A kind of preparation method of vermiculite fluorescent film composite material

A thin-film composite material and vermiculite technology, which is applied in the direction of luminescent materials, chemical instruments and methods, coatings, etc., can solve the problems of insufficient development and utilization of vermiculite, short life of organic cationic phosphors, etc., and achieve the suppression of luminescence quenching phenomenon, Improve physical and chemical stability, solve the effect of poor stability

Active Publication Date: 2022-06-03

TARIM UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the problems of insufficient development and utilization of vermiculite and short service life of organic cationic phosphors, the purpose of the present invention is to provide a preparation method of vermiculite fluorescent film composite material, which combines macroscopic vermiculite and organic cationic phosphors to form a composite material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0040] The specific embodiments are shown in the following examples.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Login to View More

Abstract

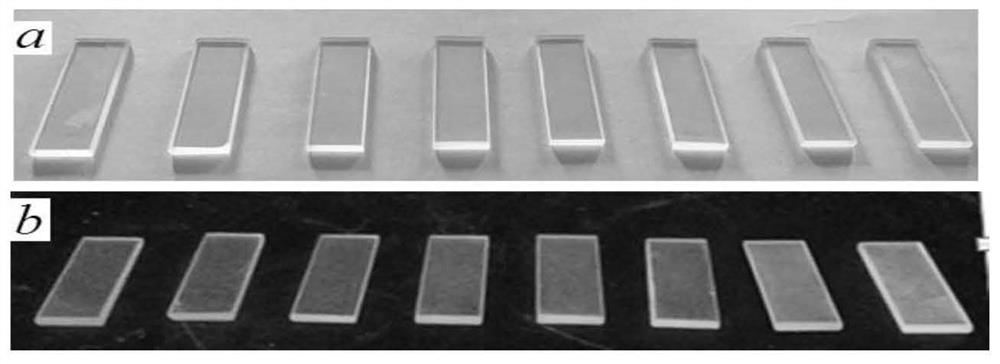

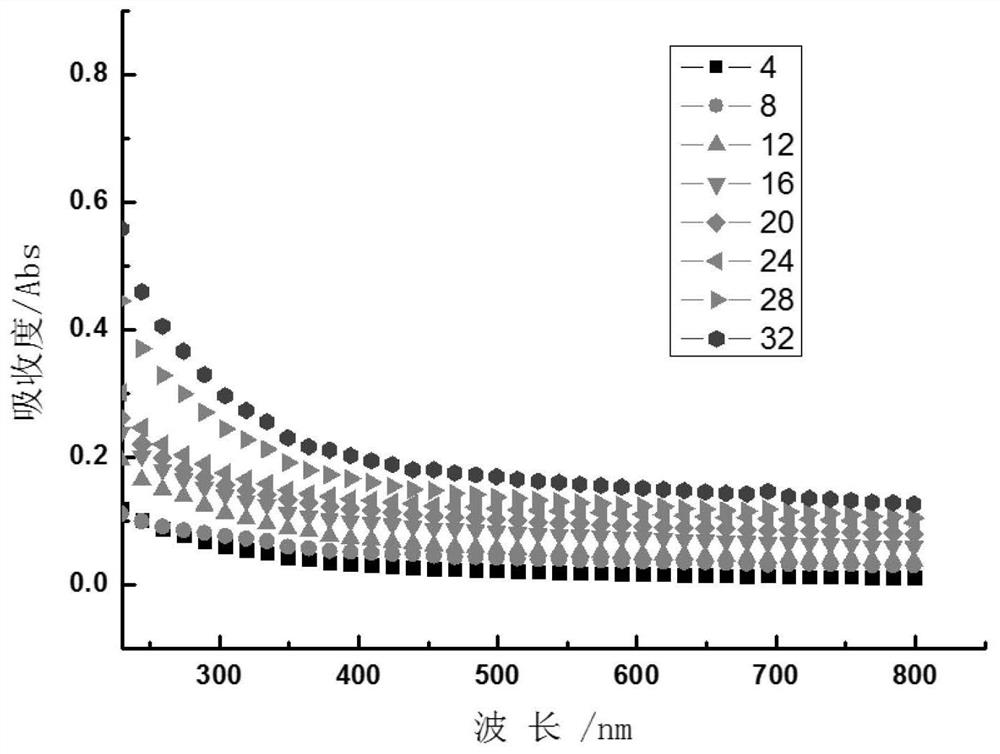

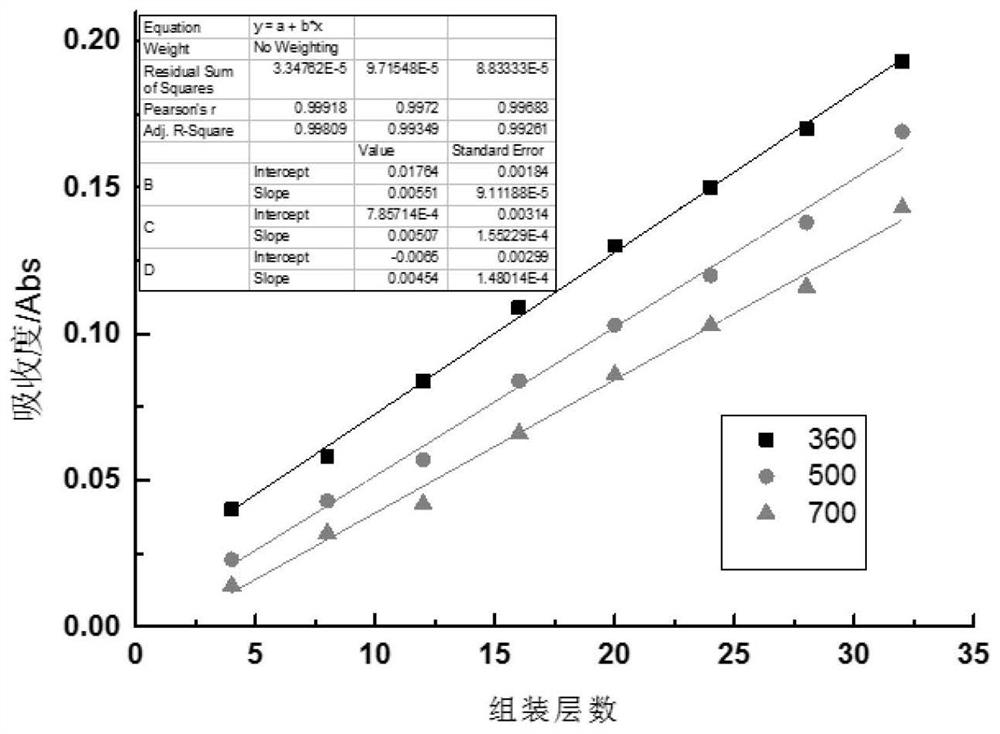

The invention provides a method for preparing a transparent fluorescent ultra-thin film composite material by using a layered vermiculite material and an organic fluorescent molecular material. It is prepared by a supramolecular assembly method, so that the prepared organic-inorganic fluorescent ultra-thin film composite material overcomes the simple organic fluorescent ultra-thin film composite material. materials and pure inorganic materials, and have the advantages of both, and realize the assembly of anion and anion body at the same time, the prepared fluorescent composite material has a longer fluorescence lifetime, has the characteristics of transparency and solidification, and has great High promotion and application value.

Description

A kind of preparation method of vermiculite fluorescent thin film composite material technical field The present invention relates to a kind of preparation method of fluorescent material, be specifically related to a kind of preparation method of vermiculite fluorescent thin film composite material. The preparation method belongs to the technical field of inorganic non-metallic mineral material processing. Background technique The definition of supramolecular assembly (Supramolecular assembly) is by the non-covalent bond and is assembled into the multi-molecules group, which can be as simple as two molecules, they can be spherical, rod-shaped or sheet-like samples, the study of supramolecular assembly is for In order to obtain a series of new materials, most of the building blocks studied in supramolecular assembly focus on the molecular and nanoscale, or micron scale. It can effectively control the performance of new materials and achieve a leap in product quality. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K11/02C08J7/06C08L67/02

CPCC09K11/025C08J7/06C08J2367/02

Inventor 田维亮葛振红马明叶林

Owner TARIM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com