Paper cup, paper cup for acidic food

A paper cup and protective paper technology, which is applied in the field of paper cups and paper cups for acidic food, can solve the problems of multi-level stacking, buckling strength, transverse compressive strength, and high cost, etc., and achieves reduced weight per unit area and excellent mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

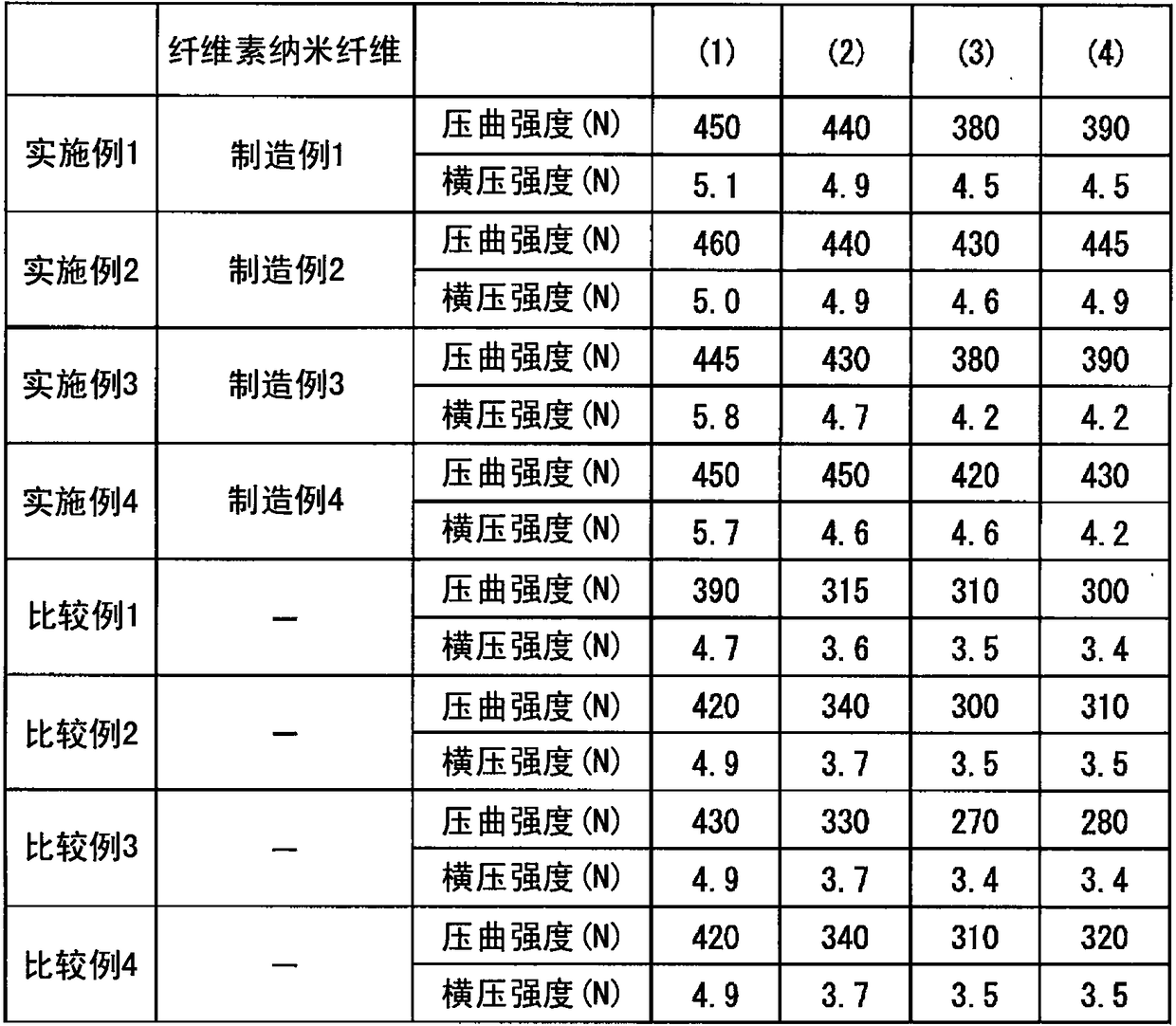

Examples

Embodiment approach

[0031] "paper cup"

[0032] figure 1 It is a perspective view which schematically shows the paper cup which concerns on 1st Embodiment of this invention.

