Setting machine

A setting machine and steam setting technology, which are applied in textile and paper making, liquid/gas/vapor removal, and textile material processing, etc., can solve the problems of large cloth cover area, low cloth cover setting efficiency, and labor intensity of workers, etc. Achieve the effect of improving the quality of shaping, improving the efficiency and quality of shaping, and saving manpower and time

Pending Publication Date: 2018-12-28

DONGGUAN KEMEI MACHINERY

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional method of shaping the cloth cover is to iron it manually with an electric iron. Because the heating area of the electric iron is small, the area of the cloth cover is large, and manual ironing is required for many times.

After one side of the cloth cover is ironed, it needs to be turned over to the other side of the cloth cover for ironing. This process not only leads to high labor intensity and low efficiency of setting the cloth cover, but also because different workers have different ironing proficiency , the quality of stereotypes can not be guaranteed uniformly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

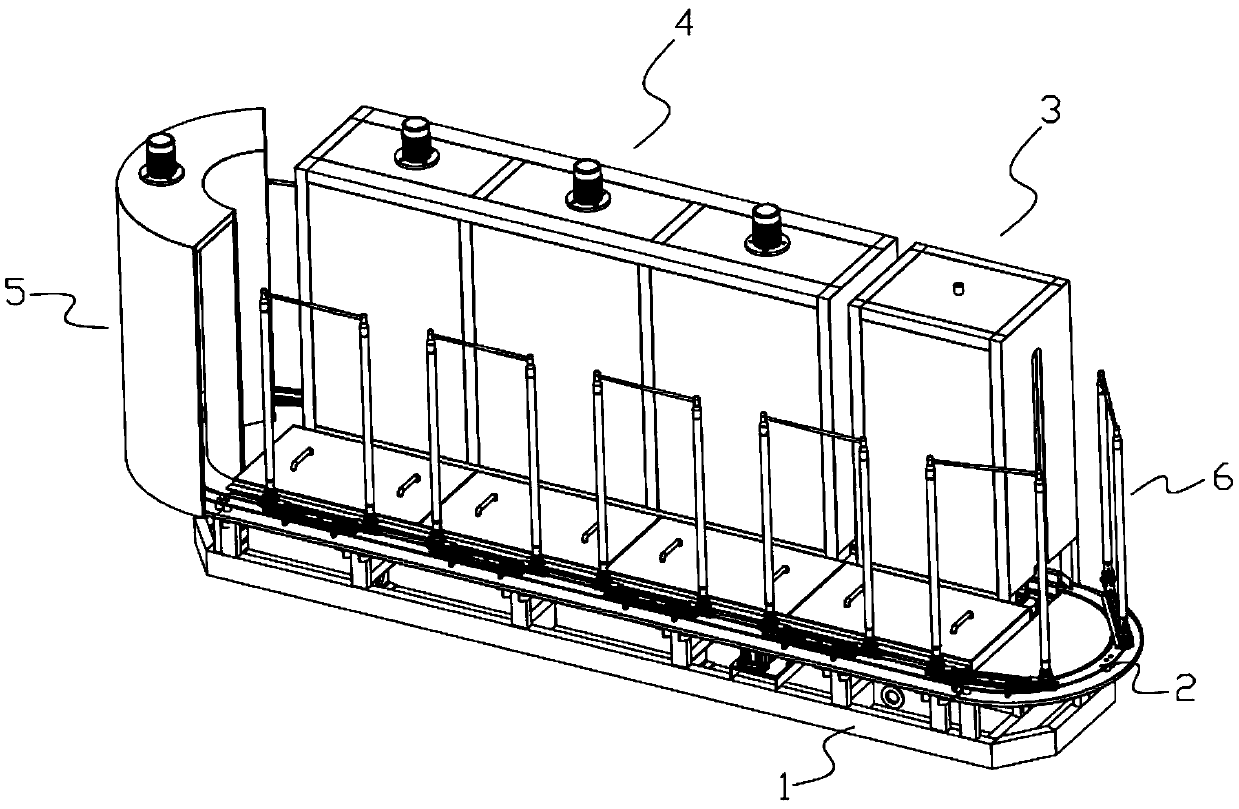

