Full-automatic woven bag production line and process

A woven bag, fully automatic technology, applied in the field of woven bag packaging, can solve problems such as low packaging work efficiency, and achieve the effect of improving stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

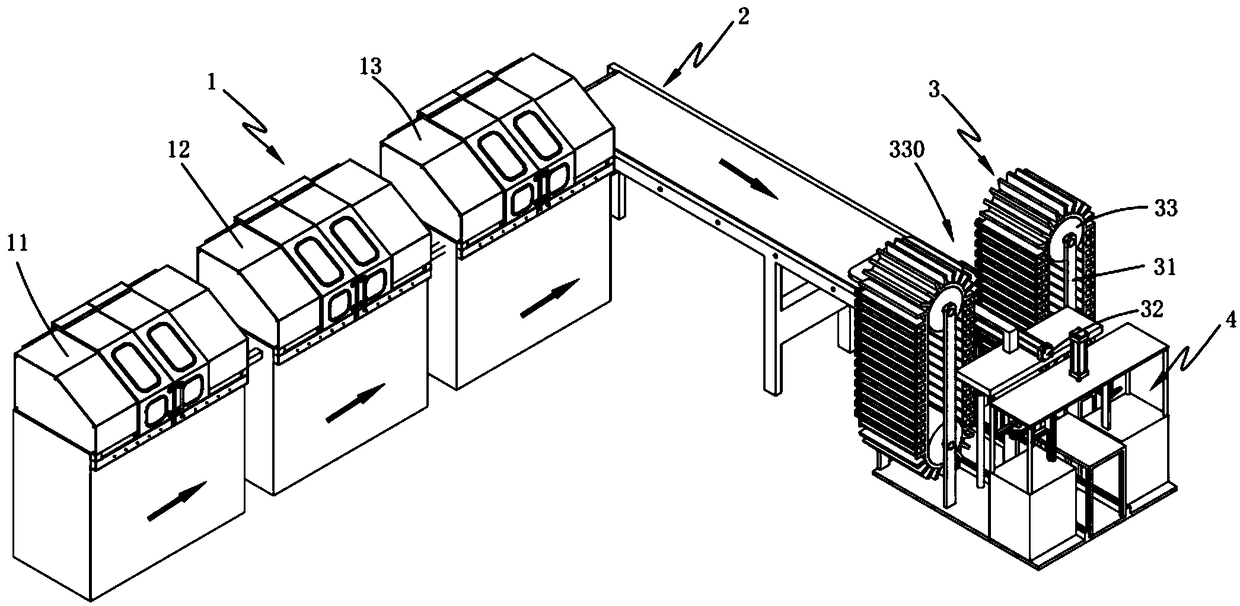

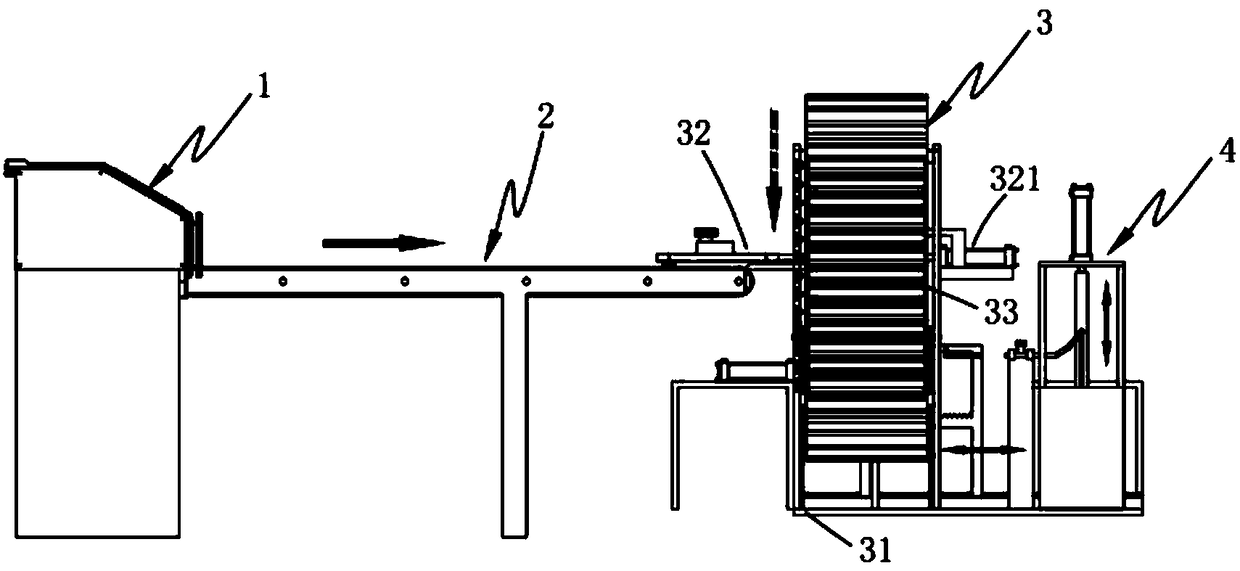

[0086] Such as Figure 1-14 As shown, a fully automatic production line for woven bags includes a woven bag forming mechanism 1 and a woven bag conveying mechanism 2 arranged on one side of the forming output end of the woven bag forming mechanism 1, and also includes:

