Production technology of photochromic umbrella fabric

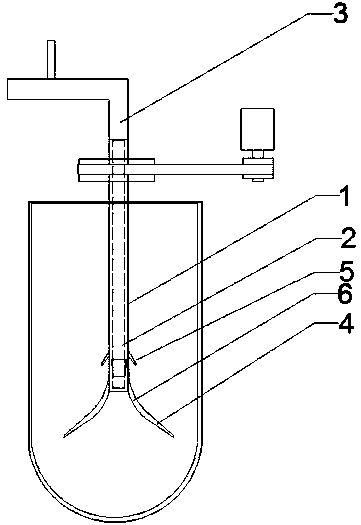

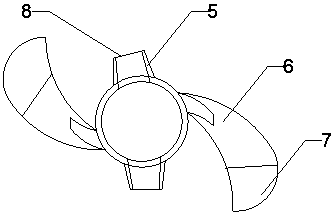

A technology of photochromism and production technology, which is applied in the direction of dyeing method, mixer with rotating stirring device, mixing machine, etc., can solve the problems of insufficient rich color of fabric discoloration, small layers, short service life of fabric discoloration effect, etc., to achieve The effect of enriching the color change, increasing the service life and improving the mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of production technology of photochromic umbrella cloth provided by the invention comprises the following steps:

[0037] 1) Configure pigment printing paste: the formula of the pigment printing paste in weight percent is: 4 parts of photochromic agent, 60 parts of synthetic thickener, 1 part of UV absorber, water-based resin with a solid content of 50%, The rest is water; when preparing pigment printing paste, soak the photosensitive material in water for more than 2 hours first, and pre-disperse it into a paste with a mixer, then add water-based glue and stir evenly, and then combine it with the photochromic agent of the pigment printing paste, and synthesize Thickener and binder are evenly mixed, adding glacial acetic acid at a concentration of 0.3g / L, adjusting the pH value of the pigment printing paste to 7.5, and set aside;

[0038] 2) Printing: use 80-mesh rotary screen printing equipment to perform photochromic printing on the coated fabric;

[0039] 3) ...

Embodiment 2

[0047] Embodiment 2: the production technology of a kind of photochromic umbrella cloth provided by the invention comprises the following steps:

[0048] 1) Configure pigment printing paste: the formula of the pigment printing paste in weight percent is: 6 parts of photochromic agent, 90 parts of synthetic thickener, 2 parts of UV absorber, water-based resin with a solid content of 55%, The rest is water; when preparing pigment printing paste, soak the photosensitive material in water for more than 2 hours first, and pre-disperse it into a paste with a mixer, then add water-based glue and stir evenly, and then combine it with the photochromic agent of the pigment printing paste, and synthesize Thickener and binder are evenly mixed, adding glacial acetic acid at a concentration of 0.3g / L, adjusting the pH value of the pigment printing paste to 8.5, and set aside;

[0049] 2) Printing: use 80-mesh rotary screen printing equipment to perform photochromic printing on the coated fa...

Embodiment 3

[0057] Embodiment 3: the production technology of a kind of photochromic umbrella cloth provided by the invention, comprises the following steps:

[0058] 1) Configure pigment printing paste: the formula of the pigment printing paste in weight percentage is: 5 parts of photochromic agent, 75 parts of synthetic thickener, 1.5 parts of UV absorber, water-based resin with a solid content of 52.55%, The rest is water; when preparing pigment printing paste, soak the photosensitive material in water for more than 2 hours first, and pre-disperse it into a paste with a mixer, then add water-based glue and stir evenly, and then combine it with the photochromic agent of the pigment printing paste, and synthesize The thickener and the adhesive are evenly mixed, and the concentration of 0.3g / L glacial acetic acid is added, and the pH value of the pigment printing paste is adjusted to 8.0, and it is set aside;

[0059] 2) Printing: use 80-mesh rotary screen printing equipment to perform ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com