Hydraulic isolation support for coal mine paste filling mining

A paste filling and isolation support technology, applied in the direction of mine roof support, filling, mining equipment, etc., can solve the problems of low isolation and sealing efficiency, low efficiency, low degree of mechanization, etc., to reduce manual labor, ensure safety, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

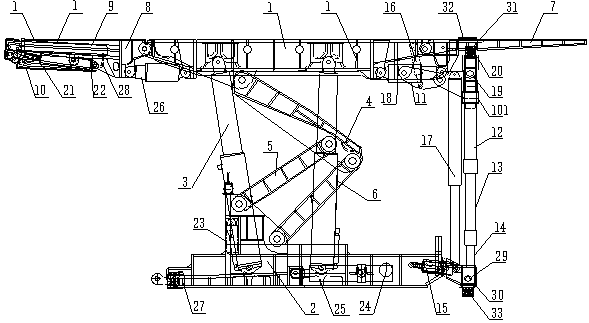

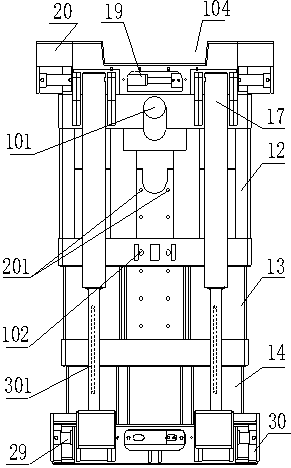

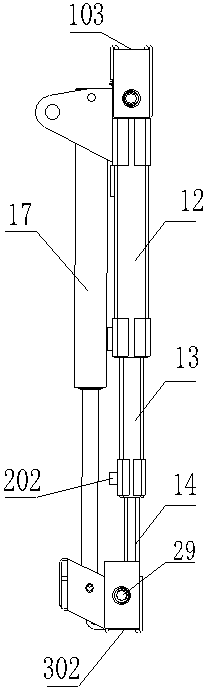

[0044] The hydraulic isolation support of the present invention includes: top beam 1, base 2, hydraulic support support column 3, inclined beam 4, front connecting rod 5, rear connecting rod 6, tail beam 7, front beam 8, telescopic beam 9, side protection Plate 10, Short Beam 11, Isolation Plate Tensioning Device 15, Isolation Plate Lifting Jack 16, Tail Beam Jack 18, Guard Jack 21, Telescopic Beam Jack 22, Bottom Lifting Jack 23, Bottom Adjustment Jack 24, Pushing Jack 25, Front Beam jack 26, pushing rod 27, supporting plate 28, upper isolation flexible strip 31, tail beam flexible strip 32, lower isolation flexible strip 33 and isolation device;

[0045] Between the top beam 1 and the base 2, there are 4 hydraulic support support columns 3 supporting the top beam, and the inclined beam 4, the front connecting rod 5 and the rear connecting rod 6 are hinged between the top beam 1 and the base 2;

[0046] The front beam 8 is hinged at the front end of the top beam 1, the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com