Welding installation process of rotor partition plates of rotary air preheater

An installation process and air preheater technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problem of difficulty in meeting the installation quality requirements of the rotary air preheater rotor, affecting the output and economic operation of the unit, and adjusting the accuracy of the sealing gap. Reduce the problems such as avoiding the belt deviation, improve the adjustment accuracy, improve the output and economic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

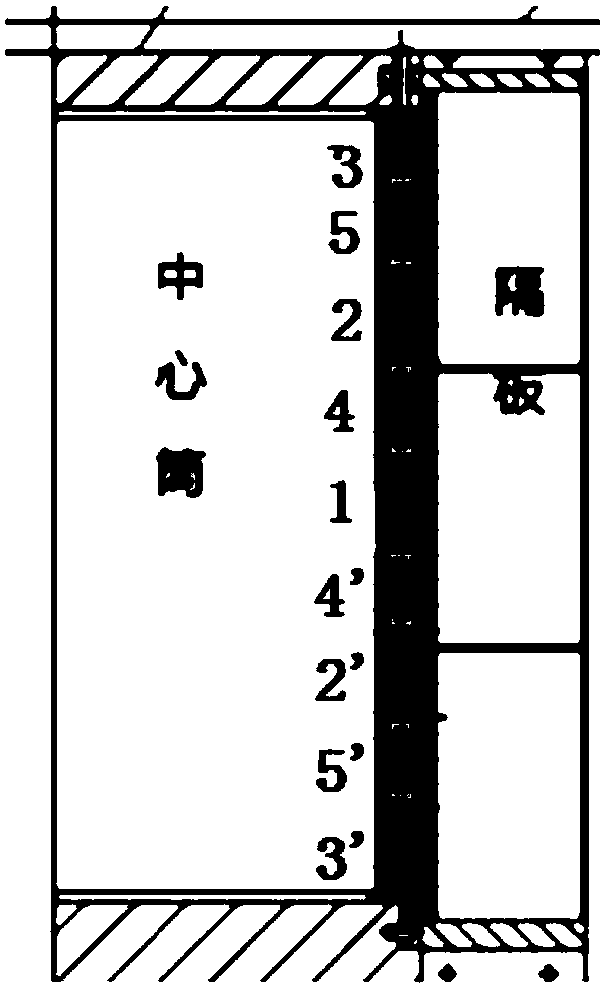

[0035] A welding and installation process for the rotor diaphragm of a rotary air preheater, including a central cylinder and six groups of diaphragms, each group of diaphragms includes four diaphragms, and the angle between two adjacent diaphragms of each group of diaphragms is 90°, such as figure 1 As shown, the welding of six sets of partitions includes the following steps:

[0036] (1) Preparation before welding: remove the rust, moisture and dirt within 20mm of the groove surface and both sides of the groove, and fully dry it, and prepare the arc striking plate and the arc extinguishing plate. Groove refers to the groove processed by the central cylinder and the partition on the part to be welded. The groove surface refers to the groove surface of the central cylinder and the partition. Cleaning the groove surface can reduce the occurrence of welding defects and improve the welding effect ;Prepare the arc striking plate and the arc extinguishing plate, which can avoid ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com