Robot casting joint cleaning mechanism

A technology for robots and castings, applied in the field of robots, can solve the problems of residue residue, oil pollution on the joint surface of robot castings, and floating rust, and achieve the effect of preventing re-corrosion.

Inactive Publication Date: 2018-12-28

ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main purpose of the present invention is to provide a method for cleaning the joints of robot castings, so as to solve the problems that oil stains, floating rust, and various residues on the surface of robot casting joints are difficult to clean.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

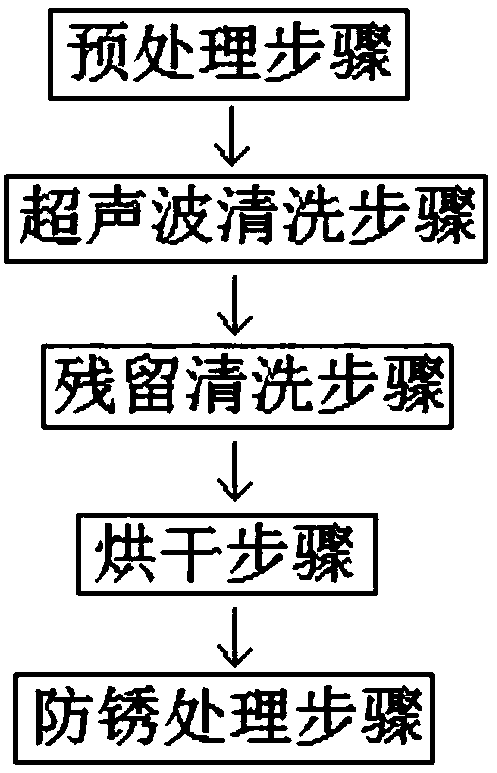

The invention provides a robot casting joint cleaning mechanism. The robot casting joint cleaning mechanism comprises an ultrasonic cleaning process including cleaning a robot casting joint into a cleaning tank containing cleaning agent aqueous solution through an ultrasonic cleaning device, a residue cleaning process including cleaning the ultrasonic-cleaned robot casting joint inside a clean water pond, a drying process including drying the cleaned robot casting joint inside a drying oven, and an anti-rust treatment process including spraying anti-rust agent onto the outer surface of the dried robot casting joint. Through the ultrasonic cleaning process, the residue cleaning process, the drying process and the anti-rust treatment process on the robot casting joint, the robot casting joint cleaning mechanism can clean oily dirt, rust and various residues on the surface of the robot casting joint, avoid re-corrosion of the robot casting joint and improve the robot casting joint oil-removing and cleaning efficiency.

Description

technical field The invention relates to the technical field of robots, in particular to a cleaning method for robot casting joints. Background technique Cast iron and cast aluminum joint parts are the main structural components of industrial robots. The blanks of the joint parts are cast outlines, with complex structures and rough surfaces. During the transportation, storage, and processing of castings, various oil stains, floating rust, and various residues have to be adhered to, which are difficult to remove, resulting in unstable adhesion of the paint layer on the sprayed surface of the castings, and prone to paint peeling, cracking, and cracking. Skin and other surface defects seriously affect the appearance quality of process robots. At present, the main problems that lead to the difficulty of cleaning the casting surface are: 1. Oil stains and residual substances on the surface have complex components and are difficult to dissolve. 2. The surface is rough, oil s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B3/12B08B3/04B08B13/00

CPCB08B3/04B08B3/12B08B13/00

Inventor 谢慧军陆明吴继青谢黎

Owner ZHUHAI GREE INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com