A method for simultaneously degrading biomass and photodegrading water to produce hydrogen

A biomass and light-induced technology, applied in chemical instruments and methods, hydrogen production, light water/sewage treatment, etc., to achieve high hydrogen production efficiency, good system stability, pollution-free degradation and comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

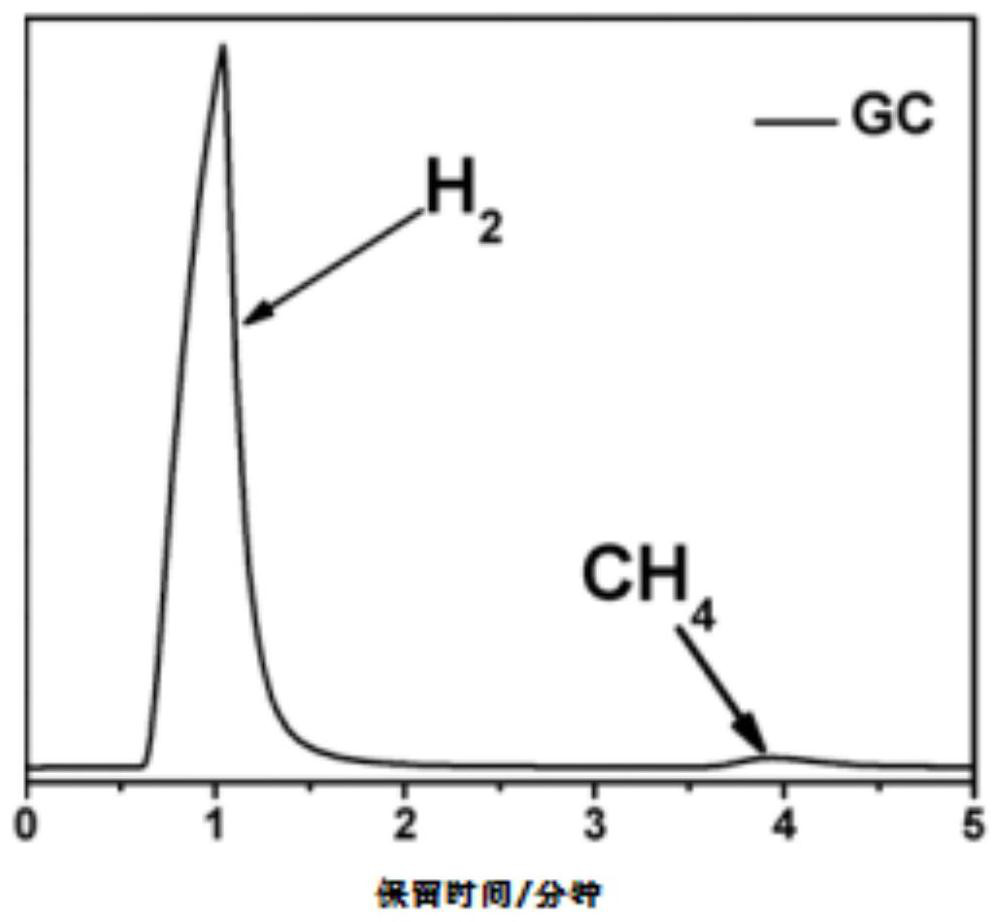

[0021] Add 10mL of MPA-CdSe QDs with an average particle size of 4nm, 1mg of cobalt dichloride, and 178mg of 3-aminopropionic acid into the pyrex test tube, mix well, and adjust the pH of the system to 11 with 0.1mol / L NaOH solution. In the system, 3- The concentration of aminopropionic acid is 0.2mol / L, the concentration of cadmium ion is 2.5×10 -4 mol / L, the concentration of cobalt dichloride is 4.2×10 -4 mol / L; make the system in a sealed nitrogen atmosphere, inject 500 μL of methane as an internal standard, and use a 420nm LED lamp to irradiate for 6 hours, and monitor the hydrogen produced by the gas chromatography system (such as figure 1 shown). Due to some errors in the quantification of gas chromatography, the hydrogen gas produced was quantified by the drainage method, and the results showed that the rate of hydrogen gas generation in this system reached 68 μmol h -1 ·mg -1 , 3-aminopropionic acid degradation rate of 83%.

Embodiment 2

[0023] In this example, the MPA-CdSe QDs in Example 1 were replaced with equimolar MUA-CdSe QDs, and other steps were the same as in Example 1.

Embodiment 3

[0025] In this example, the 3-aminopropionic acid in Example 1 was replaced with an equimolar amount of 4-aminobutyric acid, and other steps were the same as in Example 1. The system can generate hydrogen at a rate of 102 μmol h -1 ·mg -1 , 4-aminobutyric acid degradation rate as high as 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com