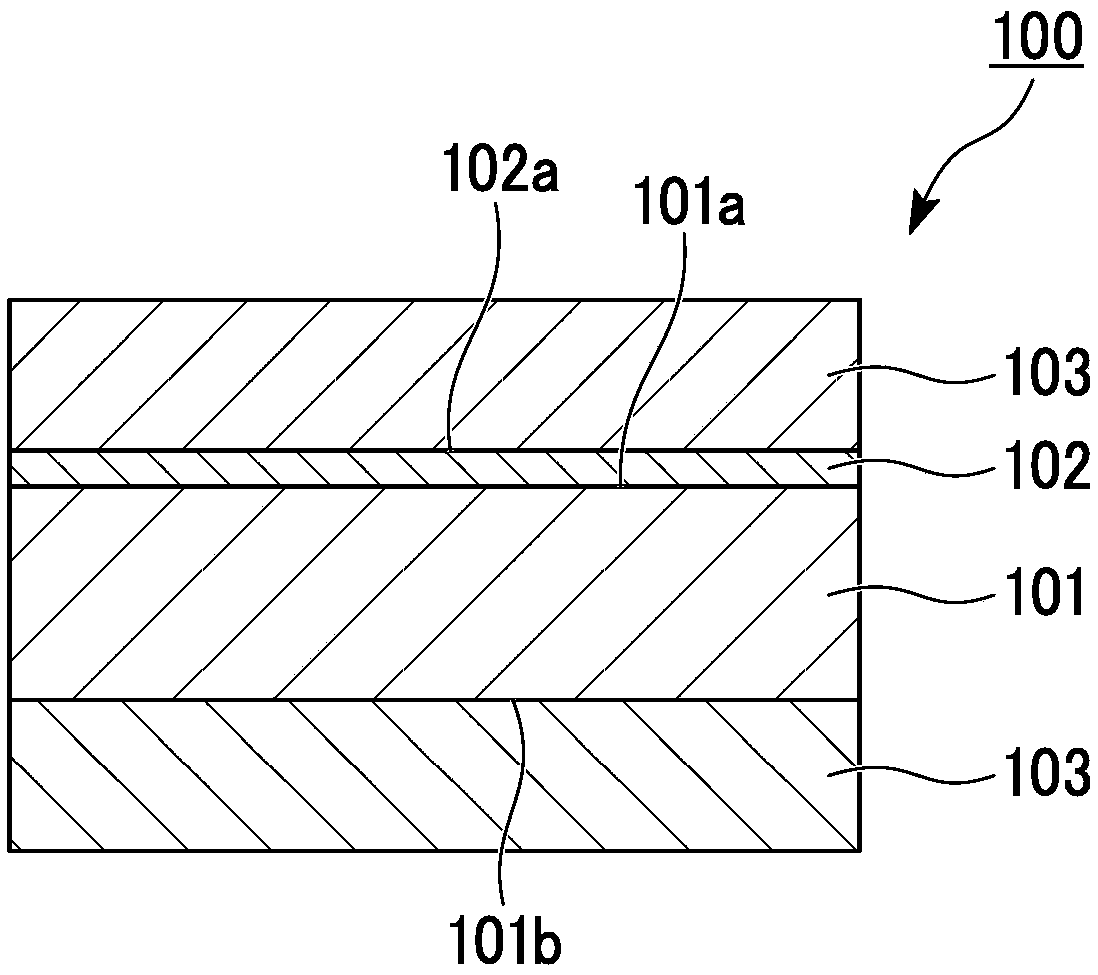

[0033] figure 2 It is a cross-sectional view schematically showing the protective paper constituting the paper cup according to the first embodiment of the present invention.

[0034] Such as figure 1 As shown in , the paper cup 10 according to this embodiment has a bottom 1 and a main body 2 .

[0035] The bottom 1 and the main body 2 are composed of figure 2 A protective paper 100 as shown in is formed. Protective paper 100 as figure 2 As shown in the paper base material 101, and formed on the paper base material 101, that is, one side of the paper base material 101 (hereinafter referred to as "the first side") 101a, the reinforcing layer comprising cellulose nanofibers 102.

[0036] In addition, protective paper 100 such as figure 2 As shown in , there is a sealing layer formed on the surface of the reinforc...

manufacture example 1

[0120] Water was added to 18 g of conifer kraft pulp to adjust to 1800 g, and this was treated with a rotary blade mixer for 30 seconds to disperse the conifer kraft pulp sparsely in water.

[0121] The conifer kraft pulp was left to stand for 3 days in a state dispersed in water to fully swell the conifer kraft pulp.

[0122] The swollen coniferous kraft pulp was processed 8 times with millstone E-#46 and 6 times with G-#80 using a stone mill (trade name: Super MasscolloiderMK CA6-2, manufactured by Masuko Sangyo Co., Ltd.) After treatment, a white milky dispersion of cellulose nanofibers was obtained.

manufacture example 2

[0124] 30 g of coniferous kraft pulp was immersed in 600 g of water, and treated with a rotary blade mixer for 30 seconds to disperse the coniferous kraft pulp sparsely in water.

[0125] 0.3 g of TEMPO and 3 g of NaBr dissolved in 200 g of water in advance were added to the dispersed pulp slurry, and further diluted with water to adjust the whole to 1400 mL.

[0126] The inside of the system was kept at 20° C., and an aqueous sodium hypochlorite solution was added dropwise to the diluted pulp slurry so as to become 10 mmol with respect to 1 g of cellulose.

[0127] The pH of the diluent began to drop from the dropwise addition, but the pH of the diluent was kept at 10 by adding dropwise a 0.5N aqueous sodium hydroxide solution at any time.

[0128] Four hours later, just as the dropwise amount of the 0.5N aqueous sodium hydroxide solution reached 2.8 mmol / g, 30 g of ethanol was added to the diluent to stop the reaction.

[0129] 0.5N hydrochloric acid was added to the diluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com