Offshore anti-typhoon wind power generation system

A wind power generation system and anti-typhoon technology, which is applied in the direction of wind power generation, wind power engine, wind power motor combination, etc., can solve the problems of transmission gear fatigue fracture, large amount, time, and cost are not allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is an offshore typhoon wind power generation system.

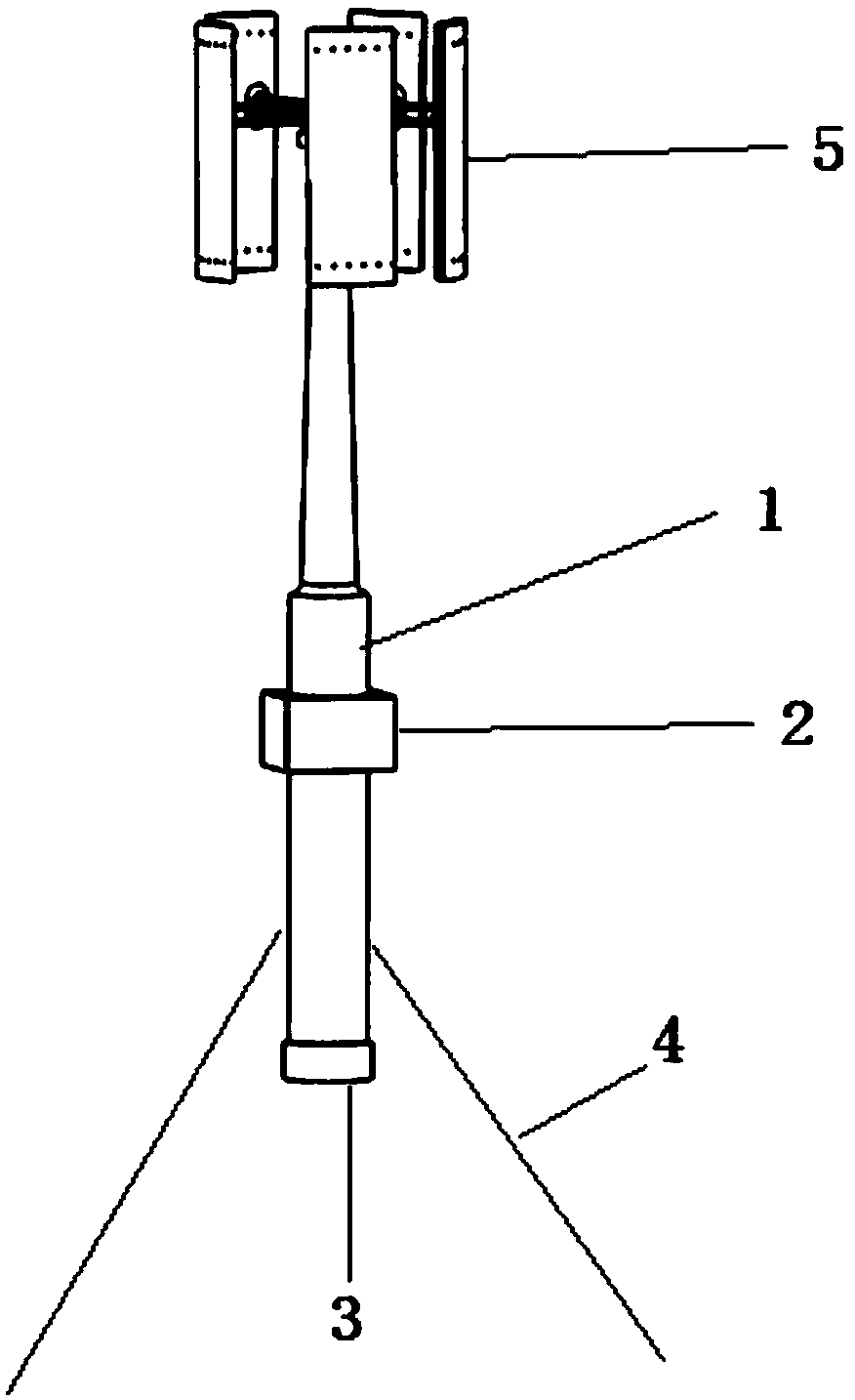

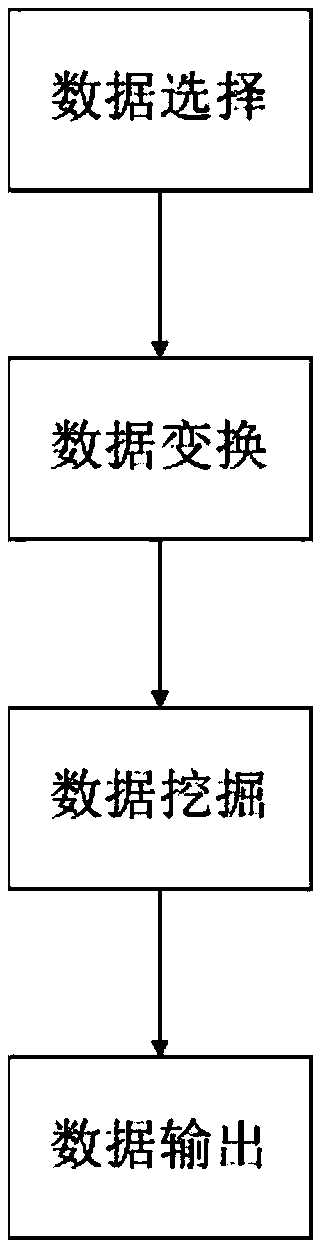

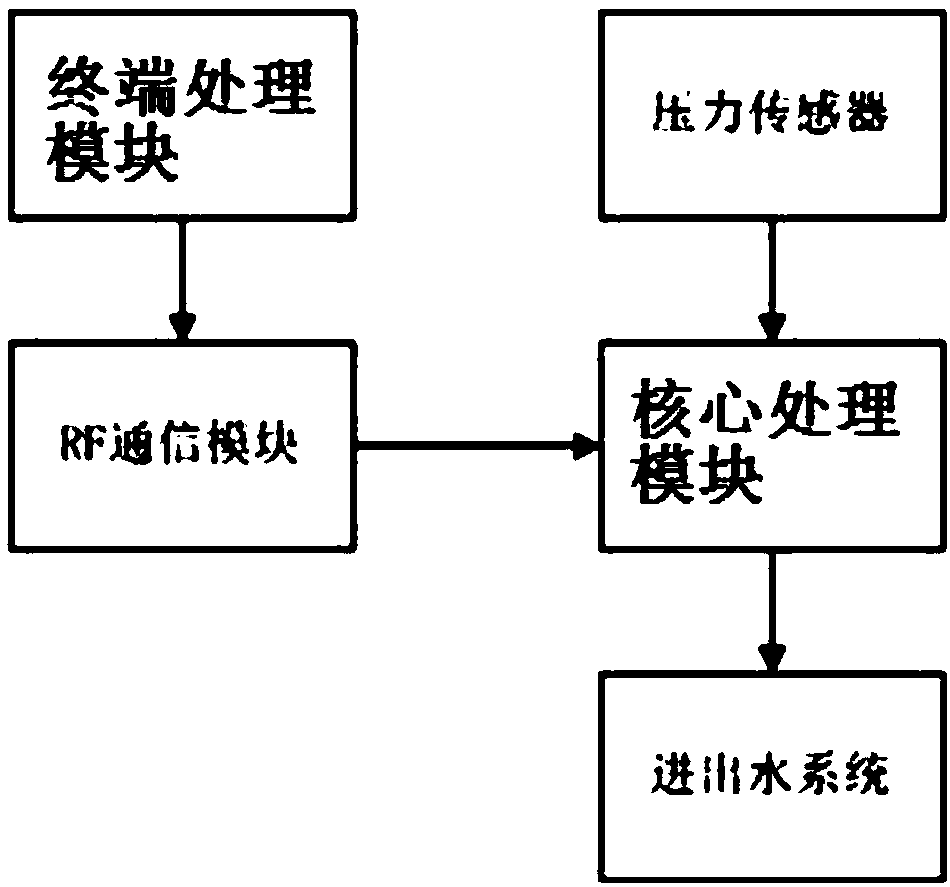

[0019] Refer to Figure 1 ~ Figure 3 The offshore typhoon wind power generation system of this embodiment is composed of a terminal processor, a control device 2, a buoy 1, a counterweight 3, a cable 4 and a power generating fan; wherein the upper end of the buoy 1 is connected to the power generating fan 5 through a connecting rod , The lower end of the pontoon 1 is fixedly connected to the counterweight 3. The counterweight 3 is located underwater for stabilizing the pontoon 1, and the control device 2 is fixed on the upper part of the pontoon 1; one end of the cable 4 is fixedly connected to the control device 2 and the counterweight 3 Between the pontoon 1, the other end of the cable is fixed on the seabed. The control device 2 includes an RF communication module, a core processor, a pressure sensor, and a water inlet and outlet device; the RF communication module receives instructions from the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com