Temperature control method for concrete high arch dam in severe cold area

A high arch dam and concrete technology, applied in construction, infrastructure engineering and other directions, can solve the problems of difficult to ensure the safety of the dam body, the influence of the integrity of the dam body, and the difficulty of quality assurance, so as to simplify the temperature control measures and solve the problem of temperature control. Problems, simple and fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

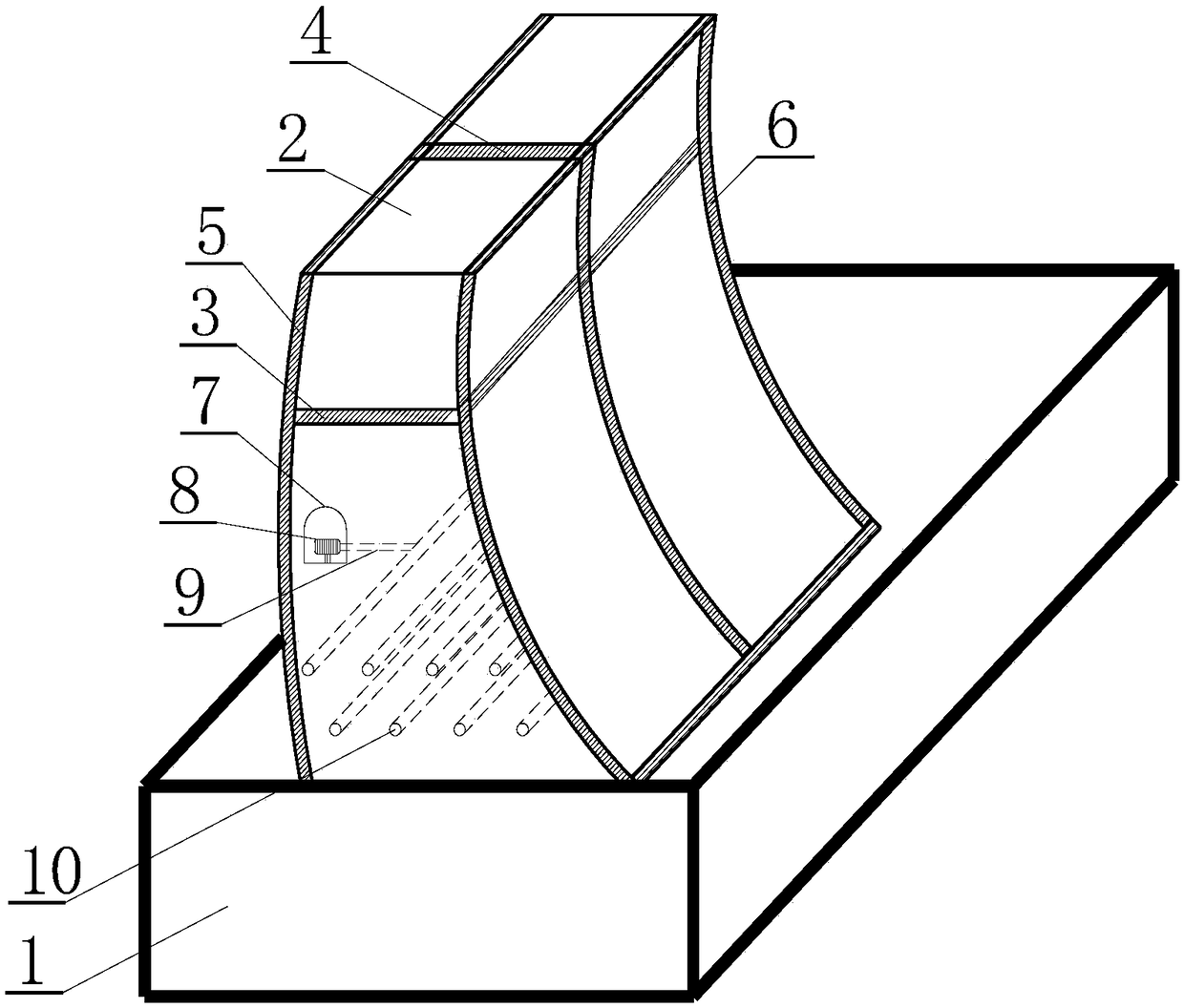

[0012] Such as figure 1 As shown, the temperature control method of the concrete high arch dam in the severe cold area of the present invention, the high arch dam body 2 poured on the bedrock 1 is provided with horizontal joints 3 and vertical joints 4, and the construction period is followed by the construction of the high arch dam body 2 The upstream thermal insulation layer 5 is arranged on the upstream side of the dam body, and the downstream thermal insulation layer 6 is arranged on the downstream side. A corridor 7 is arranged in the dam body 2 of the high arch dam, and a water supply pump 8 is arranged in the corridor 7. The thermal insulation water pipes 10 buried in the serpentine arrangement at the contact position between the dam body 2 and the bedrock 1 of the high arch dam pass water to raise the temperature, so as to maintain a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com