A sensor offset calibration method

A calibration method and sensor technology, applied in force/torque/power measuring instrument calibration/testing, instruments, measuring devices, etc., can solve the problems of ADC input full bias, normal quantization, operational amplifier distortion, etc., to achieve reduction Small offset voltage, reduce the difficulty of system design, and eliminate the effect of offset voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

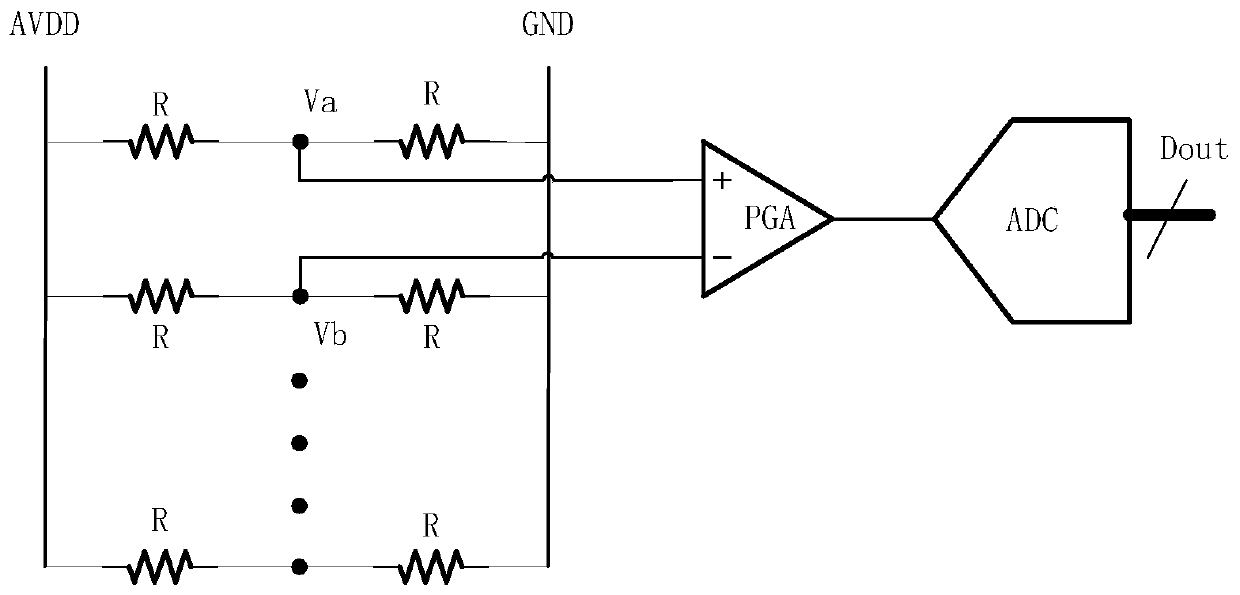

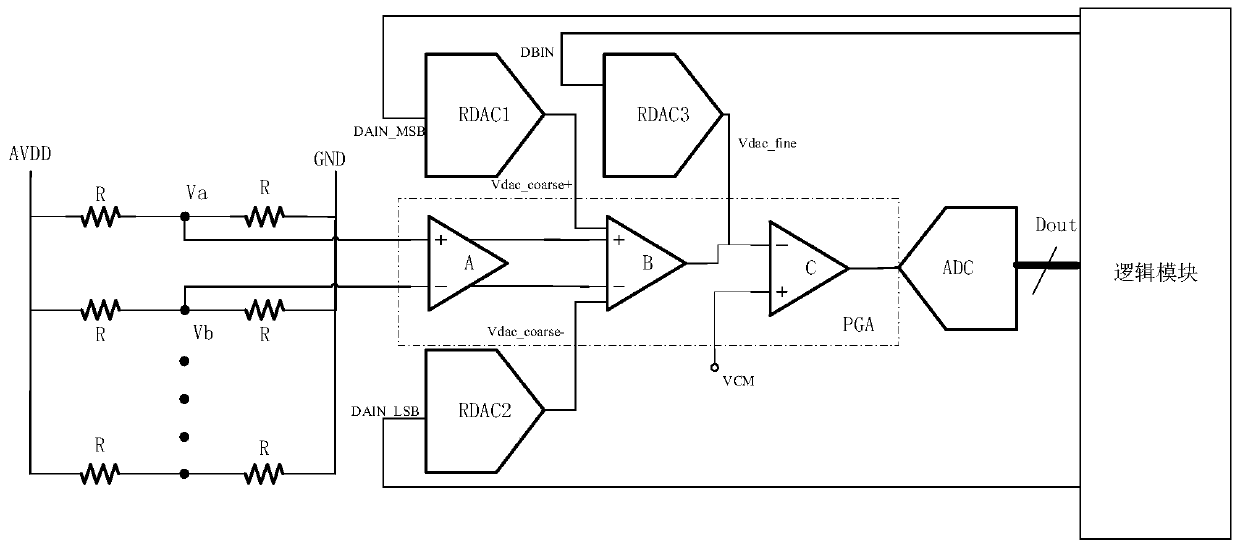

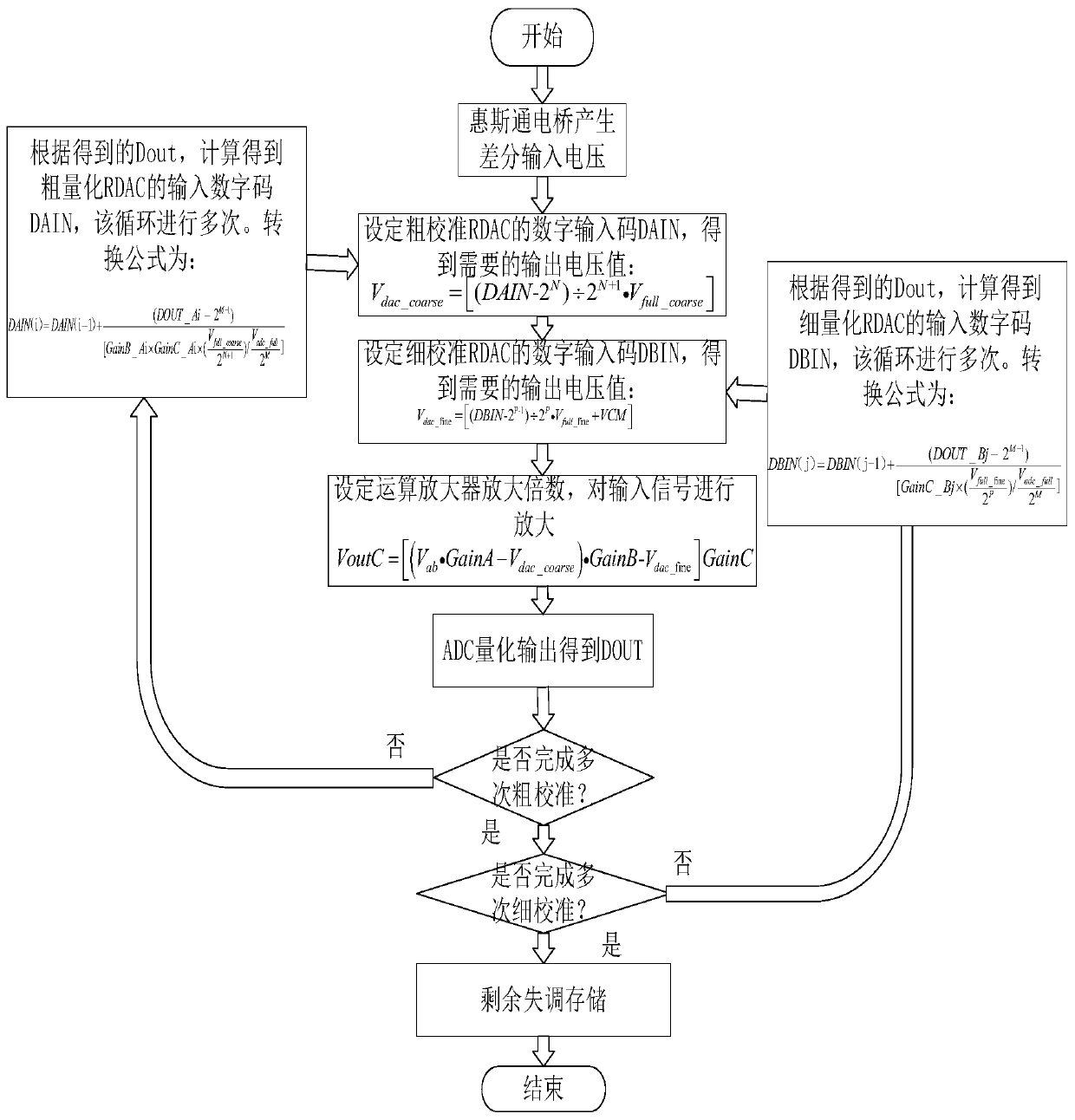

[0050] The offset calibration method proposed by the present invention is based on a calibration system, such as figure 2 Shown is a schematic structural diagram of the calibration system, including a digital-to-analog converter DAC and logic modules, and a three-stage programmable gain operational amplifier PGA that cooperates with the analog-to-digital converter ADC. The three-stage programmable gain operational amplifier PGA includes three cascaded operational amplifiers with programmable gain, which are the first operational amplifier A, the second operational amplifier B, and the third operational amplifier C. The corresponding gains of the three operational amplifiers are respectively are GainA, GainB and GainC, wherein the first operational amplifier A has a differential input and differential output struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com