Motor shaft reduce mechanism

A deceleration mechanism and motor shaft technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of unstable motor operation, shortened motor service life, motor shaft failure, etc., achieve significant deceleration effect, eliminate inertial rotation, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

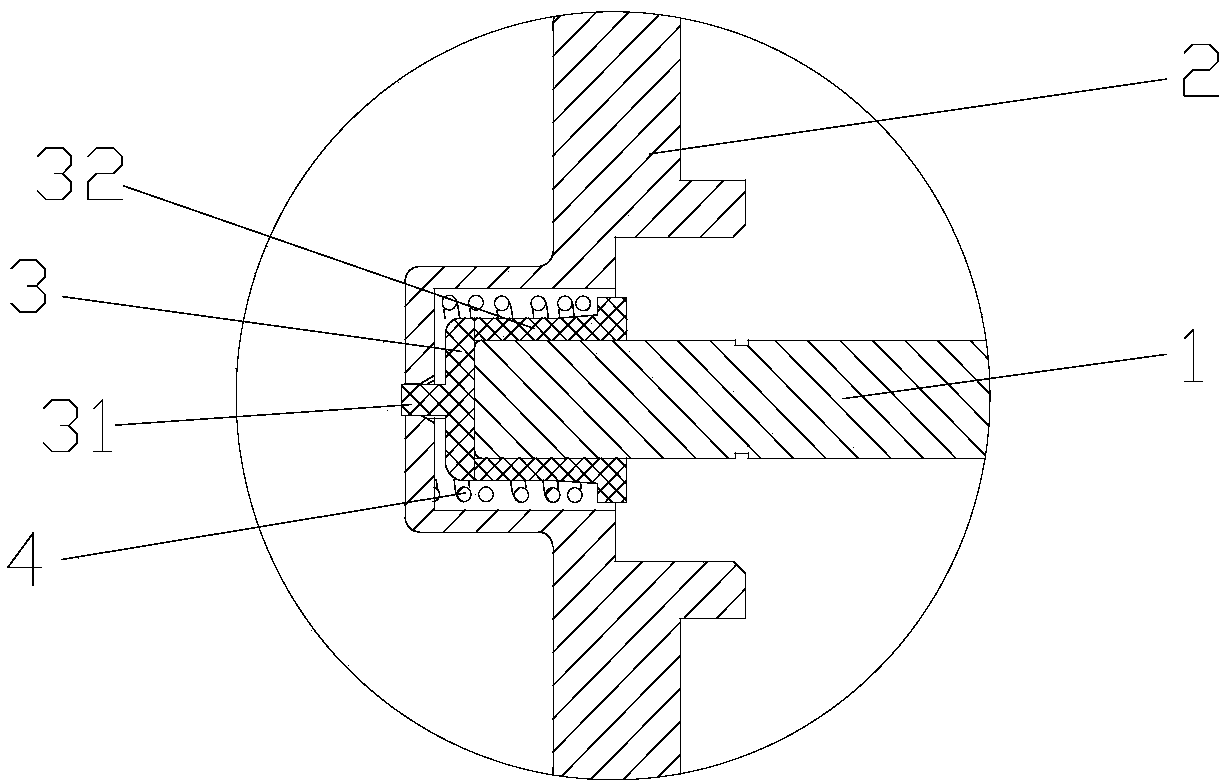

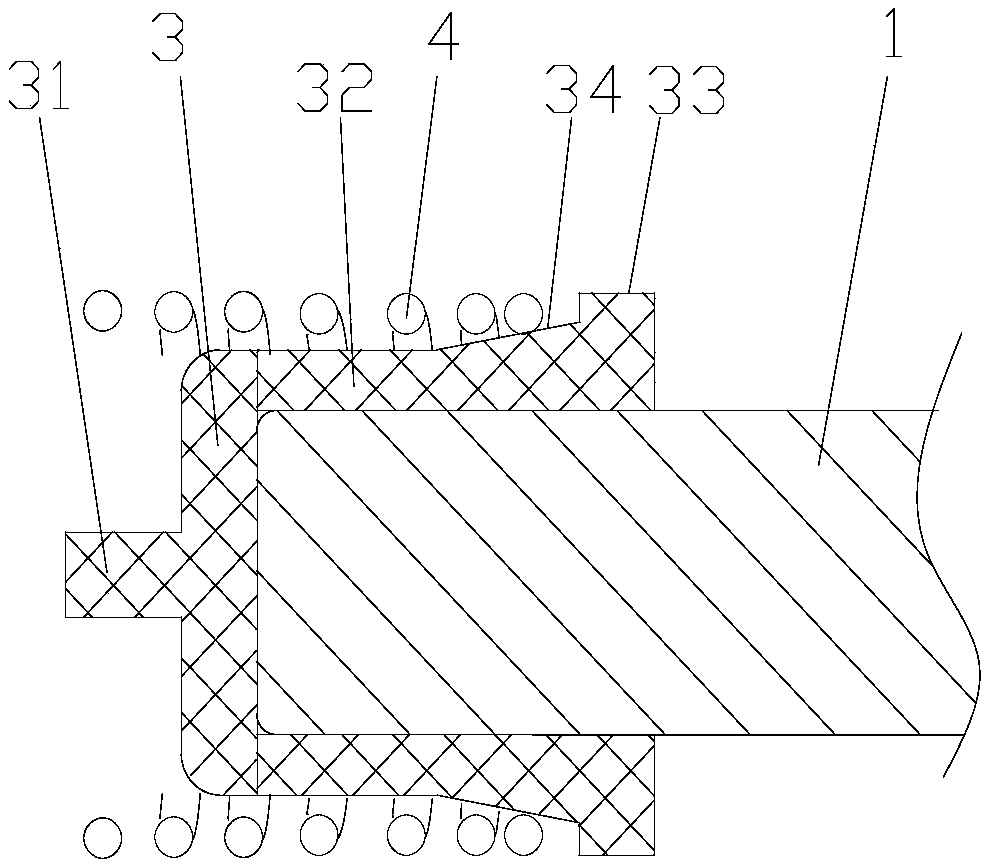

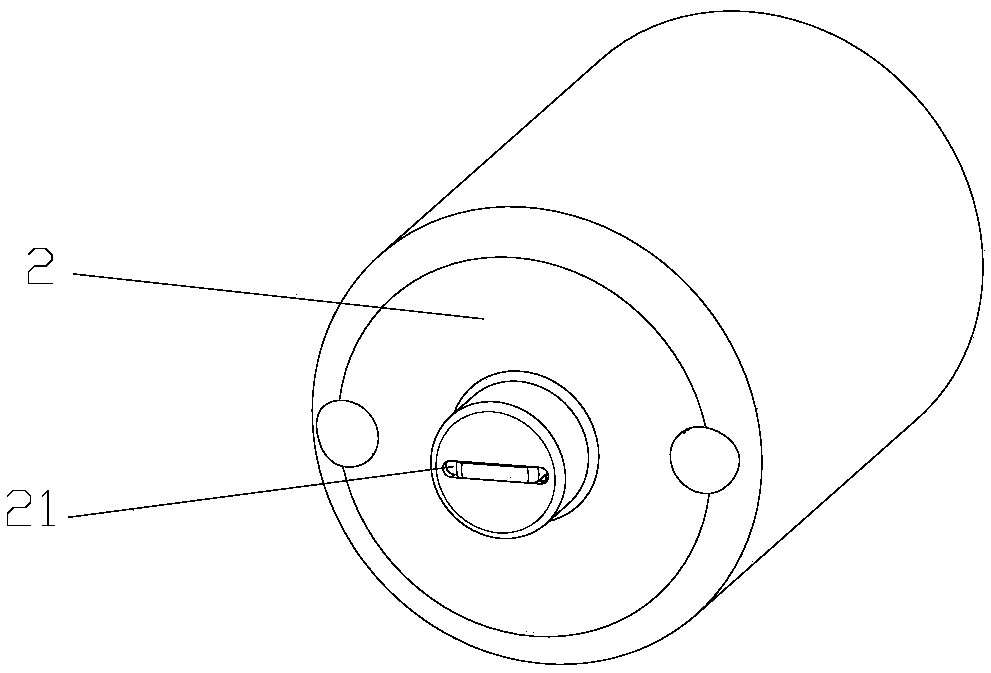

[0032] Embodiment 1: refer to Figure 1-Figure 3 , a motor shaft reduction mechanism, including a motor shaft 1, a motor rear end cover 2, a friction sleeve 3 in contact with the end surface of the motor shaft 1 is provided at the end of the motor shaft 1, and the friction sleeve 3 is made of a polymer wear-resistant material , the friction sleeve 3 is arranged at the end of the motor rear end cover 2 corresponding to the motor shaft 1, and the end surface of the friction sleeve 3 close to the motor rear end cover 2 is provided with a straight positioning protrusion 31 protruding toward the motor rear end cover 2, The corresponding position of the motor rear end cover 2 is provided with a positioning groove 21 that matches the positioning protrusion 31 and is consistent with the positioning protrusion 31. The positioning protrusion 31 snaps into the positioning groove 21 to realize the positioning of the motor rear end cover 2 to the friction sleeve 3 , to prevent the friction...

Embodiment 2

[0033] Embodiment 2: refer to figure 1 , Figure 4, a motor shaft reduction mechanism, including a motor shaft 1, a motor rear end cover 2, a friction sleeve 3 in contact with the end surface of the motor shaft 1 is provided at the end of the motor shaft 1, and the friction sleeve 3 is made