A prefabricated cold-formed special-shaped steel pipe column-box beam frame joint

A special-shaped steel pipe and box-beam technology, which is applied in construction, building construction, etc., can solve the problems of unfavorable welding construction, difficult handling of cold-formed special-shaped steel pipe column-box-beam frame joints, and difficult control of construction quality. Convenient, conducive to regularization and utilization, and the effect of large width-thickness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the embodiment of the L-shaped column frame node, and the present invention can be implemented in many different ways defined and covered by the claims.

[0036] The invention is an assembled cold-formed special-shaped steel pipe column-box beam frame node, which includes a special-shaped column 1, a box beam 2, a lower U-shaped connector 3, an upper U-shaped connector 4, self-tapping screws 5, and bolts 6. Unilateral bolt 7.

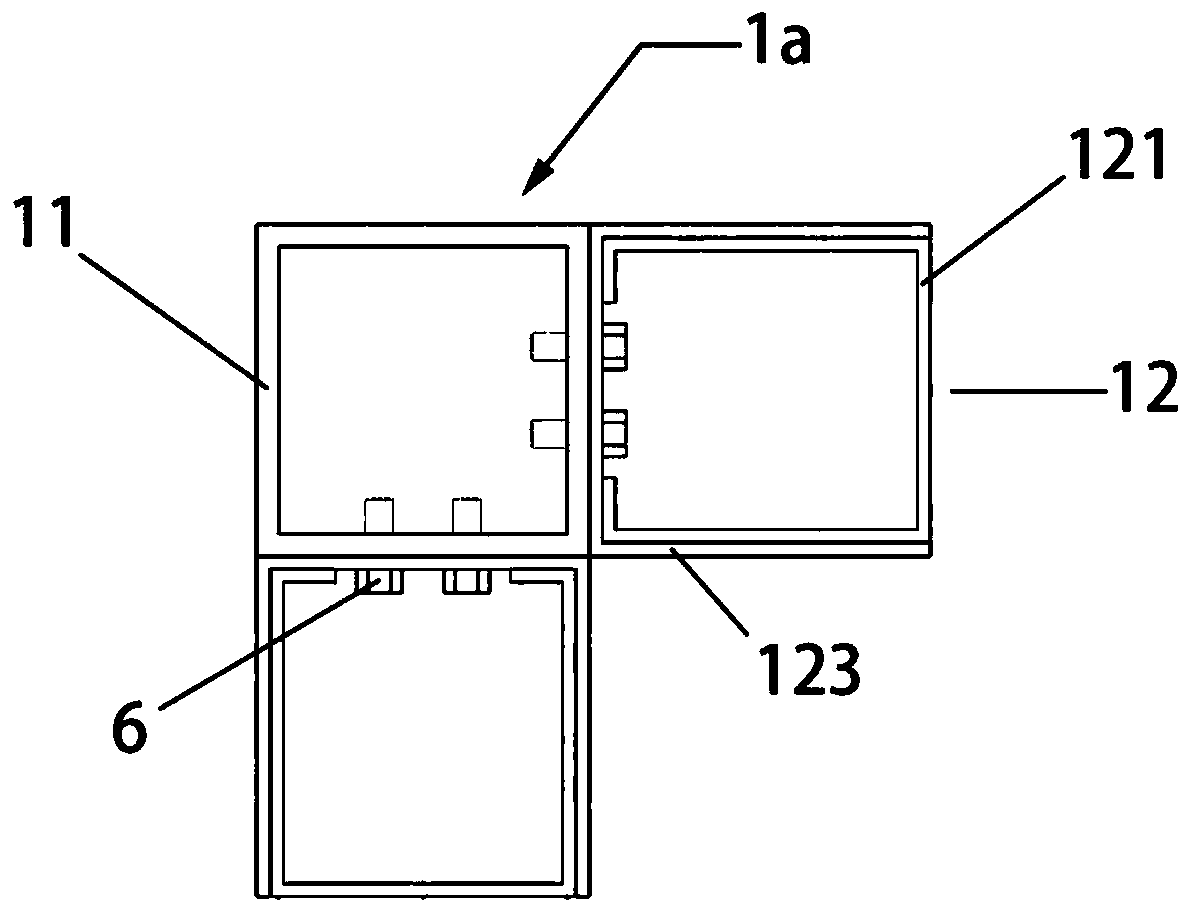

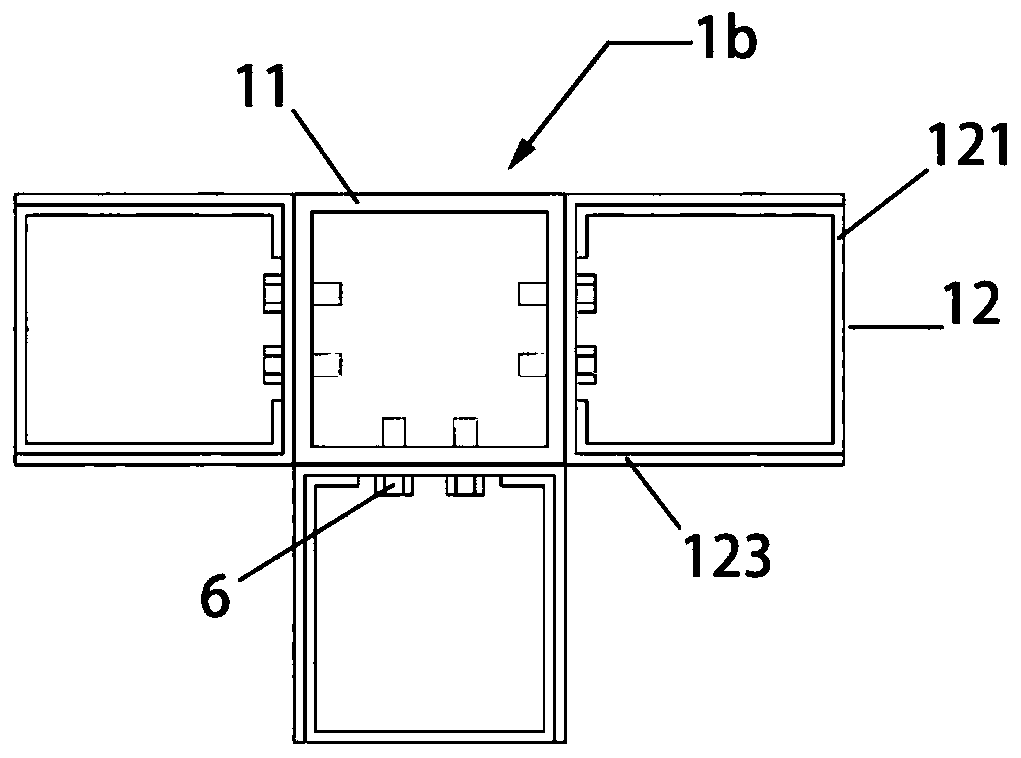

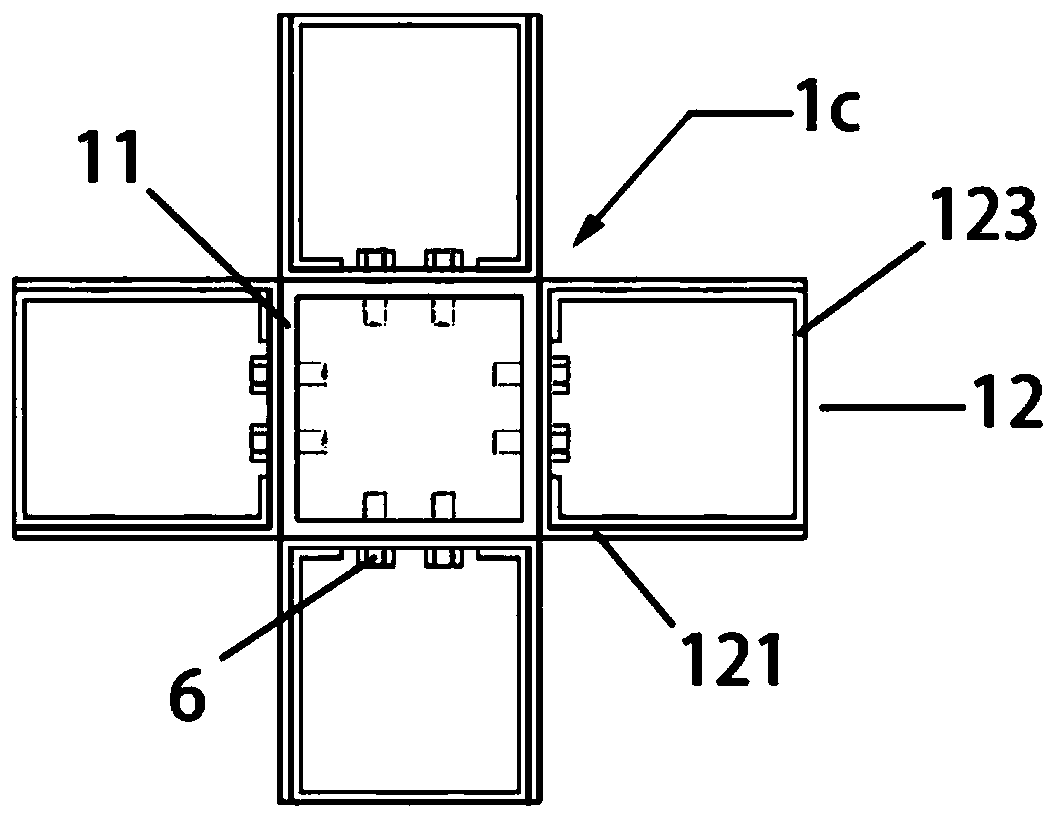

[0037] see Figure 1a-1c In this embodiment, the special-shaped column 1 is a cold-formed steel special-shaped column assembled from a square steel pipe 11 and two box-shaped columns 12 composed of a U-shaped outer column 121, a lower C-shaped inner column 122, and an upper C-shaped inner column 123. steel column.

[0038] see figure 2 In this embodiment, the box girder 2 is a cold-formed thin-walled steel box girder assembled by combining two C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com