Method used for stripping influence of background noise in sealed cabin noise testing process

A background noise and airtight chamber technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of analyzing background noise and affecting the accuracy of the actual measurement results, and achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

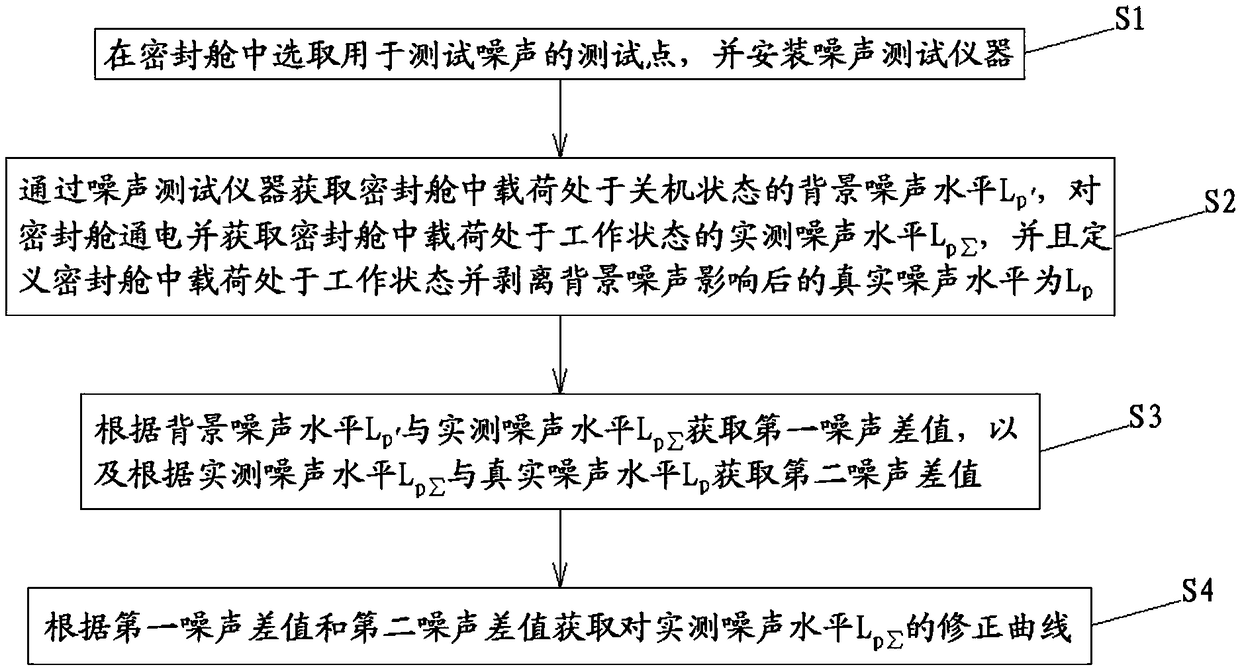

[0040] Such as figure 1 As shown, according to an embodiment of the present invention, a method for stripping the influence of background noise when testing the noise of the sealed cabin of the present invention includes:

[0041] S1. Select test points for testing noise in the airtight cabin, and install noise testing instruments;

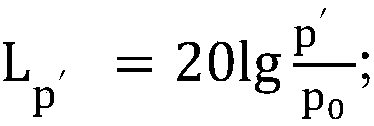

[0042] S2. Obtain the background noise level L of the load in the airtight cabin in the shutdown state through the noise testing instrument p' , energize the airtight cabin and obtain the measured noise level L of the load in the airtight cabin in working condition p∑ , and define the real noise level after the load in the airtight compartment is in working condition and the effect of background noise is removed as L p ;

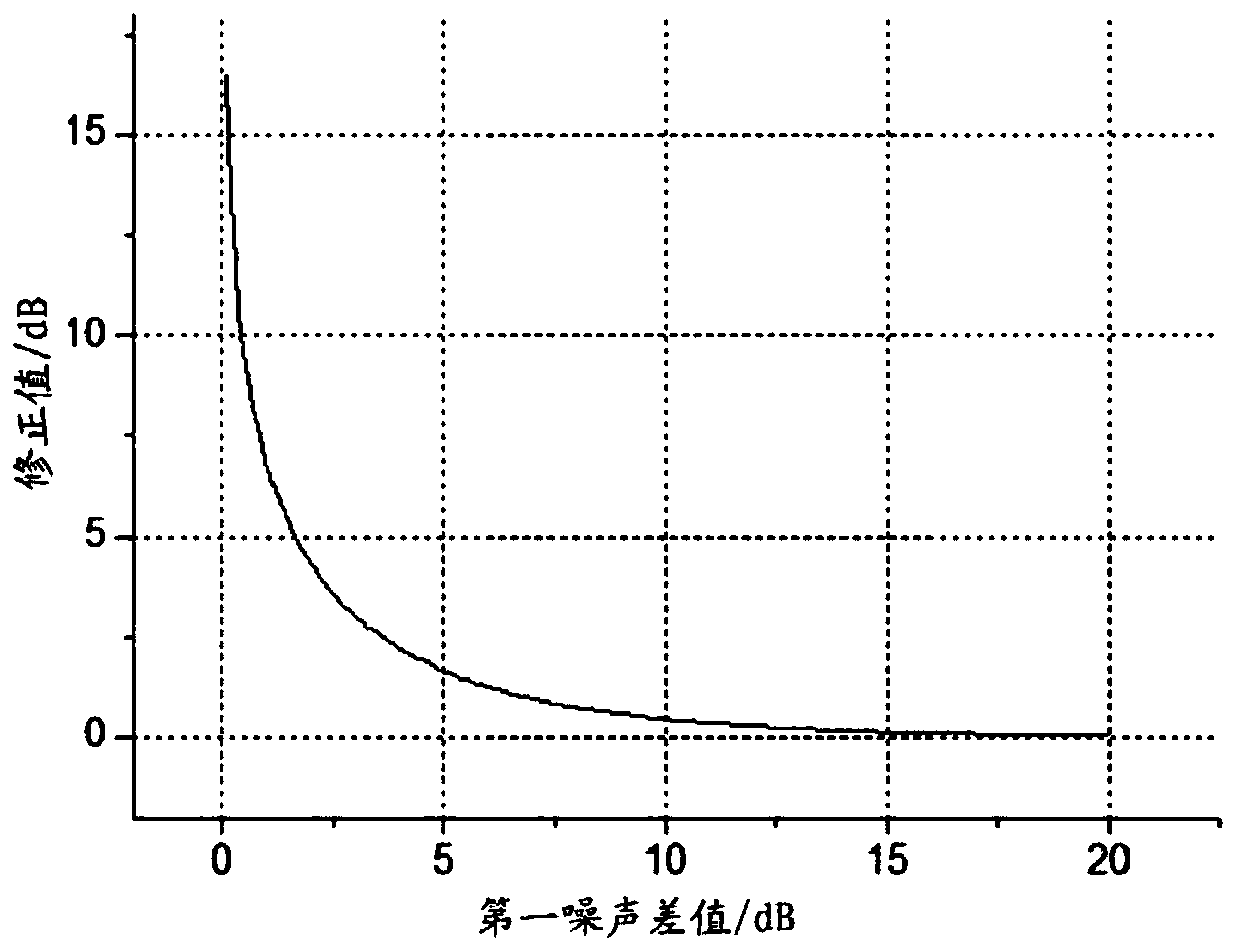

[0043] S3. According to the background noise level L p' with the measured noise level L p∑ Obtain the first noise difference, and according to the measured noise level L p∑ with the real noise level L p Obtain a second no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com