of a polymer wear-resistant material , the friction sleeve 3 is arranged at the end of the motor rear end cover 2 corresponding to the motor shaft 1, and the end surface of the friction sleeve 3 close to the motor rear end cover 2 is provided with a straight positioning protrusion 31 protruding toward the motor rear end cover 2, The corresponding position of the motor rear end cover 2 is provided with a positioning groove 21 that matches the positioning protrusion 31 and is consistent with the positioning protrusion 31. The positioning protrusion 31 snaps into the positioning groove 21 to realize the positioning of the motor rear end cover 2 to the friction sleeve 3 , to prevent the fricti...

Embodiment 3

[0034] Embodiment 3: refer to figure 1 , a motor shaft reduction mechanism, including a motor shaft 1, a motor rear end cover 2, a friction sleeve 3 in contact with the end surface of the motor shaft 1 is provided at the end of the motor shaft 1, and the friction sleeve 3 is made of a polymer wear-resistant material , the friction sleeve 3 is arranged at the end of the motor rear end cover 2 corresponding to the motor shaft 1, and the end surface of the friction sleeve 3 close to the motor rear end cover 2 is provided with a straight positioning protrusion 31 protruding toward the motor rear end cover 2, The corresponding position of the motor rear end cover 2 is provided with a positioning groove 21 that matches the positioning protrusion 31 and is consistent with the positioning protrusion 31. The positioning protrusion 31 snaps into the positioning groove 21 to realize the positioning of the motor rear end cover 2 to the friction sleeve 3 , to prevent the friction sleeve 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com