Sidewall structure of roasting furnace

A technology of side wall structure and roasting furnace, which is applied in the direction of integral lining, etc., can solve the problems of increasing fuel consumption, difficulty in temperature regulation, and increasing fuel input in the side fire channel, and achieves simplified temperature regulation measures, guaranteed strength, and simple construction technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

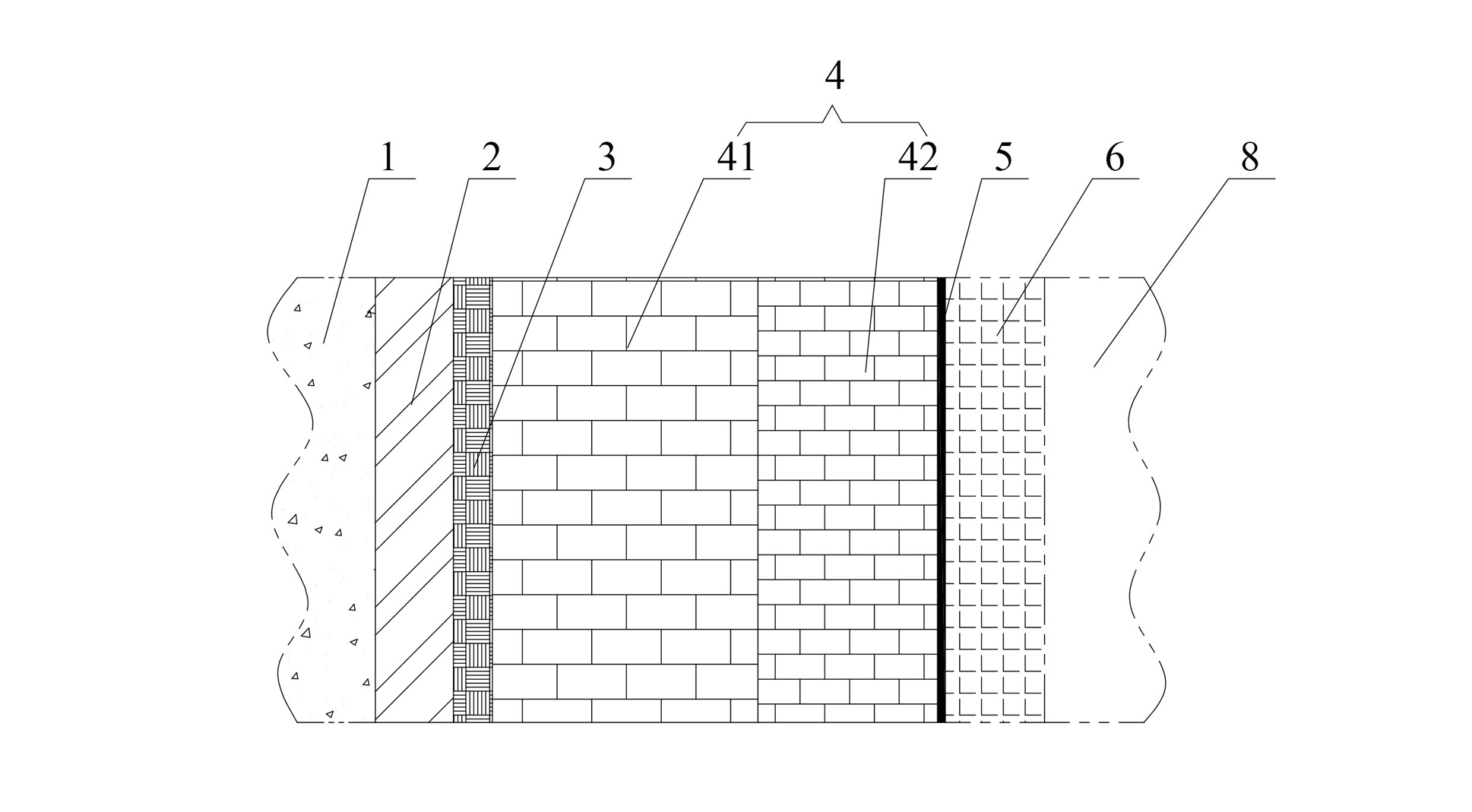

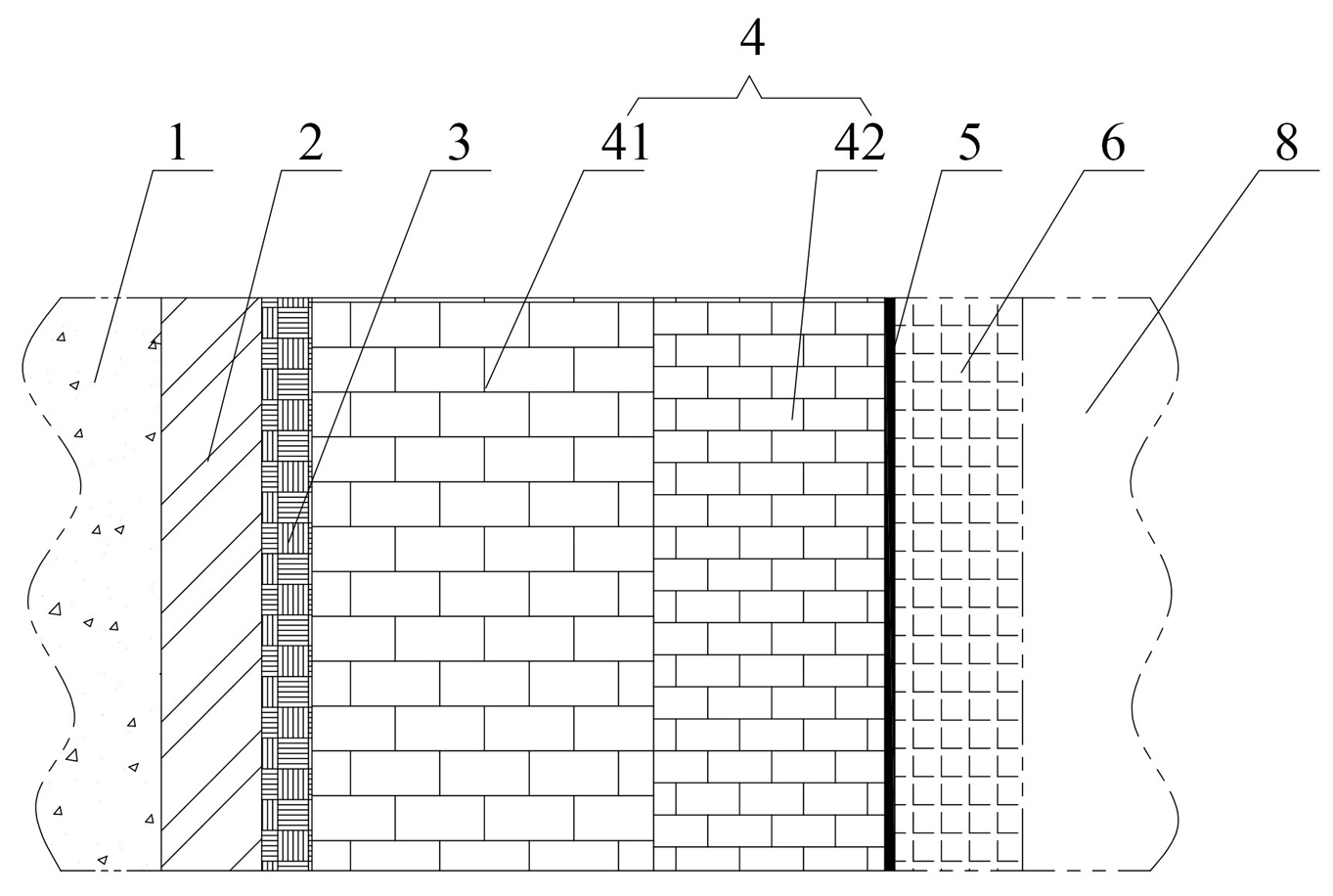

[0020] a kind of like figure 1 The side wall structure of the shown roasting furnace of the present invention, the side wall structure comprises the silicate plate layer 2 close to the inner side of the roasting furnace shell 1 and the refractory mud filler layer close to the outer side of the burning furnace side fire channel 6 5. The inner side of the side fire channel 6 is a material box 8 for placing roasted materials; the middle part from the inner side of the silicate plate layer 2 to the outer side of the refractory mud filler layer 5 is also provided with a silicate fiber layer 3 and a thermal insulation brick layer in turn. 4. The insulating brick layer 4 is composed of a diatomite insulating brick layer 41 close to the inner side of the silicate fiber layer 3 and a high alumina insulating brick layer 42 close to the outer side of the refractory mud filler layer 5 . The silicate plate layer 2 in this embodiment is filled with aluminum silicate plate, and the silicate...

