Dynamic modeling method for combustion process of circulating fluidized bed boiler

A circulating fluidized bed and boiler combustion technology, which is applied in neural learning methods, design optimization/simulation, biological neural network models, etc. Information processing methods, real-time modeling, and adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

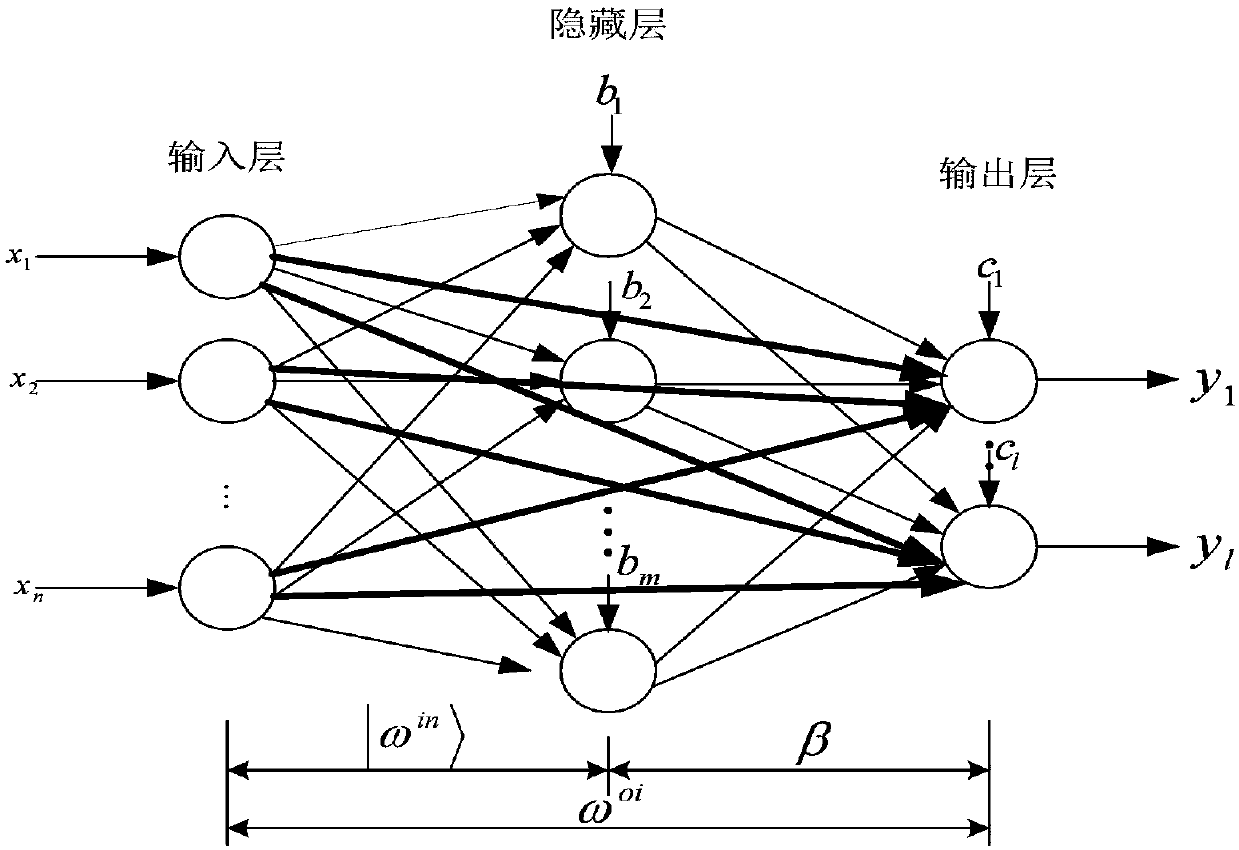

[0037] A kind of dynamic modeling method of circulating fluidized bed boiler combustion process of the present invention, its content comprises the following steps:

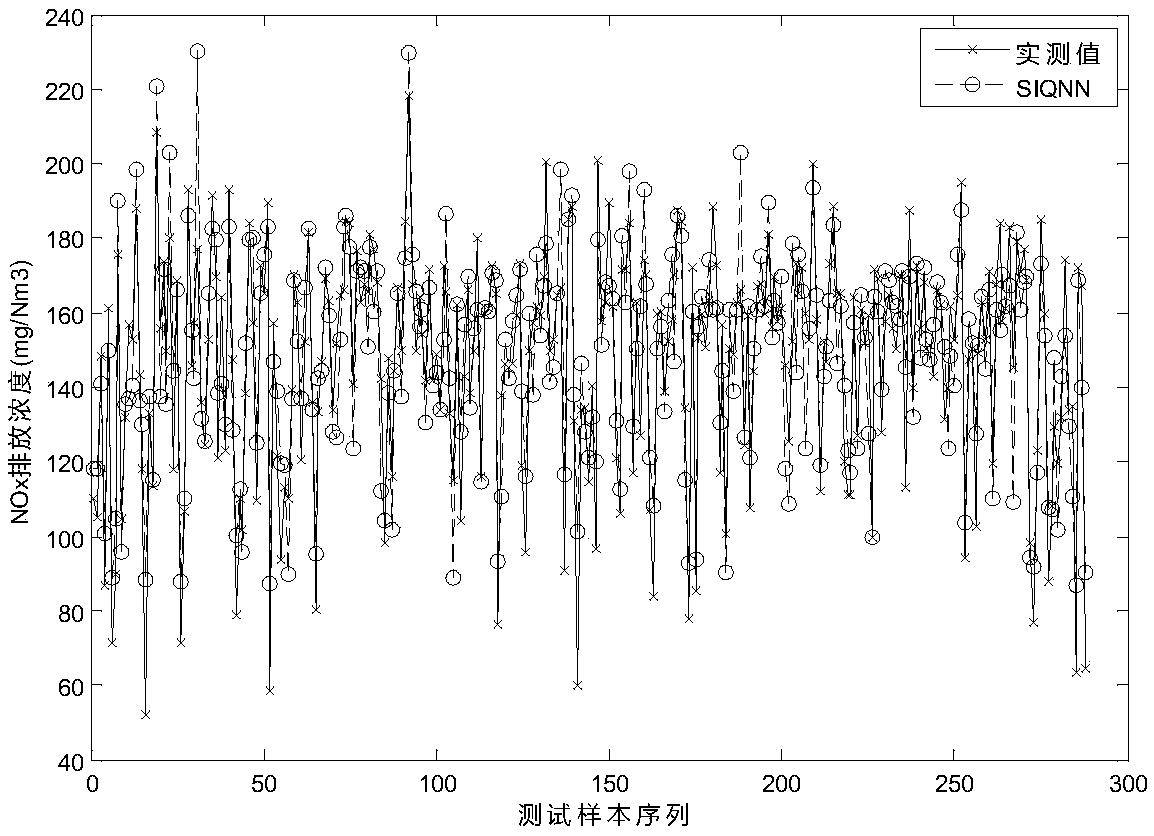

[0038] Step 1: Obtain the operating parameters of the boiler combustion process that mainly affect the boiler thermal efficiency and nitrogen oxide emission concentration, and record them as input data and output data.

[0039] In step 1, the input data includes: boiler load, coal feed rate, average bed temperature in the upper part of the furnace dense phase area, average bed temperature in the upper part of the left furnace dense phase area, average bed temperature in the upper part of the right furnace dense phase area, left Primary air flow at the burner inlet of the side air duct, primary air flow at the burner inlet of the right air duct, primary air temperature at the burner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com