Construction method of a tower-type sliding support frame and a large-span semi-circular pipe truss structure

A truss structure and semi-circular tube technology, applied in building construction, building material processing, construction and other directions, can solve the problems of no economic and technical advantages, large influence of laying area, poor stability of frame body, etc. Standardized construction, shortened installation period, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

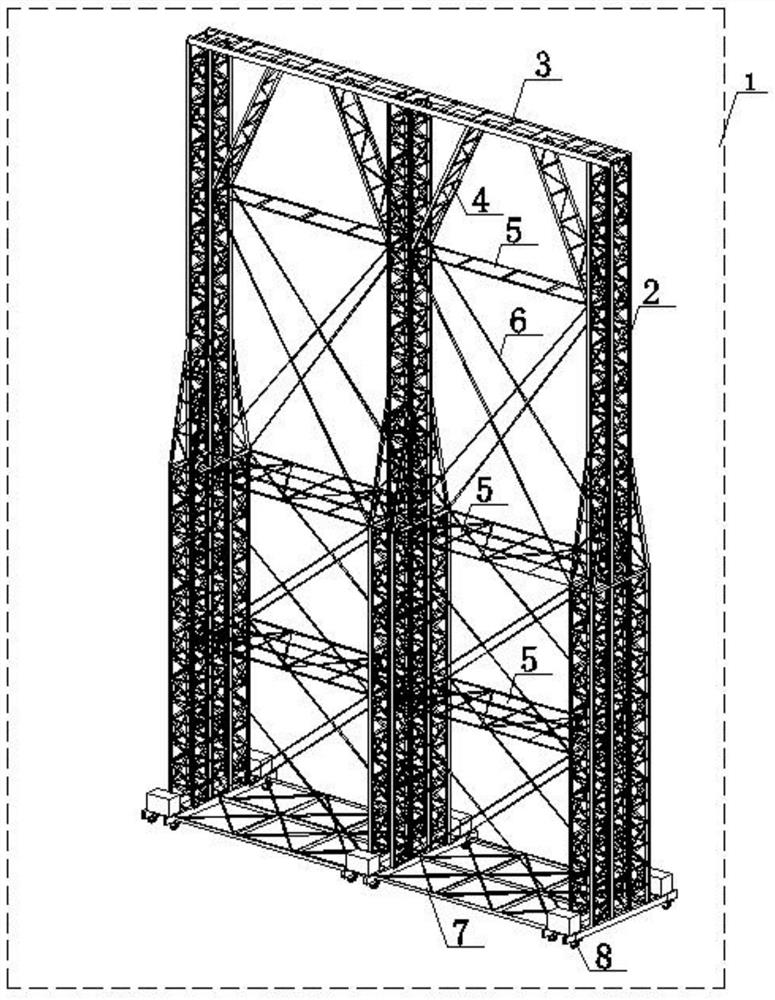

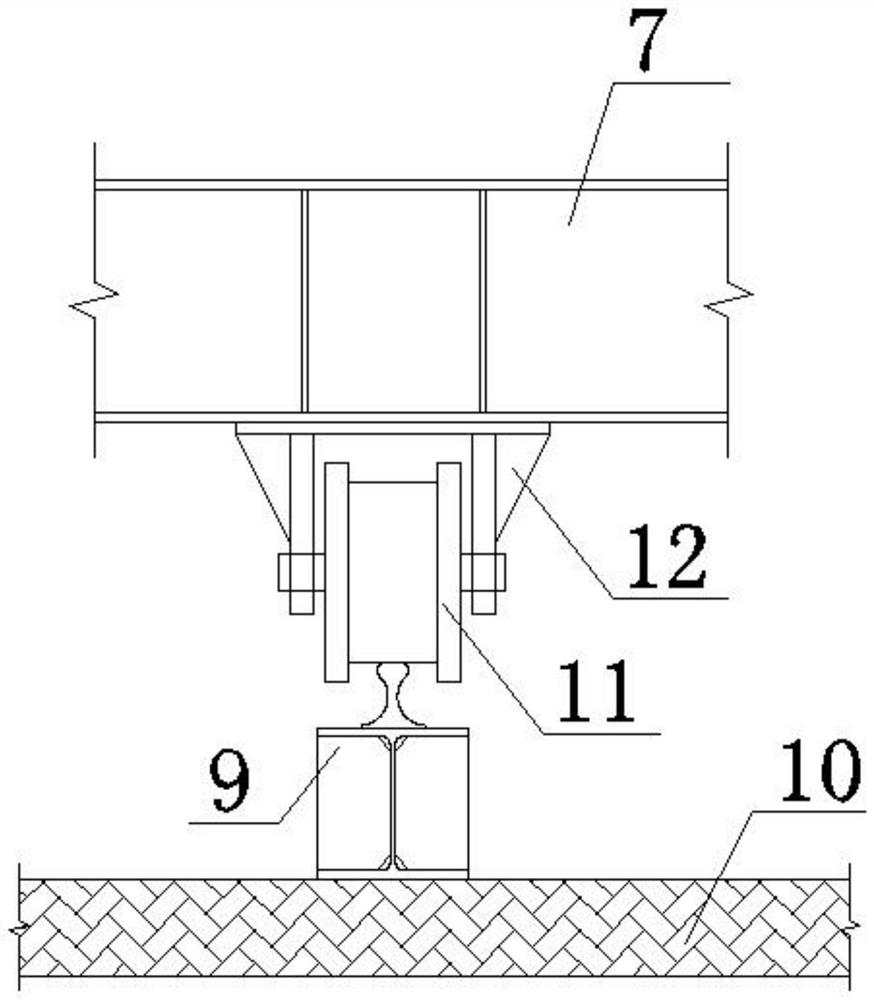

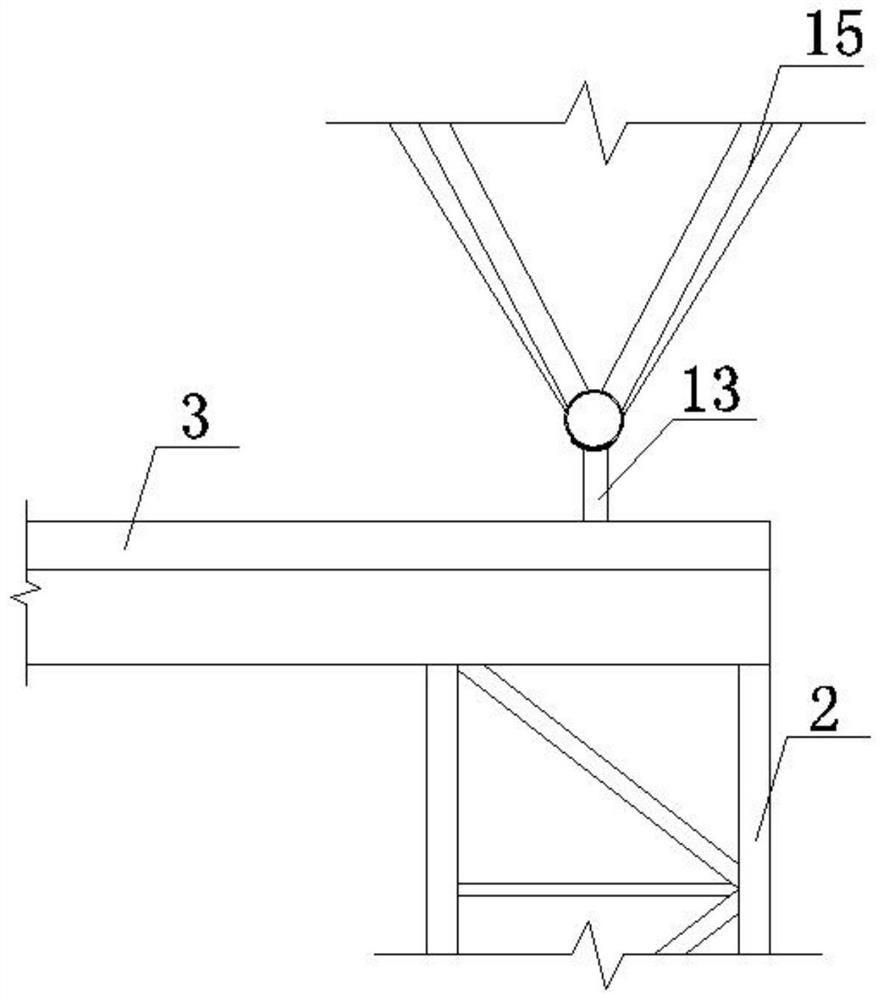

[0036] Such as Figure 1-10 As shown, what the present invention discloses is a construction method of a large-span semicircular pipe truss structure. During the construction process of the semicircular pipe truss structure 16, each main truss can be reasonably arranged according to the shape and force characteristics of the structure itself. It is divided into landing section 14 and middle section 15, and then the sliding track 9 is laid in the field, using the sliding construction technology of the tower sliding support frame 1, after several times of truss assembly, bracket sliding, and truss closing, until the half The circular tube truss structure 16 is fully integrated.

[0037] A tower type sliding support frame, specifically comprising:

[0038] 1), combined figure 1 As shown, the tower sliding support frame 1 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com