Hydraulic control static setting through pipeline packer

A packer and hydraulic control technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problem that mechanical setting cannot be used, and oil casing annulus cannot be pressurized and set, etc. problem, to avoid the effect of high pressure friction

Pending Publication Date: 2018-12-28

CHUANNAN ENERGY TECH CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the above-mentioned problems existing in the prior art, and to provide a hydraulically controlled hydrostatic setting penetrating pipeline packer. The technical problem of adopting mechanical setting, and it can be well used in multi-layer intelligent completion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

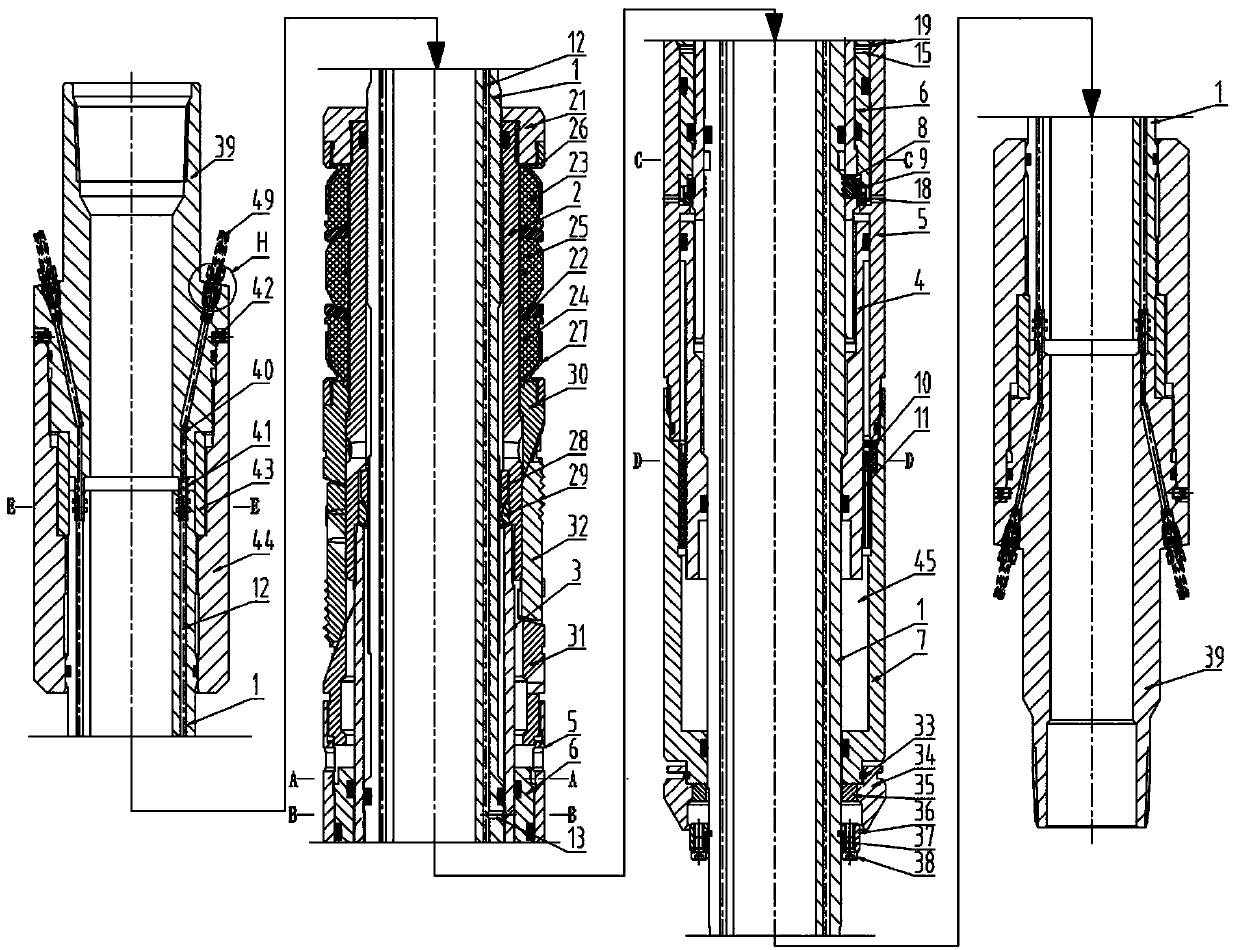

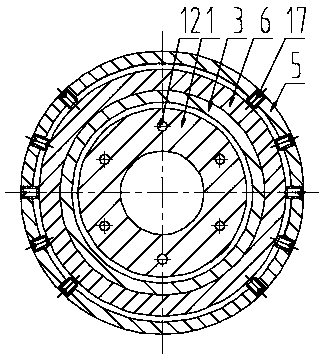

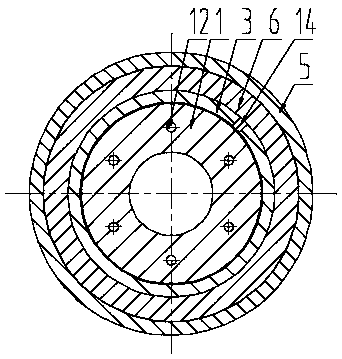

The invention discloses a hydraulic control static setting through pipeline packer. The hydraulic control static setting through pipeline packer comprises a central pipe, a sealing barrel, a connecting barrel, a locking barrel, an outer barrel, an unlocking casing, a sealing module, a slip module, a limiting ring, an anti-rotating ring, a one-way locking ring and a shear module. The hydraulic control static setting through pipeline packer can form an internal sealed pressure transfer channel to achieve static hydraulic setting, avoid the limitations that pressurized seating via an oil casing pipe cannot be achieved inside an electric pump production well as well as that high pressurizing frictional resistance of control pipelines and low flowing speed of hydraulic oil result in slow setting. Meanwhile, the hydraulic control static setting through pipeline packer can solve the technical problem that oil jacket annulus pressurized setting and mechanical setting are inapplicable in the prior art, thereby being well applicable to multi-layer intelligent well completion and identical in function to common hydraulic setting recoverable packers.

Description

technical field The invention belongs to the field of intelligent completion of oil and gas field development technology, and in particular relates to a hydraulically controlled hydrostatic setting traversing pipeline packer, which can be unlocked through a hydraulic control method and controlled by hydrostatic column pressure to control the packer setting, and has traversing control at the same time. New packers for pipelines. Background technique A packer is a downhole tool installed in an oil and gas well to seal the annulus, isolate the target layer, control the injection or production of fluid, and withstand a certain pressure difference. According to the setting method, it is usually divided into hydraulic setting, mechanical setting and self-sealing or expanding packer. In the field of smart completions, hydraulically set retrievable packers are commonly used. Oil recovery is usually divided into natural injection recovery and artificial lift recovery. For now, in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B33/129E21B33/128E21B33/1295

CPCE21B33/128E21B33/129E21B33/1295Y02E10/20Y02E10/10

Inventor 曹大勇蒋文王助伟

Owner CHUANNAN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com