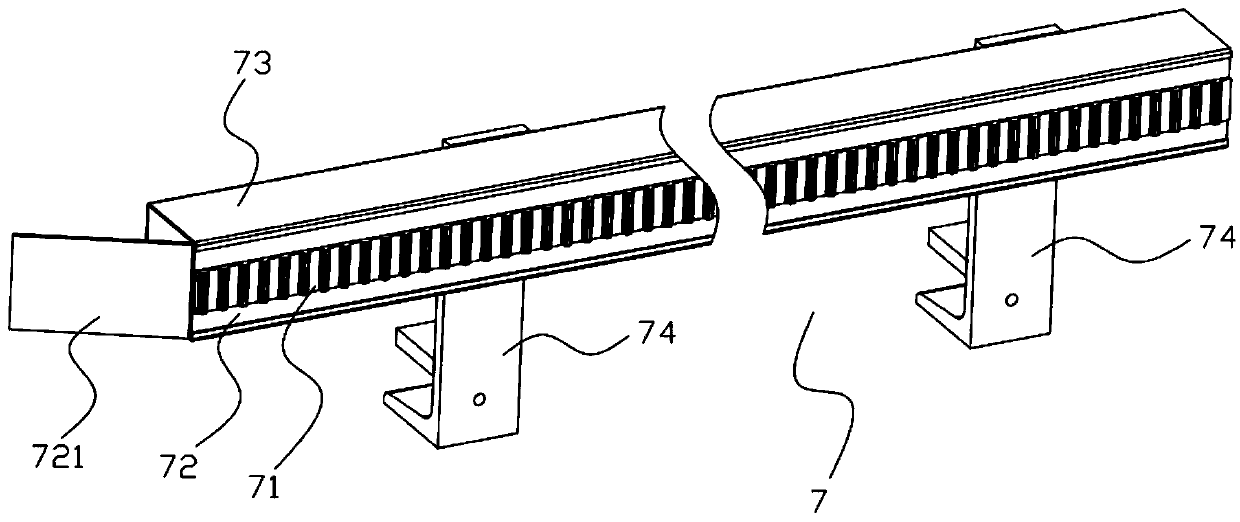

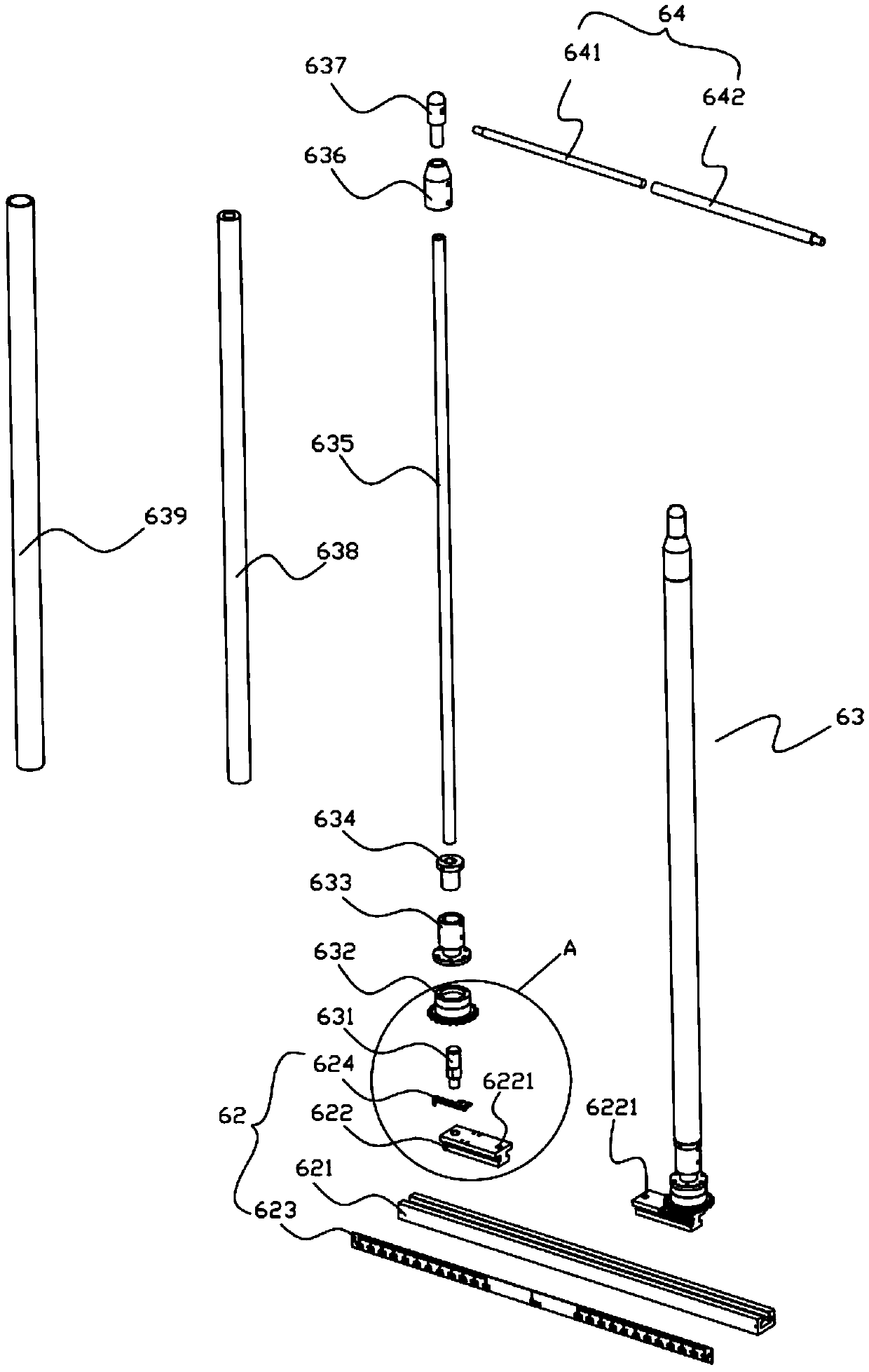

The invention discloses a setting machine which comprises a bottom frame, a conveying track, a steam setting tank, a drying device and a cooling device. The conveying track is arranged on the bottom frame, and the steam setting tank, the drying device and the cooling device are sequentially arranged on the conveying track. The setting machine is characterized by further comprises a plurality of rotary setting frames and a synchronous frame; the multiple rotary setting frames are arranged on the conveying track, and the synchronous frame is mounted on the bottom frame, is arranged in the steamsetting tank and the drying device; the synchronous frame meshes with the rotary setting frames and drives the rotary setting frames to carry out rotational movement when the rotary setting frames aredriven by the conveying track to move into the steam setting tank and the drying device along paths of the conveying track. Compared with the traditional setting modes, the setting machine has the advantages that manual operation can be replaced with machines, accordingly, large amounts of labor and time can be effectively saved, and the cloth cover setting efficiency and setting quality can be improved.

Description

technical field The invention relates to the field of sizing technology, in particular to a sizing machine for sizing cloth covers. Background technique After the cloth cover is woven, its surface presents an uneven shape, and the cloth cover needs to be shaped to make the surface smooth so as to increase the beauty and facilitate sales, while increasing flexibility and elasticity. The traditional method of shaping the cloth cover is to manually iron it with an electric iron, because the heating area of the electric iron is small, and the cloth cover area is large, so it needs to be manually ironed many times. After one side of the cloth cover is ironed, it needs to be turned over to the other side of the cloth cover for ironing. This process not only leads to high labor intensity and low efficiency of setting the cloth cover, but also because different workers have different ironing proficiency , The quality of the stereotypes can not be guaranteed uniformly. Contents ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B21/00D06B23/04D06B23/18D06B15/00

CPCD06B15/00D06B21/00D06B23/04D06B23/18

Inventor 吴大运喻珍爱

Owner DONGGUAN KEMEI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com