Longitudinal slitting machine for bamboo shoots

A slicing machine, vertical technology, applied in the field of bamboo shoot processing, can solve the problems of inconvenient one-knife forming, single function, inconvenient bamboo shoot placement, etc., and achieve the effect of reducing labor intensity, improving cutting efficiency, and automatic cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

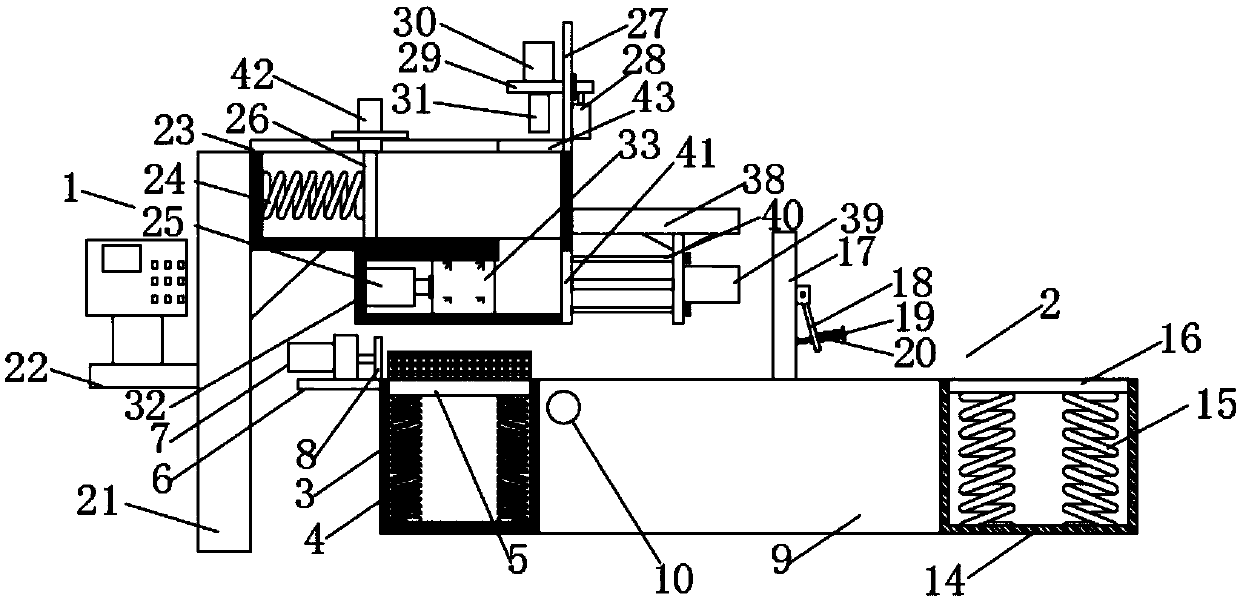

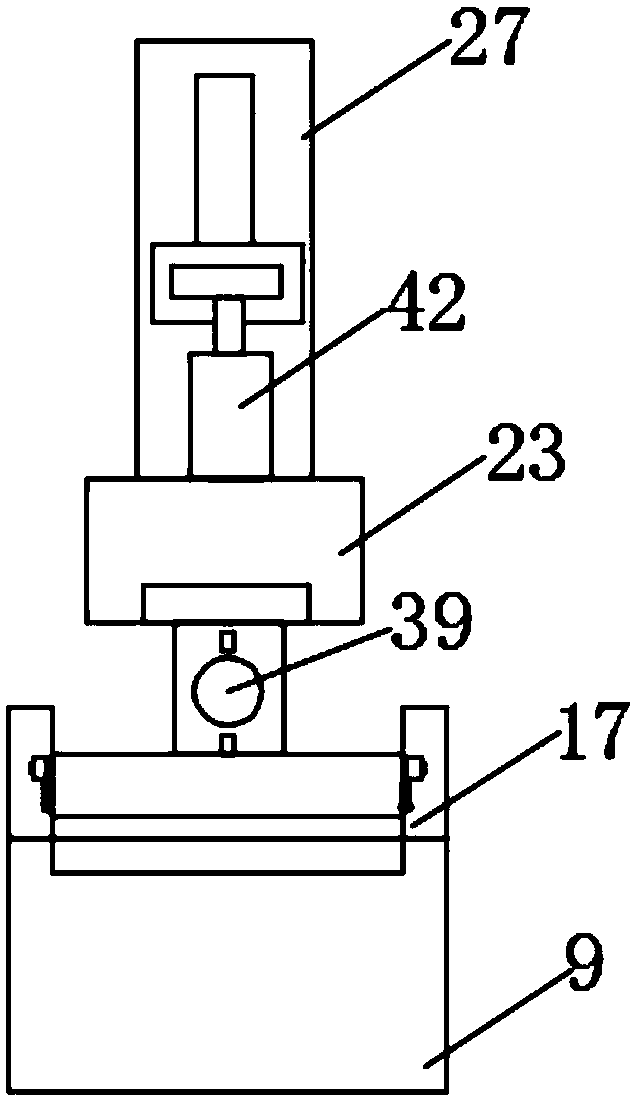

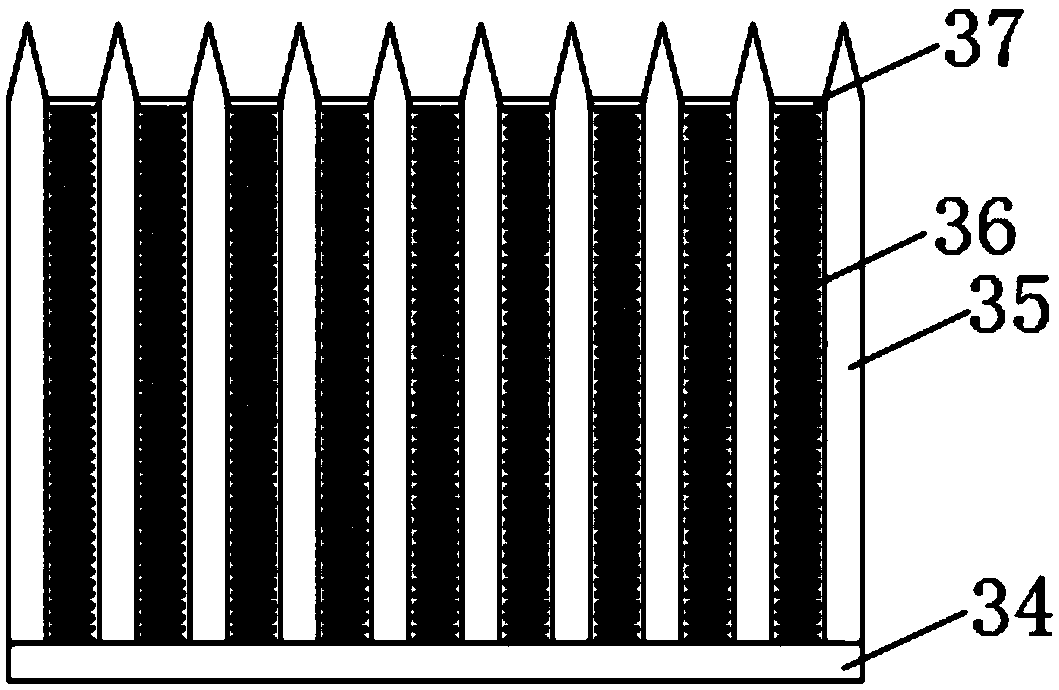

[0020] Such as Figure 1-4 As shown, the specific embodiment adopts the following technical solutions: a bamboo shoot longitudinal slicer, comprising a slicing mechanism 1 and a material receiving mechanism 2, the bottom of the slicing mechanism 1 is provided with a material receiving mechanism 2, and the described material receiving mechanism 2 Consists of shelf box 3, ejection spring 4, ejection slide plate 5, support plate 6, first cylinder 7, push plate 8, transmission box 9, conveying motor 10, first transmission roller 11, conveyor belt 12, second transmission roller 13. The material receiving box 14, shock absorbing spring 15, buffer plate 16, fixed support plate 17, tiled plate 18, limit slide bar 19 and buffer spring 20 are composed, and the two ends of the transfer box 9 are symmetrically rotated and connected with the second A driving roller 11 and a second driving roller 13, and the first driving roller 11 and the second driving roller 13 are connected by a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com