Preparation method of surface imprinted particles capable of efficiently separating flavone molecules

A technology of surface imprinting and flavonoids, which is applied in the field of preparation of surface imprinted particles, can solve the problems of difficult separation of components with similar structures, low separation efficiency and recovery rate, and low purity of extracted drugs, achieving specific recognition selectivity and easy operation , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] step one:

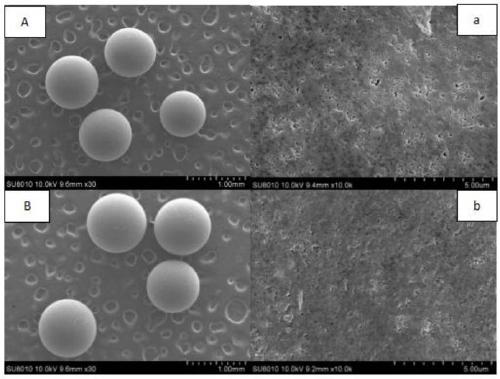

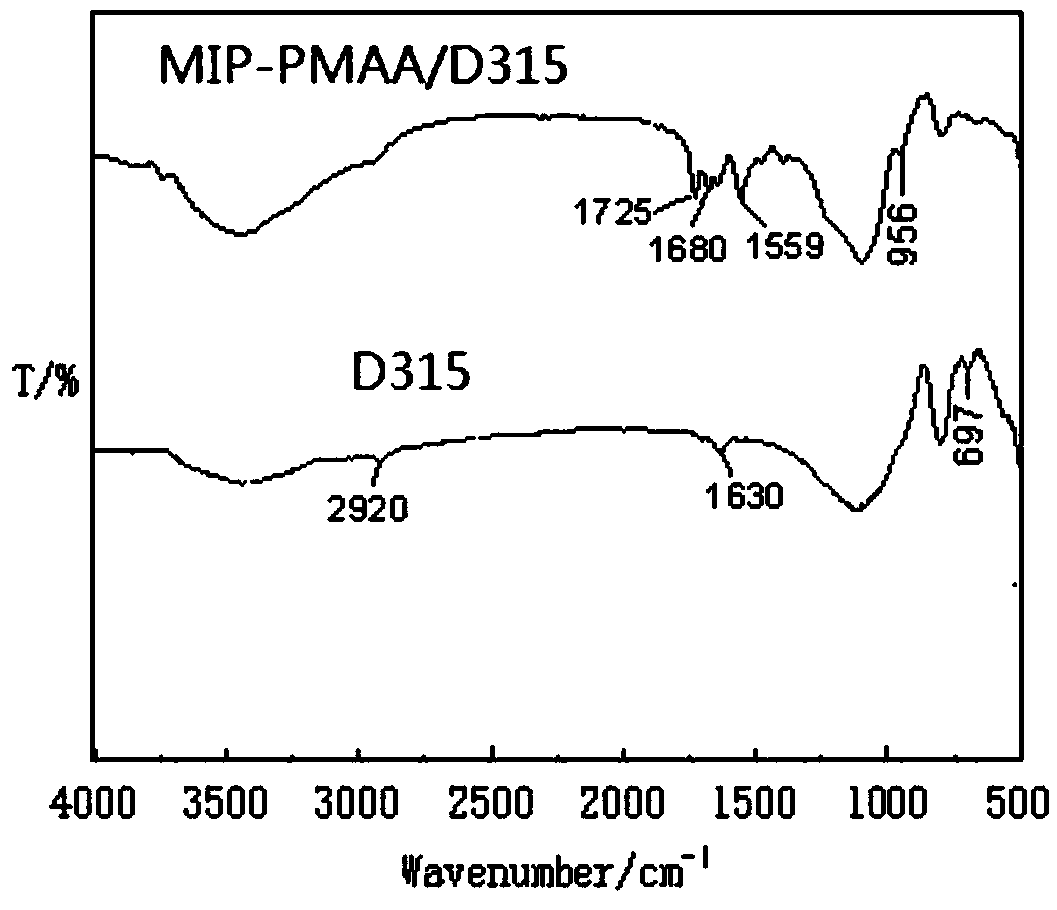

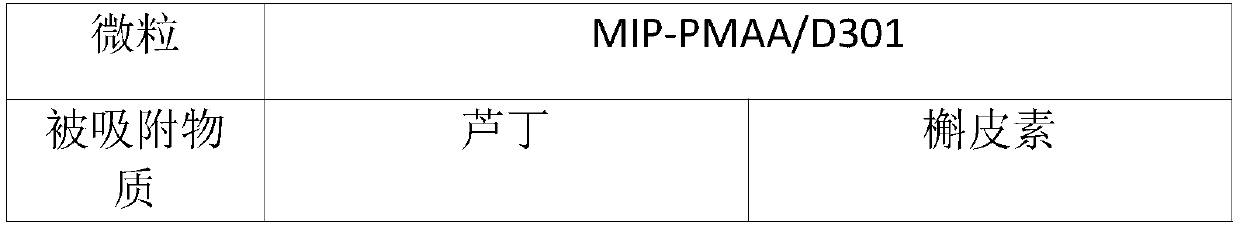

[0023] Add 90mL of N,N-dimethylformamide, 7.160g of rutin template molecules and 10mL of methacrylic acid MAA into a four-necked flask equipped with a reflux condenser, turn on the magnetic stirrer and stir for 10min, then add 1g of D315 Macroporous resin and 1.842g N,N-methylenebisacrylamide MBA, sealed, kept stirring and blowing nitrogen for 5 minutes, then raised the temperature of the constant temperature water bath to 30°C, added 0.098g ammonium persulfate to the reaction system, and The graft polymerization and crosslinking reaction were carried out under the condition of a constant temperature water bath of 30° C. and continuous stirring for 12 hours.

[0024] The reason why we choose D315 macroporous resin is that during the crosslinking reaction of this macroporous resin, under the action of the amino-ammonium persulfate surface initiation system, the monomer methacrylic acid MAA can be inserted into the surface of the macroporous resin. .

[0025...

Embodiment 2

[0028] step one:

