Electric motor rotor, electric motor and direct current variable frequency compressor

A motor and rotor technology, which is applied in the fields of motor rotors, motors and DC variable frequency compressors, can solve the problems of difficulty in designing the optimal pole arc coefficient and the limitation of the mechanical strength of the magnetic isolation magnetic bridge, so as to reduce the no-load back electromotive force harmonics. Distortion rate, reduce noise and vibration, and improve the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

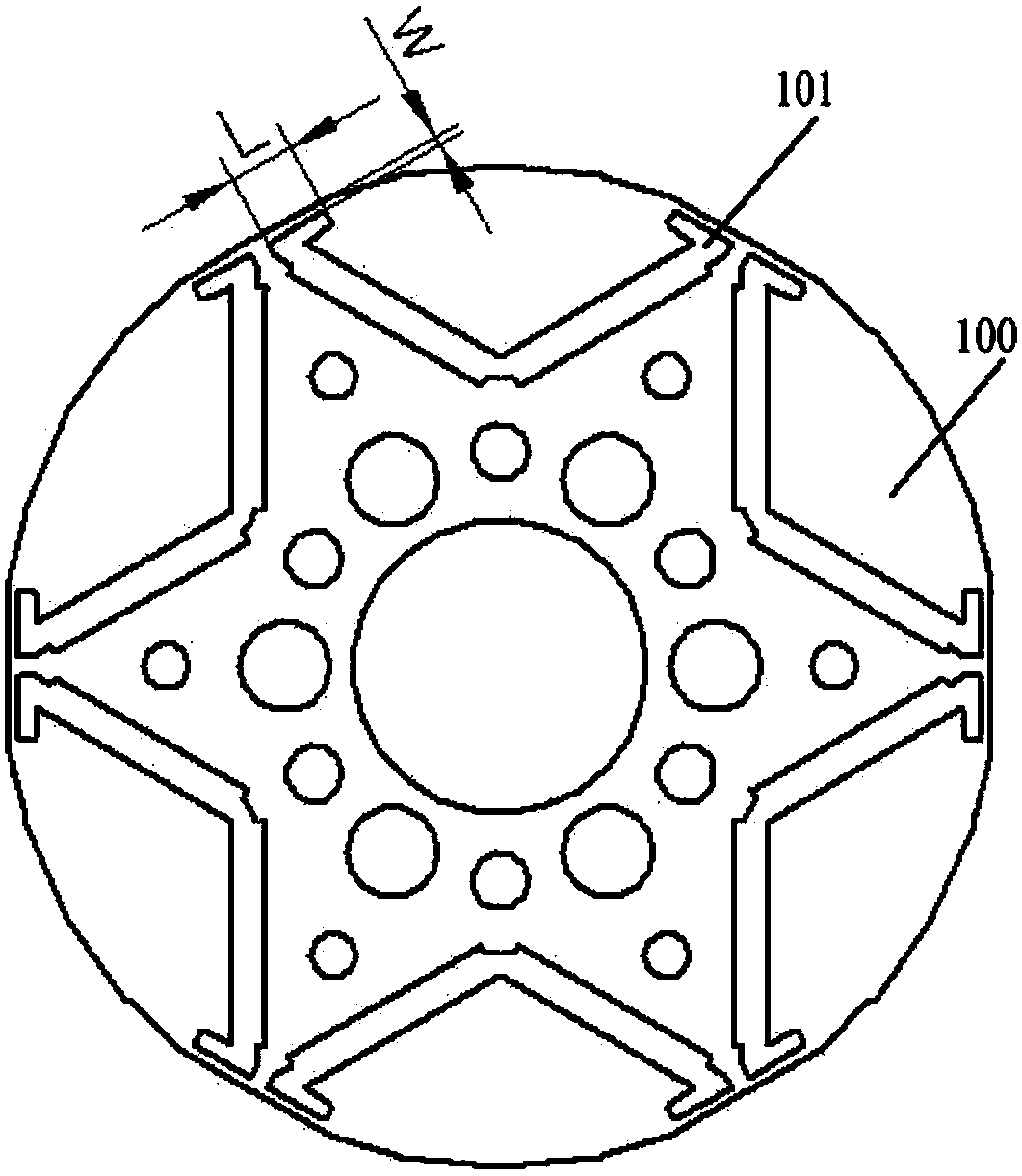

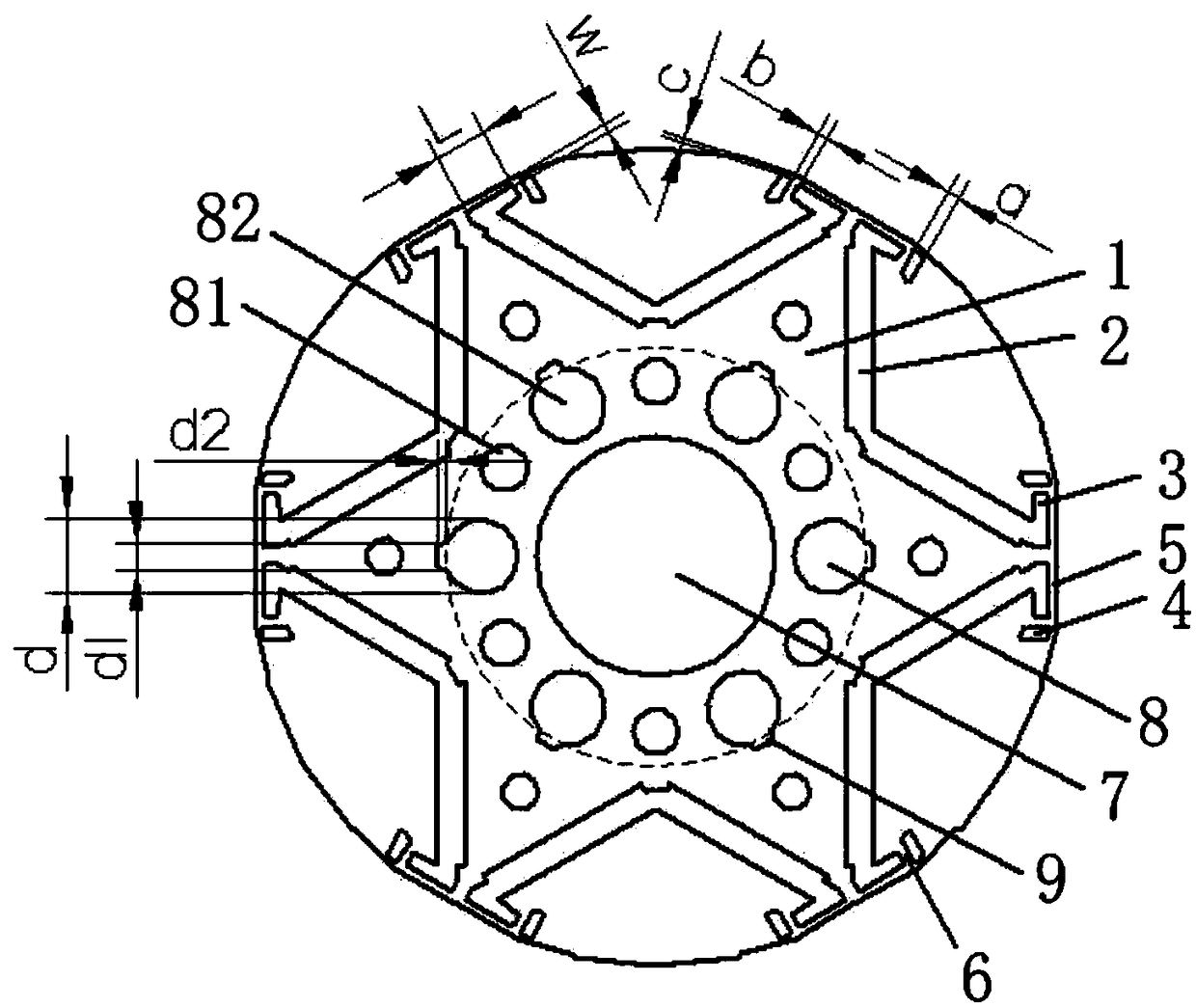

[0022] This embodiment provides a motor rotor, the rotor core 1 of the motor rotor includes rotor punches of the same shape, and the rotor punches are composed of the rotor punches through riveting or welding. figure 2 In the structure shown, the rotor core 1 is provided with a magnet slot 2, a magnetic isolation slot 3 and a magnetic flux arrangement slot 4, the magnet slot 2 is used for embedded and fixed installation of permanent magnets, and the magnetic isolation slot 3 is connected to At the end of the magnet slot 2 close to the edge of the rotor core 1, there is a magnetic isolation bridge 5 between the magnetic isolation slot 3 and the edge of the rotor core 1, and the magnetic flux finishing slot 4 is arranged in parallel One side of the magnetic isolation slot 3 is close to the edge of the rotor core, and the magnetic flux arrangement slot 4 is spaced from the magnetic isolation slot 3 to form a magnetic bridge 6, the magnetic flux arrangement slot 4 and the The dis...

