H-shaped steel concrete structure

A technology of concrete structure and H-beam, which is applied in building structure, construction, etc., can solve the problems of long manufacturing cycle, high transportation cost, large component volume and own weight, etc., to reduce production cost, facilitate installation, and improve production efficiency. The effect of improving the utilization rate of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

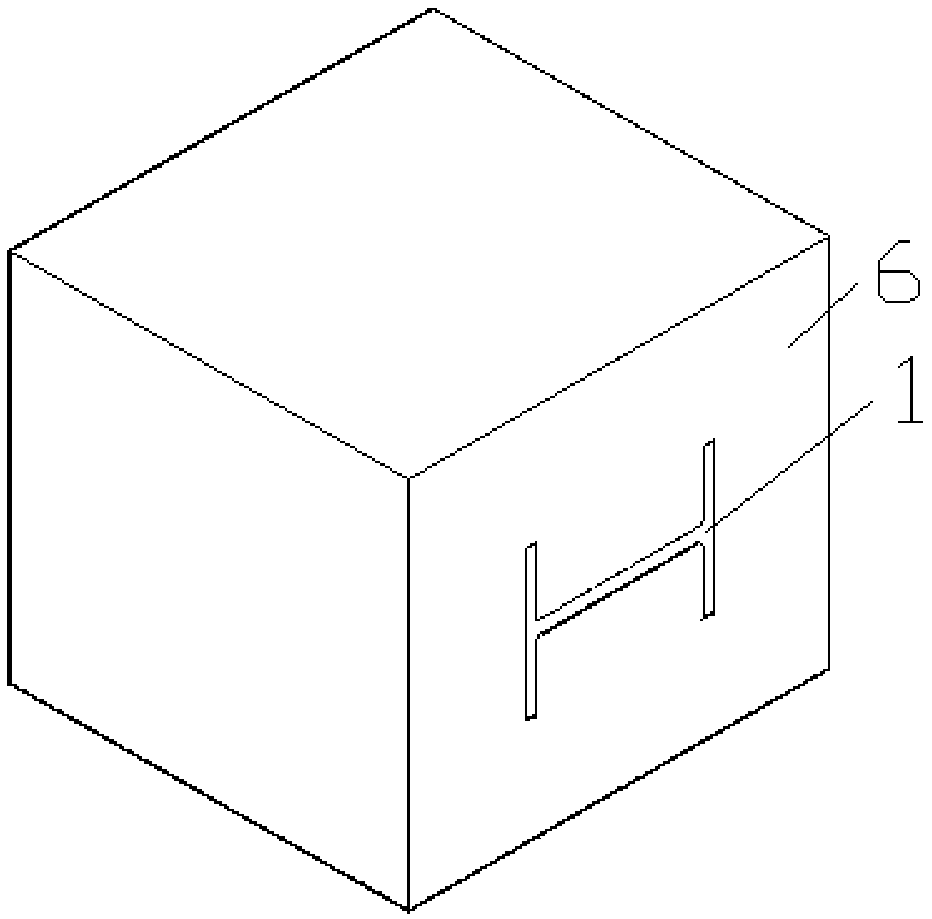

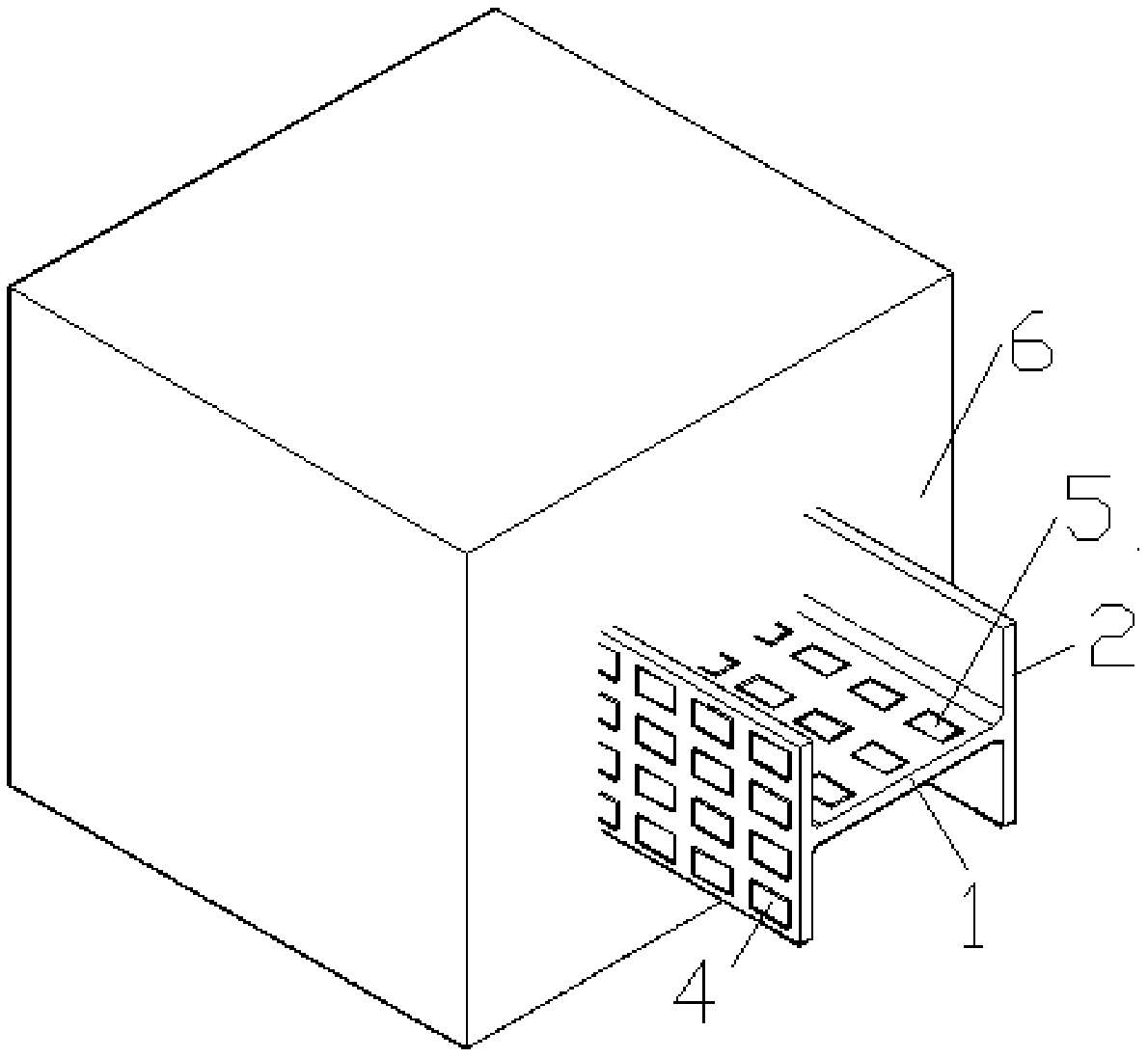

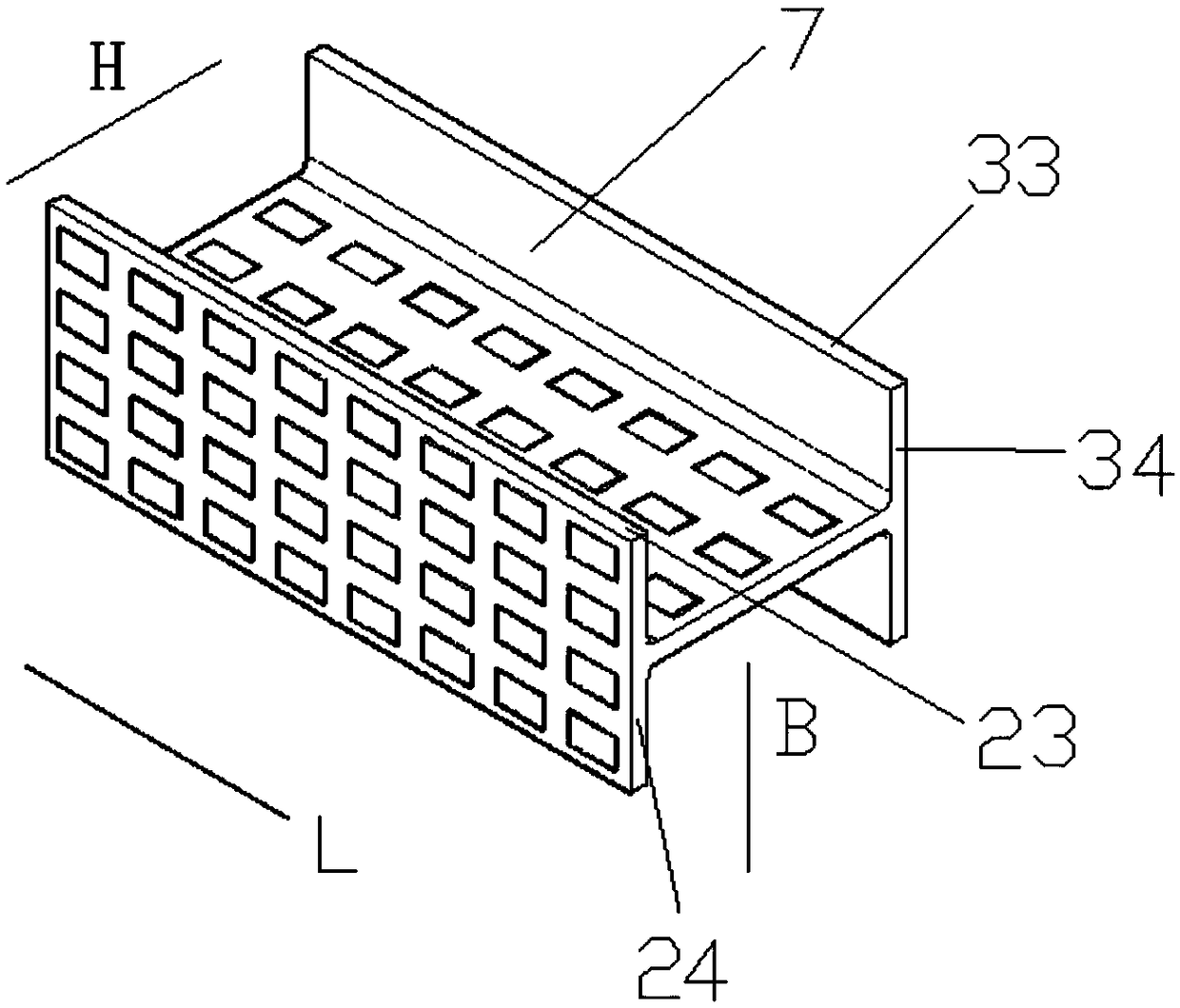

[0035] See Figure 1-6 The embodiment of the present invention provides an H-shaped steel concrete structure, which includes: H-shaped steel 7 and H-shaped steel outer covering concrete 6. The H-shaped steel concrete structure is mainly used to manufacture load-bearing beams and columns. The structure after the above two is mixed can also be called a steel-concrete structure. In order to improve the bearing capacity of the H-shaped steel concrete structure, the number of H-shaped steel placed in the concrete is multiple groups.

[0036] Specifically, the H-shaped steel includes: a web 1, an upper flange 2 (or a first wing) and a lower flange 3 (or a second wing). The two ends of the web 1 are connected to the upper flange 2 and the lower flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com