A process and device for effectively improving the production efficiency of 4-chloro-3,5-dimethylphenol chlorination reaction

The technology of dimethylphenol and chlorination reaction is applied in the field of chlorination reaction of 4-chloro-3,5-dimethylphenol, which can solve the problems of unsolved catalyst recovery, serious side reactions, long cycle and the like, To achieve the effect of reducing the production of side reactions, increasing side reactions, and reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

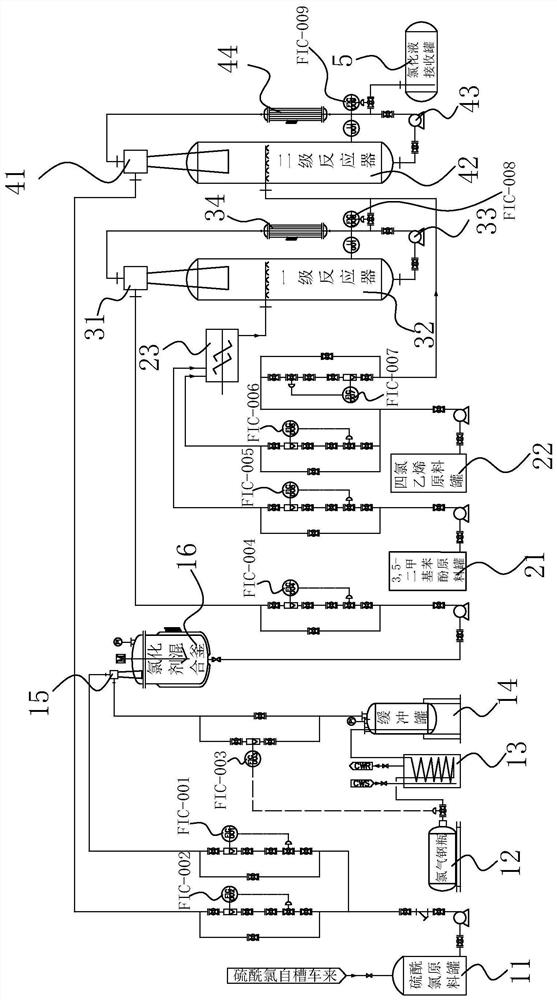

[0029] The invention provides a process that can effectively improve the production efficiency of the chlorination reaction of 4-chloro-3,5-dimethylphenol. The process mainly includes three processes, which are jet absorption process, primary reaction process and secondary process. level reaction process. figure 1 Schematically shows a device for 4-chloro-3,5-dimethylphenol chlorination production efficiency that can effectively improve production efficiency according to an embodiment of the present invention. Such as figure 1 As shown, the device opposite to the process includes a jet absorption unit, a raw material mixing unit, a primary reaction unit and a secondary reaction unit.

[0030] The spray absorption unit comprises a sulfuryl chloride raw material tank 11 storing liquid sulfuryl chloride, a chlorine cylinder 12 storing chlorine, a chlorine sparger 15 and a chlorinating agent mixing tank 16. The chlorine injector 15 is communicated with the sulfuryl chloride raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com