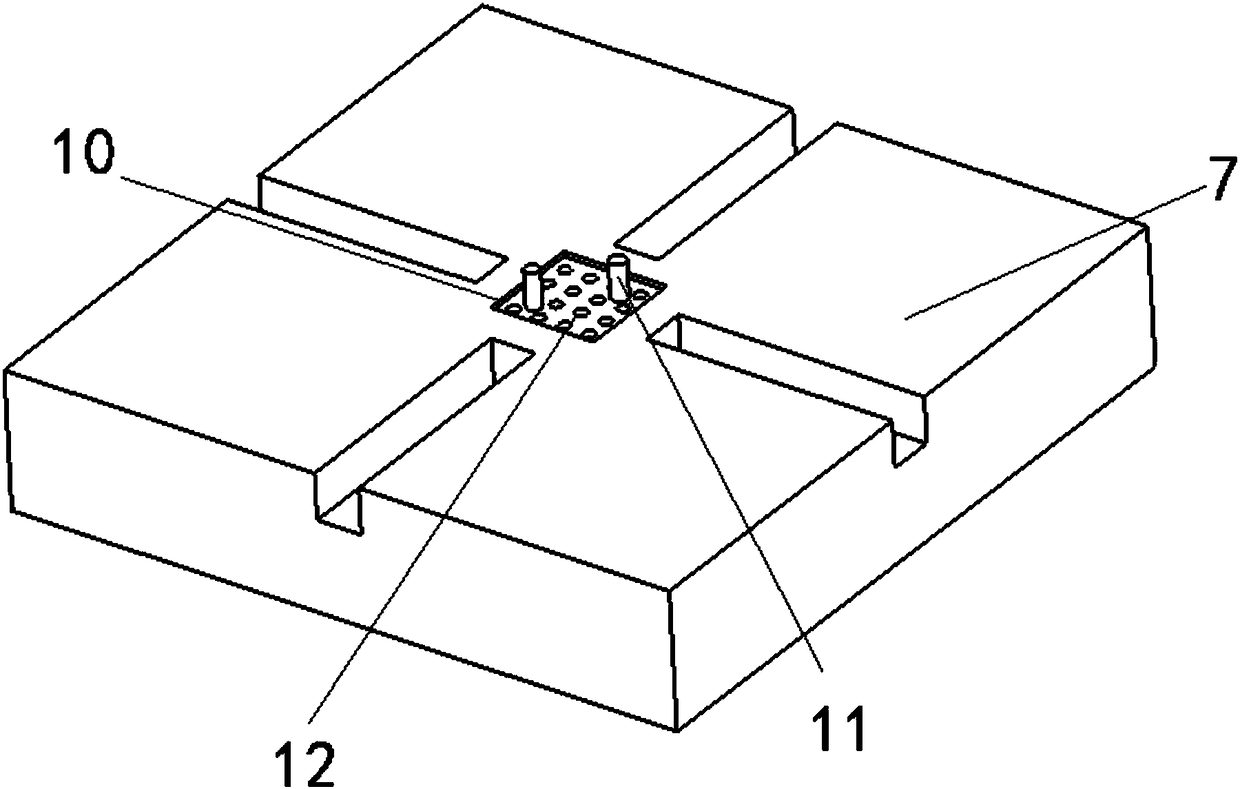

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , a method for laser welding and assembly of rectangular voice coil motors, the first step is to fix the shell assembly 60 of the product on the positioning area 10 of the working base 7, and make the pins 11 of equal height in the positioning area 10 pass through The hollow part of the housing assembly 60 . In the second step, the shell assembly 60 is sucked and fixed in the Z-axis direction through the sucking hole 12 on the sucking bottom plate. In the third step, use the four-claw clamp 2 to position the housing assembly 60 in both directions of the X and Y axes to the middle at the same time. Fourth, positioning the positioning mechanism with a pair of tabs 27 to the inner side wall of the housing assembly 60 . In the fifth ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com