Meat grinder easy to disinfect, sterilize and clean

A technology of disinfection, sterilization, and meat grinder, which is applied in the field of meat grinders, can solve problems such as low work efficiency, waste of water resources, and difficult cleaning of cleaning devices, and achieve automatic cleaning operations, good disinfection and sterilization, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

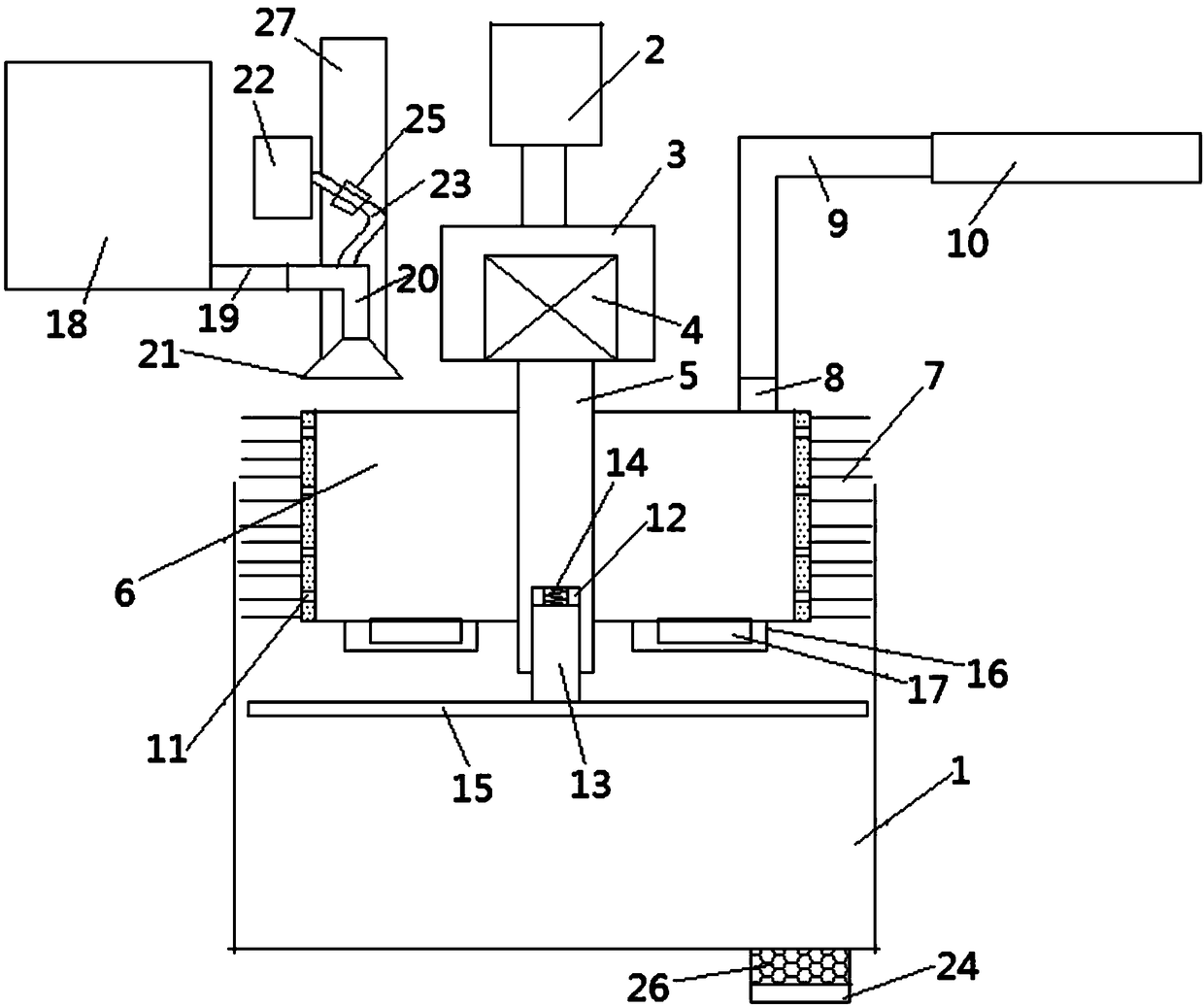

[0012] see figure 1 , a kind of meat grinder that is easy to sterilize, sterilize and clean, includes a meat grinder 1, a cylinder 2 is arranged above the meat grinder, the piston rod of the cylinder is vertically downward and the end of the piston rod is installed with a Seat 3, a rotating shaft 5 driven by a motor 4 is installed on the mounting seat; the outer casing of the rotating shaft 5 is equipped with a hollow outer sleeve 6, and the outer tube wall of the hollow outer sleeve is connected with an annular hair brush 7, and the bristles on the annular hair brush Scrub against the inner side wall of the meat grinder, the top of the hollow outer sleeve 7 is connected with a water inlet pipe 8, and the water inlet pipe is communicated with the main water pipe 10 through an elastic telescopic tube 9, and the pipe wall of the hollow outer sleeve 7 is provided with a A plurality of injection holes 11, the injection holes 11 extend and communicate with the annular brush 7 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com