Antenna, manufacturing method thereof, and electronic device

An electronic equipment and antenna technology, applied in antennas, antenna parts, antenna supports/mounting devices, etc., can solve the problems of motherboard layout influence, metal integrated mobile phone space occupation, large space occupation, etc., to achieve signal reception and transmission Good ability, enhanced market competitiveness, high complexity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following describes the embodiments of the present invention in detail, and those skilled in the art will understand that the following embodiments are intended to explain the present invention, and should not be regarded as limiting the present invention. Unless otherwise specified, in the following examples that do not explicitly describe specific techniques or conditions, those skilled in the art can carry out according to commonly used techniques or conditions in this field or according to product instructions.

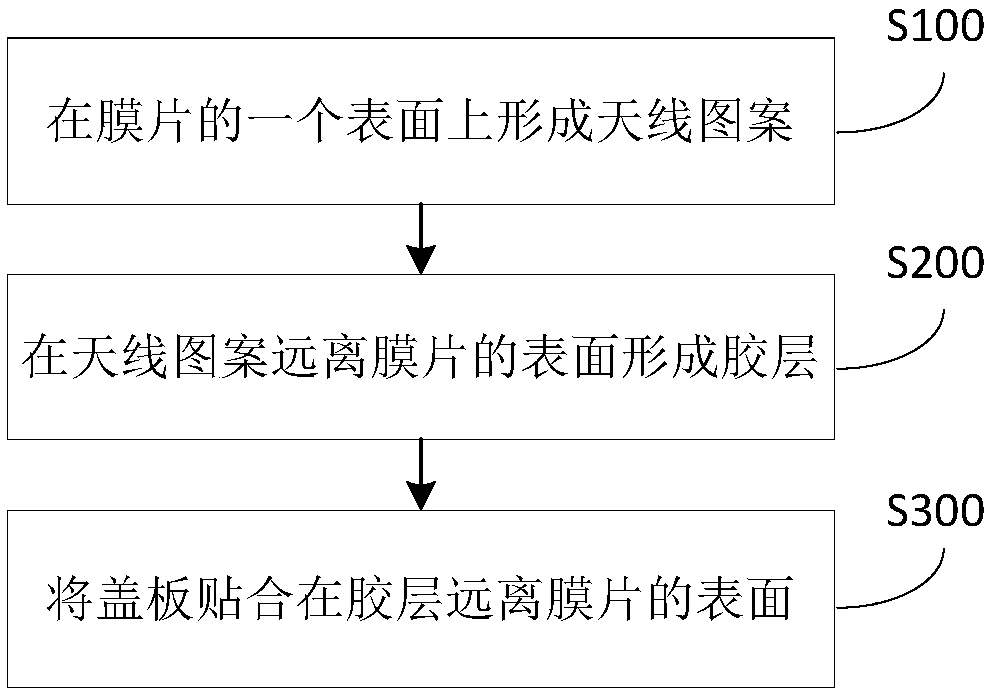

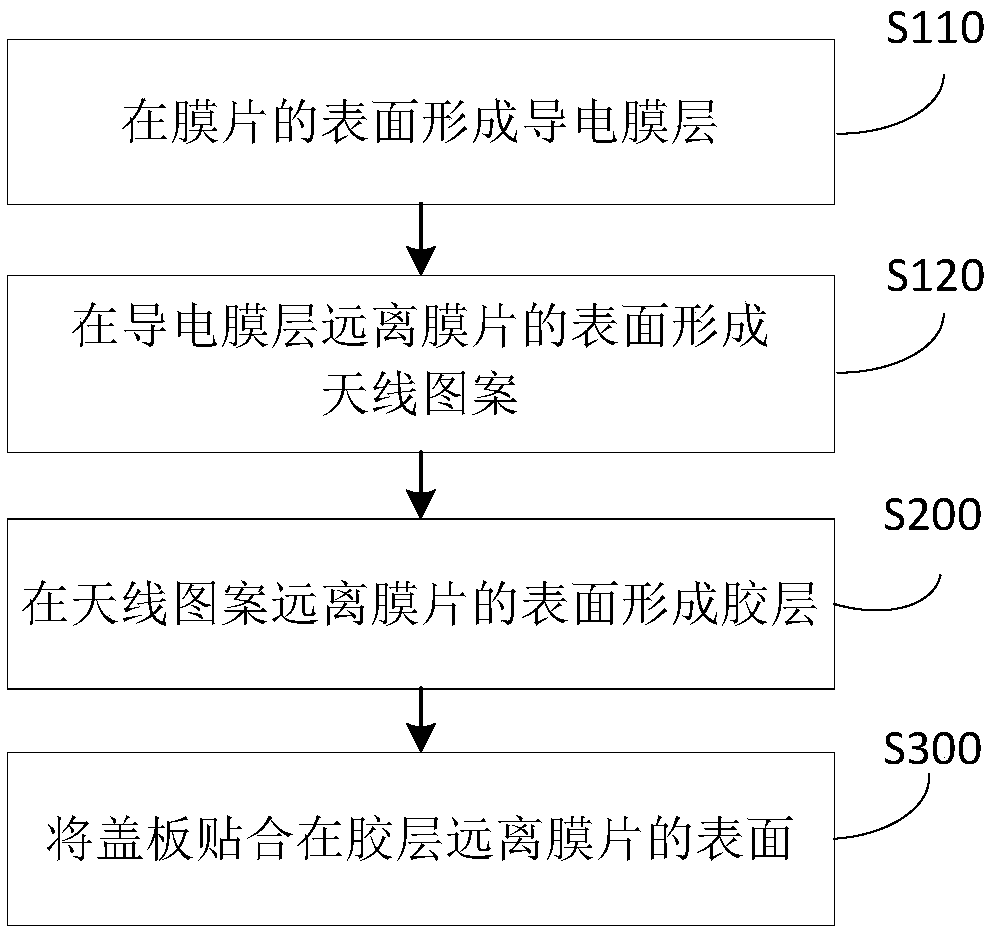

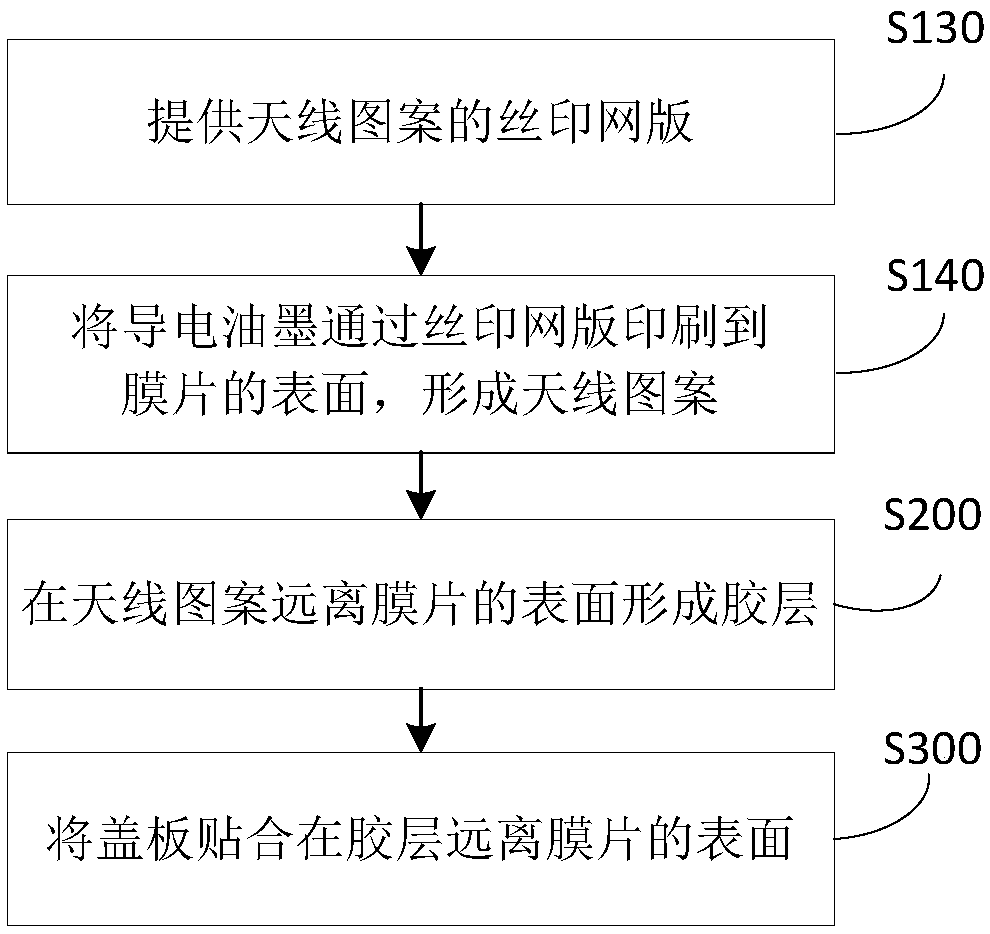

[0033] In one aspect of the embodiments of the present invention, a method for manufacturing an antenna is provided. According to an embodiment of the present invention, refer to figure 1 , the production method includes:

[0034] S100: Forming an antenna pattern on one surface of the diaphragm.

[0035] In this step, the antenna pattern 200 is first formed on one surface of the diaphragm 100 , so that the diaphragm 100 has no space restriction on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com