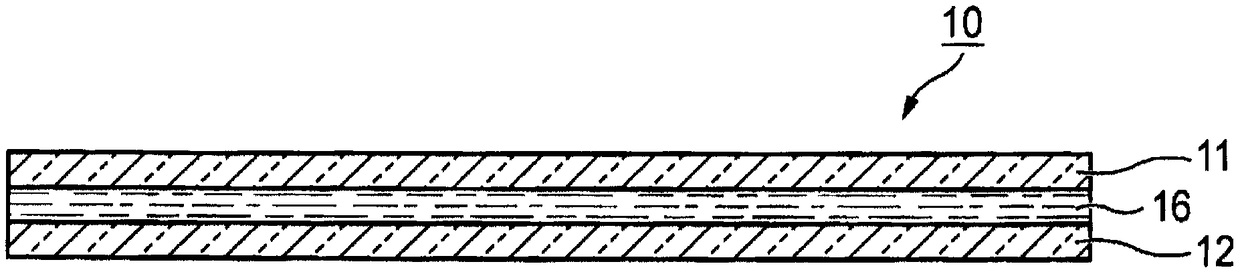

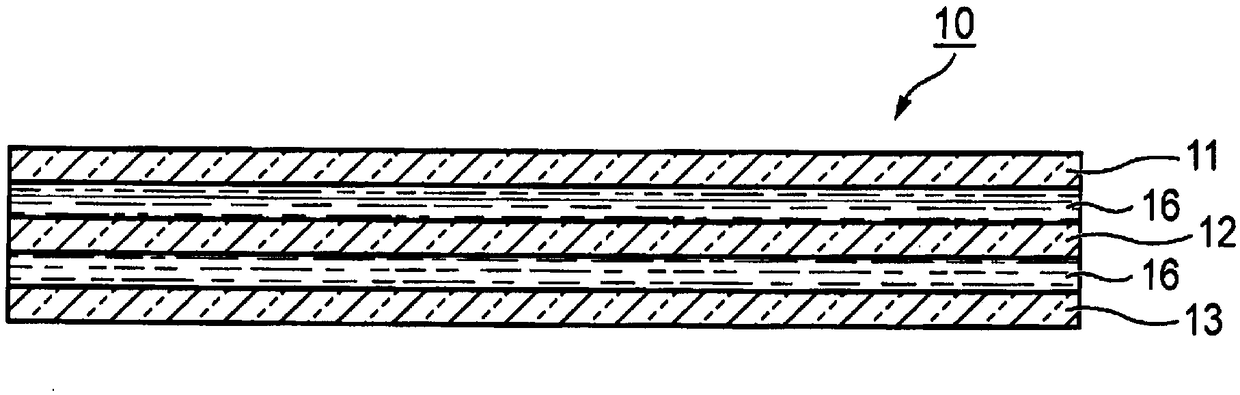

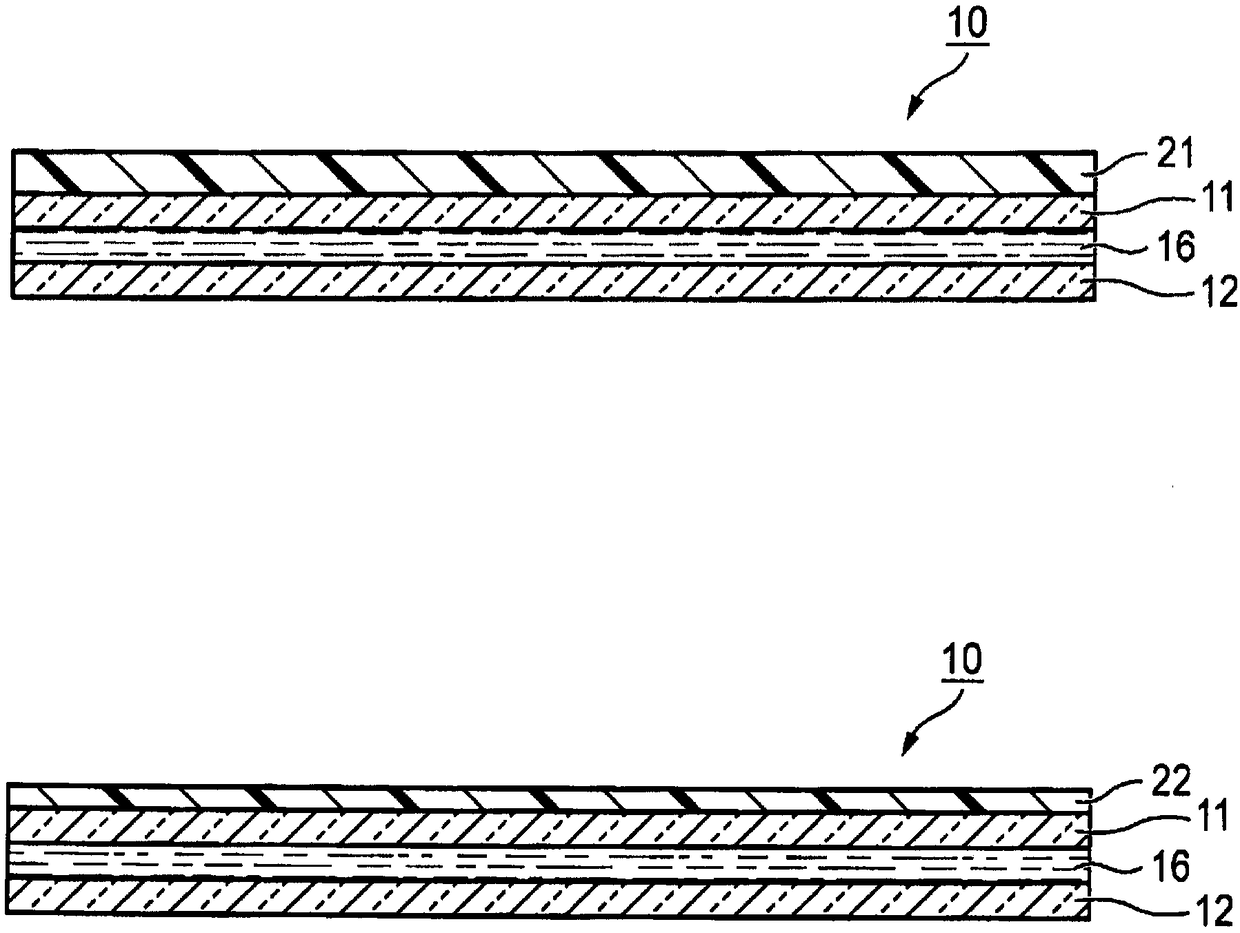

Glass plate constituent

A glass plate and structure technology, applied in glass/slag layered products, diaphragm structures, sound recording carriers, etc., can solve problems such as resonance mode, sound deterioration, residual reverberation sound, etc., to improve the damping effect, sound The reproducibility is good, and the effect of suppressing the generation of abnormal sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these Examples.

[0152]

[0153] (Young's modulus, longitudinal wave sound velocity value, density)

[0154]For the Young's modulus E and the sound velocity V of the glass plate, and the longitudinal wave sound velocity value V of the glass plate structure, use a test piece with a length of 60mm, a width of 12mm, and a thickness of 0.5mm to 1mm, and pass the Japanese Industrial Standard (JIS-R1602 -1995) by the ultrasonic pulse method described at 25° C. (DL35PLUS manufactured by Olympus Corporation was used). Regarding the longitudinal wave sound velocity value of the glass plate structure, the sound velocity in the plate thickness direction was measured.

[0155] The density (rho) of a glass plate was measured at 25 degreeC by the Archimedes method (Shimadzu Corporation, AUX320).

[0156] (Resonance frequency)

[0157] The loss factor of the ...

Embodiment 2~12

[0171] A glass plate structure was obtained in the same manner as in Example 1 except that the liquid layer was changed. In addition, in Example 6, instead of the glass plate 2 of the glass plate B, the glass plate 1 was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com