Embodiment 2

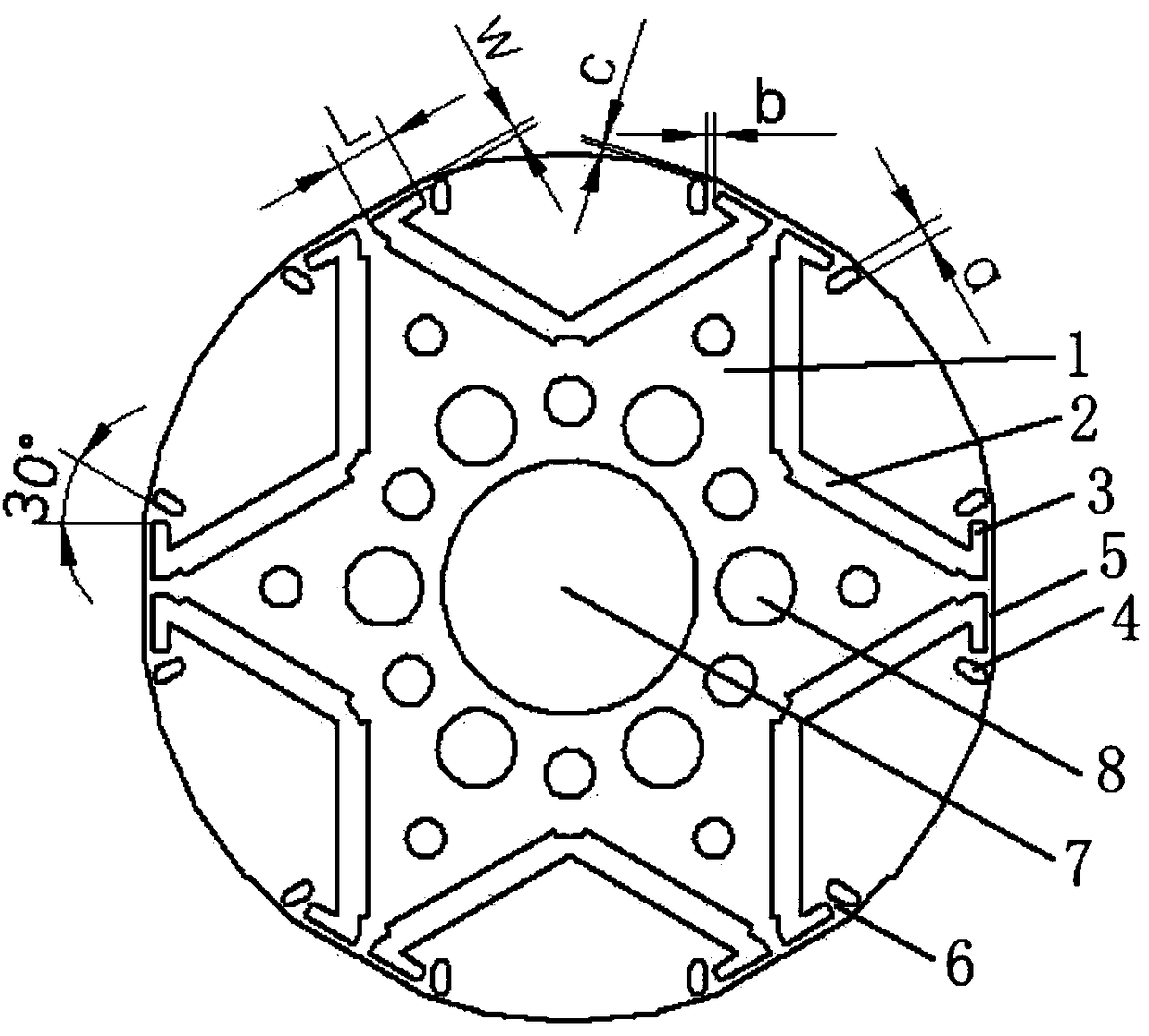

[0033] This embodiment provides a motor rotor, the rotor core 1 of the motor rotor includes rotor punches of the same shape, and the rotor punches are composed of the rotor punches through riveting or welding. image 3 In the structure shown, the rotor core 1 is provided with a magnet slot 2, a magnetic isolation slot 3 and a magnetic flux arrangement slot 4, the magnet slot 2 is used for embedded and fixed installation of permanent magnets, and the magnetic isolation slot 3 is connected to At the end of the magnet slot 2 close to the edge of the rotor core 1, there is a magnetic isolation bridge 5 between the magnetic isolation slot 3 and the edge of the rotor core 1, and the magnetic flux finishing slot 4 is arranged on the One side of the magnetic isolation slot 3 is close to the edge of the rotor core, and an acute angle is formed between the magnetic flux arrangement slot 4 and the magnetic isolation slot 3, and the distance between the magnetic flux arrangement slot 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com