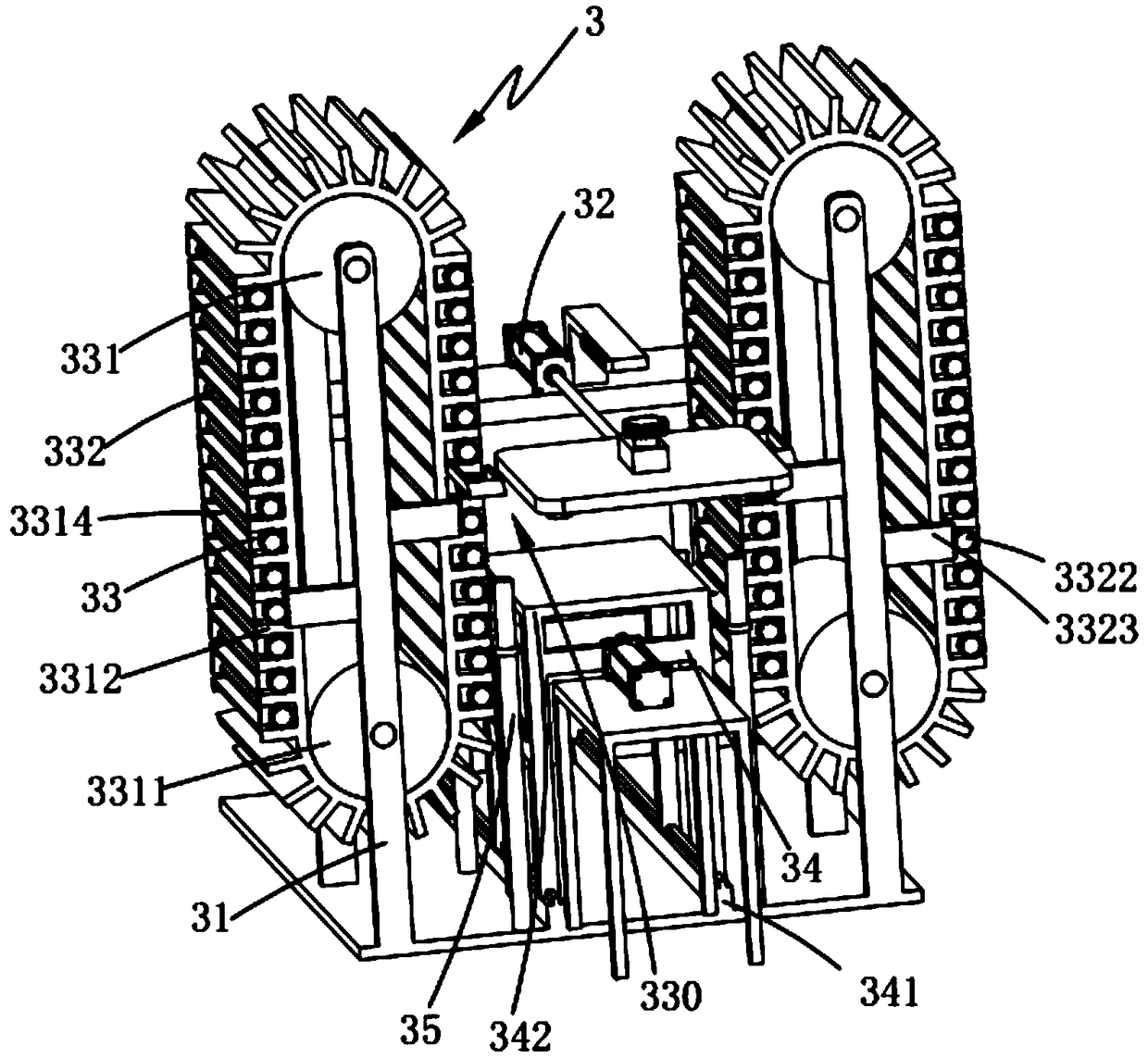

[0087] A woven bag stacking mechanism 3, the woven bag stacking mechanism 3 is arranged on one side of the output end of the woven bag conveying mechanism 2, and the woven bag stacking mechanism 3 includes a frame 31, an adsorption transportation assembly 32, and...

Embodiment 2

[0131] Figure 15 It is a structural schematic diagram of Embodiment 2 of a fully automatic production line for woven bags of the present invention; Figure 15 As shown, the parts that are the same as or corresponding to the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0132] Further, the finished product receiving assembly 43 includes:

[0133] Finished product receiving platform 431, said finished product receiving platform 431 is fixedly arranged directly below said packaging area 4220, and finished product receiving area 4310 is formed above the finished product receiving platform 431;

[0134] The finished product output block 432 , the finished product output block 432 is fixedly arranged on the woven bag storage platform 342 , and the finished product out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com