Powder engine with adjustable flame stabilizer position and method for installing flame stabilizer of powder engine

A technology of engine and flame stabilizer, which is applied in the direction of powdered engine fuel, machine/engine, combustion engine, etc. It can solve the problems that the position of the stabilizer cannot be adjusted freely, the refilling of closed fuel is inconvenient, and the consumption of materials, etc., to achieve practicality and Easy to adjust, simple structure, improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

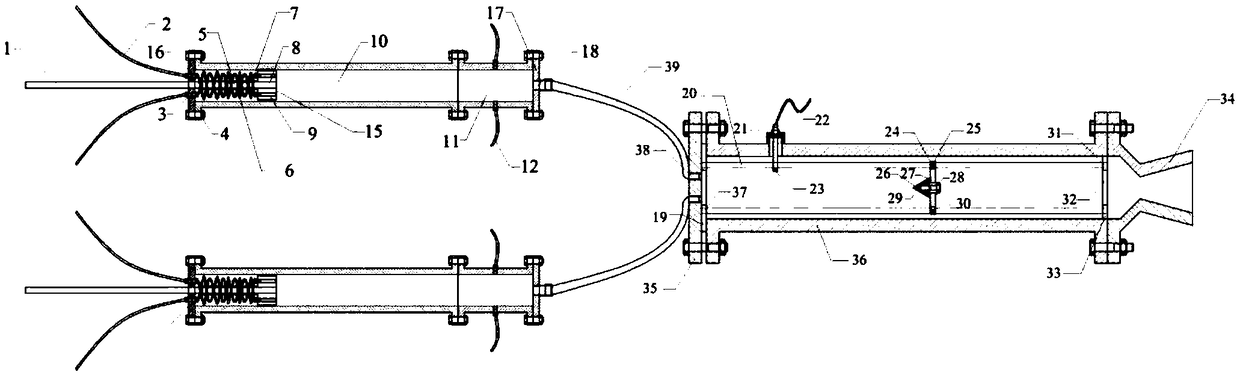

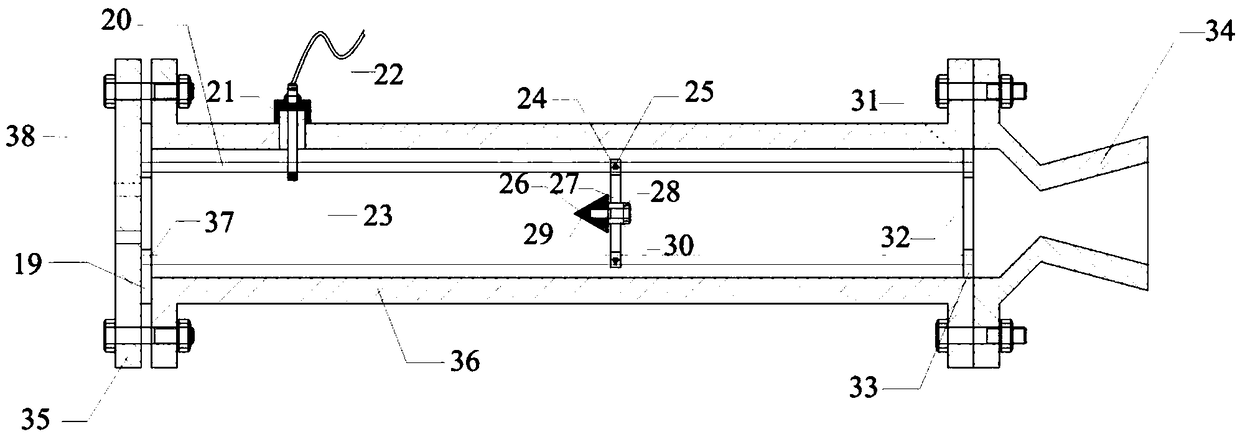

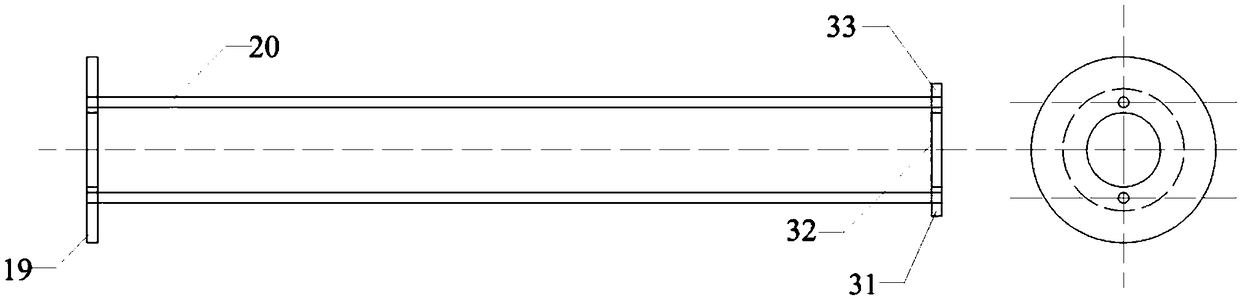

[0036] combine figure 1 , a powder engine with adjustable flame stabilizer position, said engine comprises a powder fuel supply device, a powder oxidant supply device, a combustion chamber 36 and a nozzle 34, and said powder fuel supply device and a powder oxidizer supply device are connected to the combustion chamber 36 The front end of the combustion chamber 36 is respectively connected with the front end of the combustion chamber 36 through the pipeline 39, and the rear end of the combustion chamber 36 is connected with the nozzle pipe 34, and the flame stabilizer 29 is arranged in the combustion chamber 36, and the flame stabilizer 29 is in the The axial position in the combustion chamber 36 can be adjusted.

[0037]Further, the combustion chamber 36 is fixed with M metal slide rails 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com