Embodiment 2

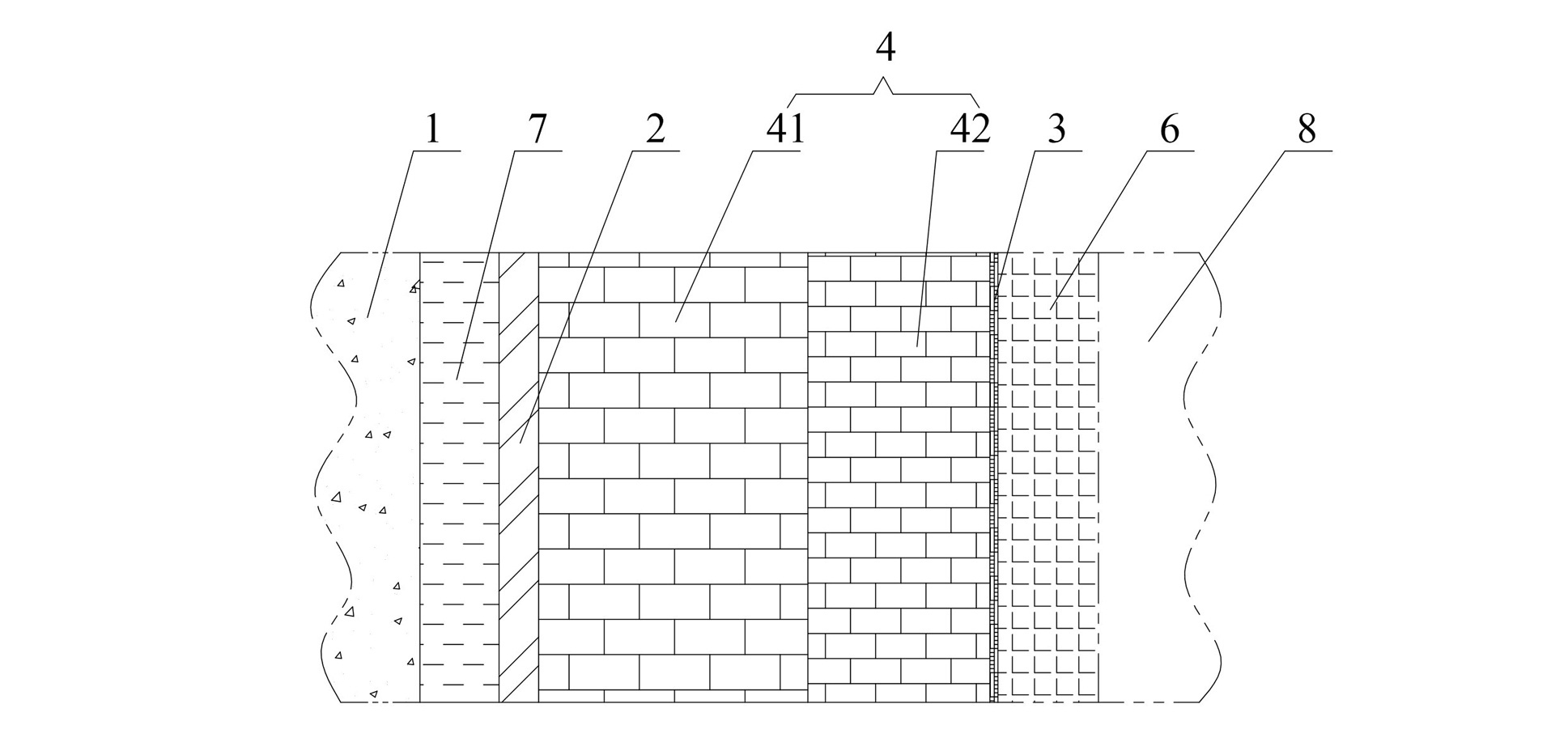

[0024] a kind of like figure 2 The side wall structure of the roasting furnace shown in the present invention, the side wall structure includes the insulation castable layer 7 close to the inner side of the roasting furnace shell 1 and the silicate fiber layer close to the outer side of the roasting furnace side fire channel 6 3. The inner side of the side fire channel 6 is the material box 8 for placing the roasted materials; the middle part from the inner side of the thermal insulation castable layer 7 to the outer side of the silicate fiber layer 3 is also provided with a silicate plate layer 2 and a thermal insulation brick layer in sequence. 4. The insulating brick layer 4 is composed of a diatomite insulating brick layer 41 close to the inner side of the silicate plate layer 2 and a high alumina insulating brick layer 42 close to the outer side of the silicate fiber layer 3 . The silicate plate layer 2 in this embodiment is filled with calcium silicate boards, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com