[0029] Add 50mL of N,N-dimethylformamide, 5g of rutin template molecules and 5mL of methacrylic acid MAA into a four-neck flask equipped with a reflux condenser, turn on the magnetic stirrer and stir for 5 minutes, then add 1g of D941 Macroporous resin and 1g N, N-methylenebisacrylamide MBA, sealed, kept stirring and blowing nitrogen for 5min, then raised the temperature of the constant temperature water bath to 50°C, added 0.05g of ammonium persulfate to the reaction system, and kept stirring in the constant temperature water bath The graft polymerization and crosslinking reaction were carried out under the condition of 50° C. and continuous stirring for 10 h.

[0030] The reason why we choose D941 macroporous resin is that during the crosslinking reaction of this macroporous resin, under the action of the amino-ammonium persulfate surface initiation system, the monomer methacrylic acid MAA can be inserted into the surface of the macroporous resin .

[00...

Embodiment 3

[0034] step one:

[0035] Add 100mL of N,N-dimethylformamide, 10g of rutin template molecules and 15mL of methacrylic acid MAA into a four-necked flask equipped with a reflux condenser, turn on the magnetic stirrer and stir for 8 minutes, then add 3g of D315 Porous resin and 3g N,N-methylenebisacrylamide MBA, sealed, kept stirring and blowing nitrogen for 5min, then raised the temperature of the constant temperature water bath to 40°C, added 0.2g of ammonium persulfate to the reaction system, and kept stirring in the constant temperature water bath for 40 The graft polymerization and cross-linking reaction were carried out under the condition of continuous stirring at ℃ for 15 hours.

[0036] The reason why we choose D315 macroporous resin is that during the crosslinking reaction of this macroporous resin, under the action of the amino-ammonium persulfate surface initiation system, the monomer methacrylic acid MAA can be inserted into the surface of the macroporous resin. . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com