Self-stressing cable rod and rigid net shell combined structure and construction method thereof

A combined structure and self-stressing technology, applied in building components, building structures, roofs, etc., can solve the problems of long influence time, small out-of-plane rigidity of the structure, and large in-plane rigidity, etc., to achieve easy transportation and storage, and structural stability. The effect of good performance, large stiffness and span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

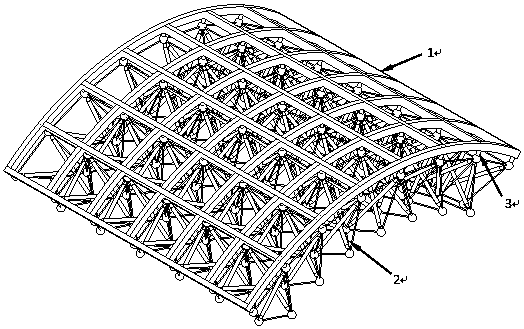

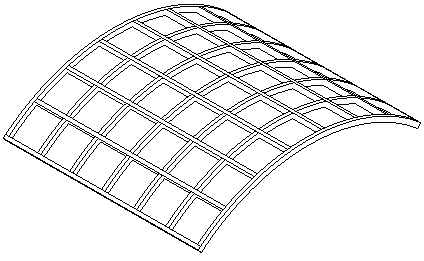

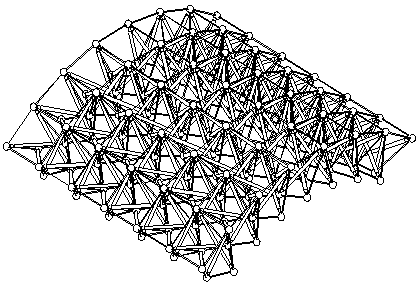

[0025] According to the present invention, a combined structure of self-stressing cable rod and rigid reticulated shell, such as figure 2 As shown; in this embodiment, the rigid reticulated shell 1 is formed by intersecting and welding orthogonal rectangular cross-section beams, such as image 3 As shown; the self-stressed cable-strut structure of this embodiment adopts the classic four-rod twelve-cable prism tension integral basic unit configuration, and forms a double-layer cylindrical tension integral structure through the combination of basic unit nodes and node connections , set short columns 3 at each node of the upper chord cylinder of the cylindrical tensegri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com