Quality evaluation method of sorting equipment based on AHP and QFD

A quality assessment and equipment technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems that user requirements cannot be transformed into design requirements, and the influence of subjective experience cannot be avoided, and achieves strong operability and versatility. The effect of improving user satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] 1 Establishment of user demand system and determination of importance for automatic sorting equipment

[0045] 1.1 Analytic Hierarchy Process

[0046] Analytical Hierarchy Process (AHP) is a hierarchical weight decision-making analysis method that applies network system theory and multi-objective comprehensive evaluation method, combines qualitative and quantitative methods to solve multi-objective complex problems.

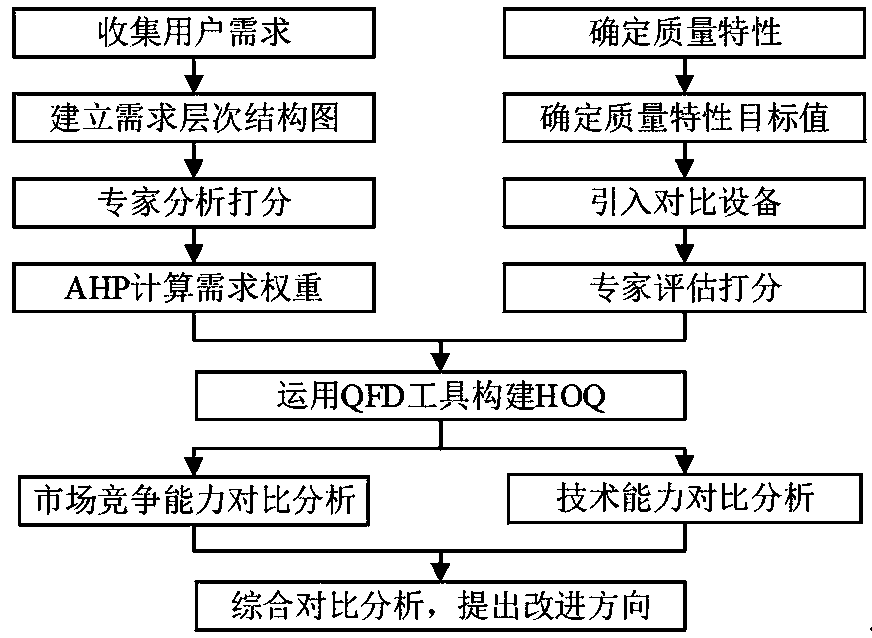

[0047] The specific analysis and evaluation process is as follows:

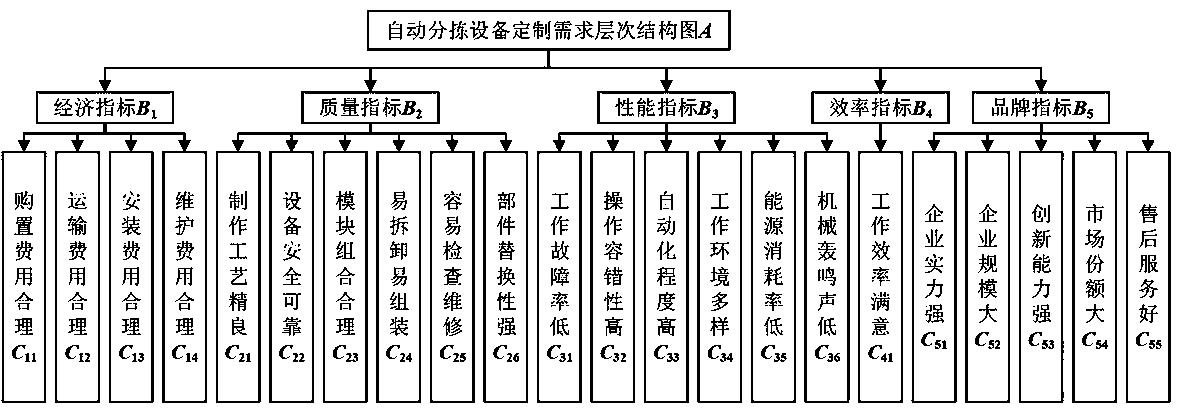

[0048] (1) Establish a hierarchical structure model of customized user needs for automatic sorting equipment, which is divided into the first layer A, the second layer B and the third layer C;

[0049] (2) Compare user requirements layer by layer, judge the relative importance of elements in each layer, and construct a judgment matrix X=(x ij ) n×n .

[0050] (3) Use the square root method to calculate the eigenvector W and the largest eigenvalue λ of the judgment matrix X max . The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com