Screening device for building material processing ingredients

A technology for screening devices and building materials, applied in heating devices, sieves, solid separation, etc., can solve the problems of agglomeration, inability to fully screen materials, and high manufacturing costs, so as to avoid incomplete heating and drying, and solve the problem of sieving The effect of reducing the efficiency of separation and improving the efficiency of material screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

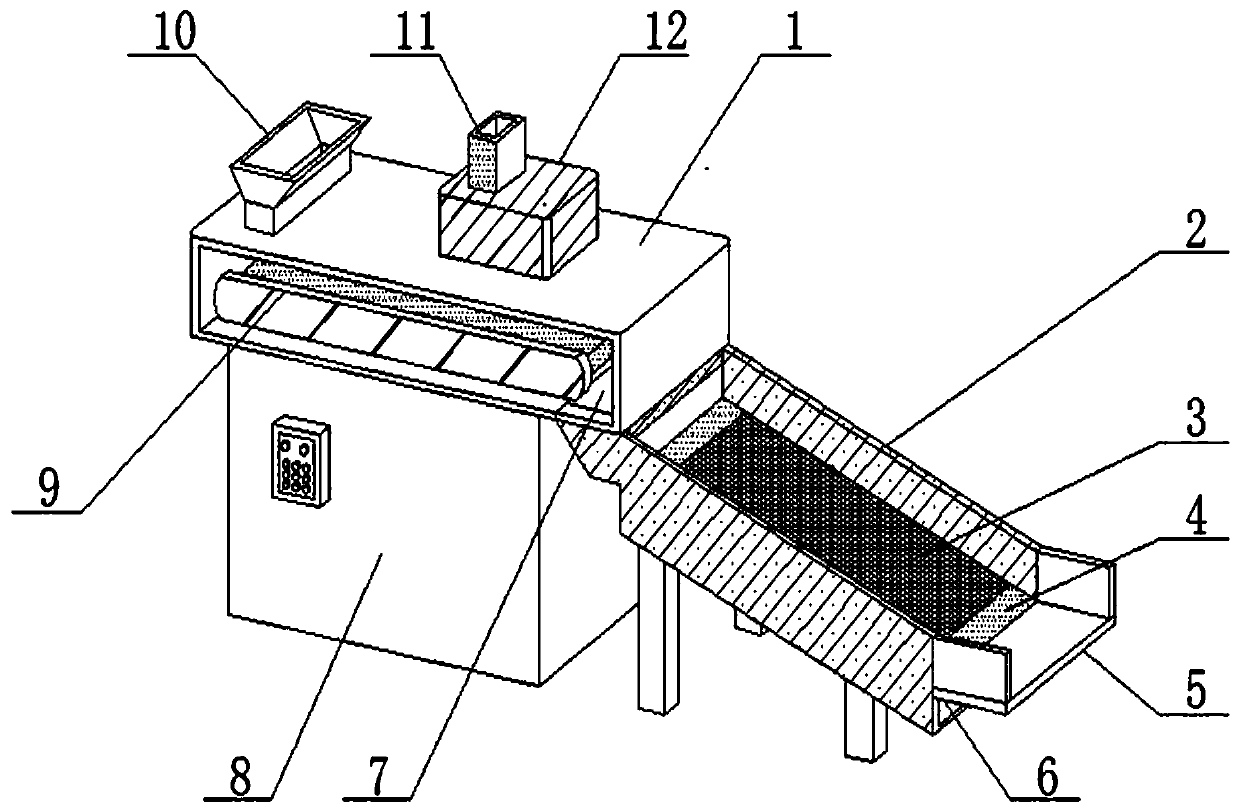

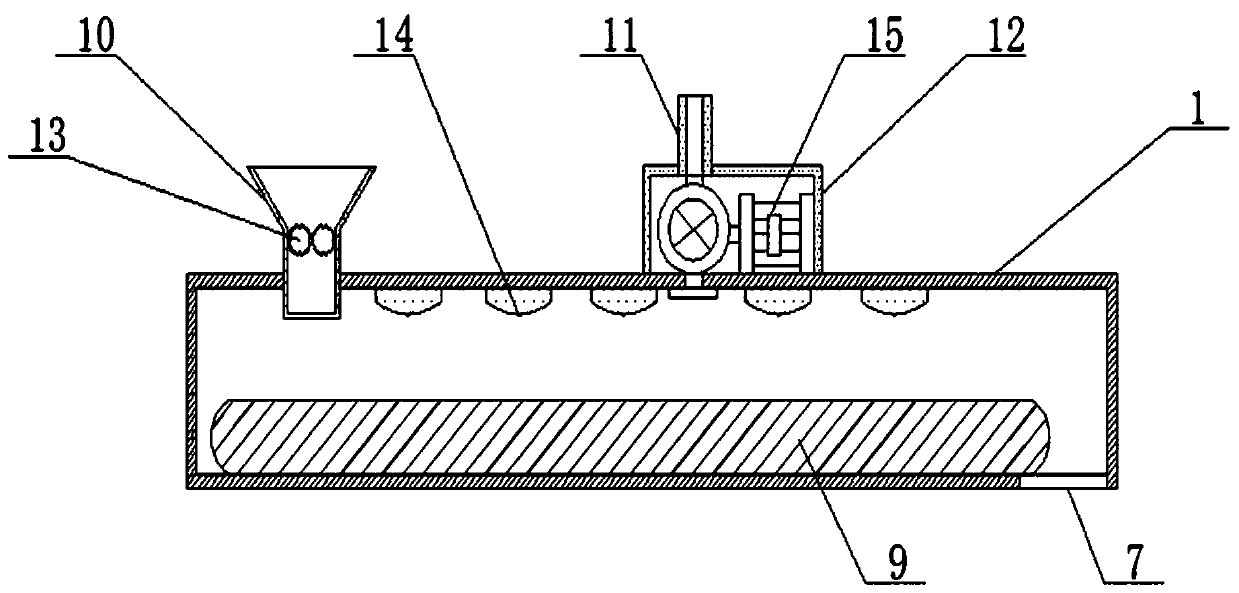

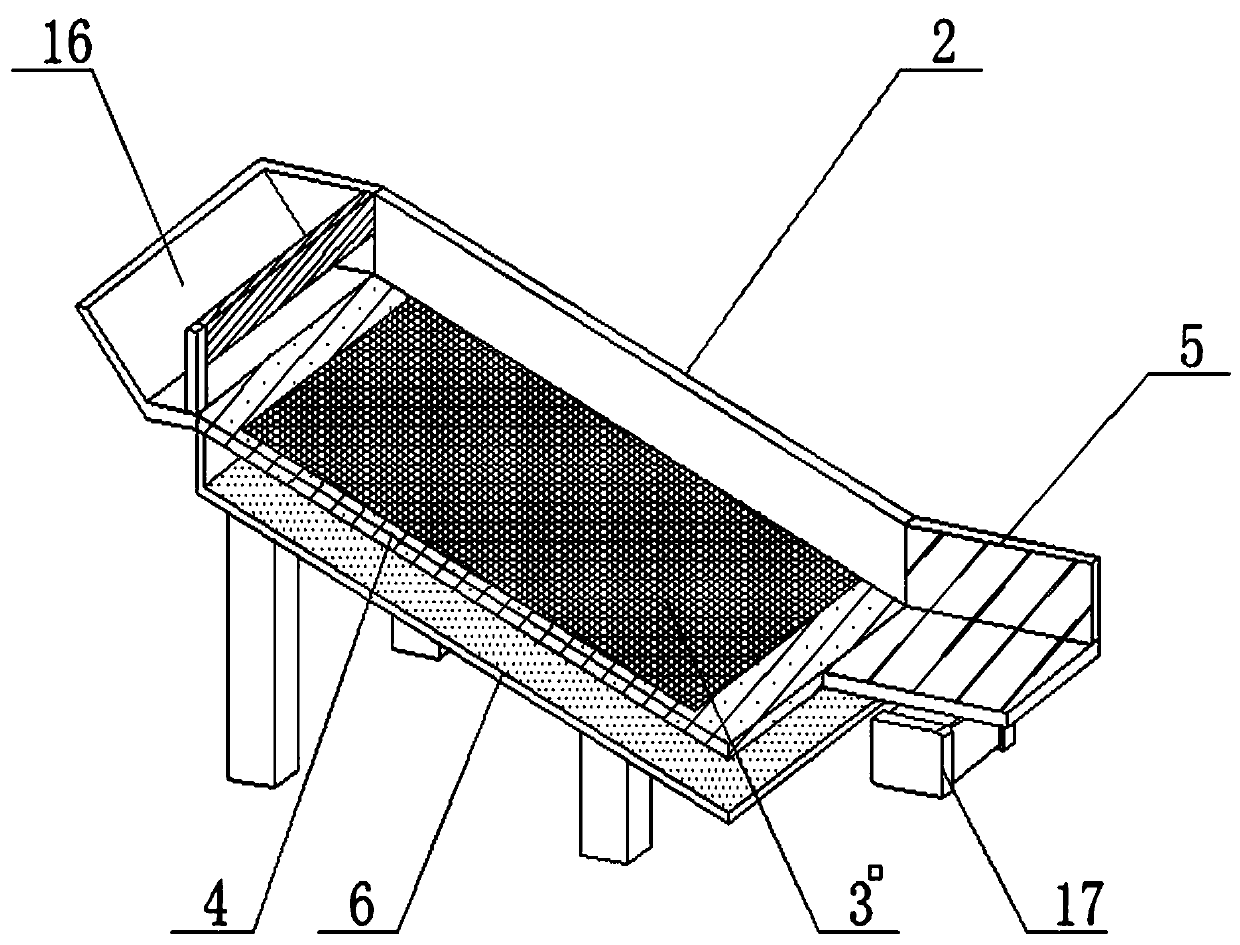

[0021] see Figure 1~3 , in an embodiment of the present invention, a screening device for processing ingredients for building materials includes a drying material box 1, a hopper 10 is connected to one end of the upper surface of the drying material box 1, and an organic box 12 is arranged in the middle of the upper surface of the drying material box 1, The upper end of the cabinet 12 is connected with a moisture discharge pipe 11, the lower end of the drying material box 1 is provided with an organic base 8, and one end of the lower surface of the drying material box 1 is provided with a discharge port 7, and a screening machine 2 is installed below the discharge port 7. One end of the extension machine 2 is provided with a feed port 16, and the other end of the screening machine 2 is connected with a discharge plate 5, and a vibration motor 17 is installed at the lower end of the discharge plate 5, and a The screen plate 4 is provided with a fixed plate 6 below the screen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com