Preparation method of flexible sulfur/polyacrylonitrile/carbon nano-tube composite fibrous membrane and application

A technology of carbon nanotube composite and polyacrylonitrile, which is applied in the direction of active material electrodes, positive electrodes, electrical components, etc., can solve the problems of battery energy density reduction, unsuitability for industrial production, and cumbersome preparation process, etc., to improve energy density, Good application prospects and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

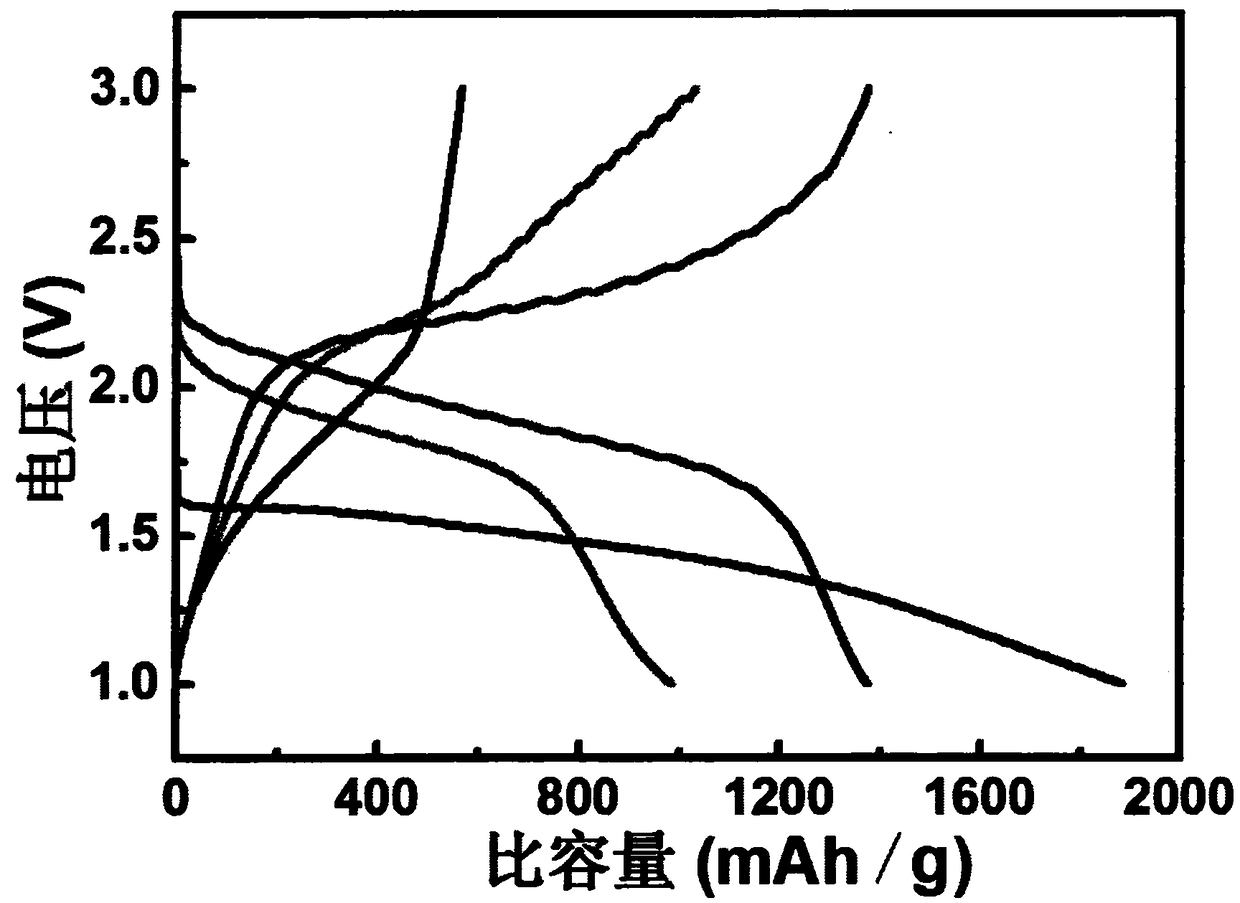

Embodiment 1

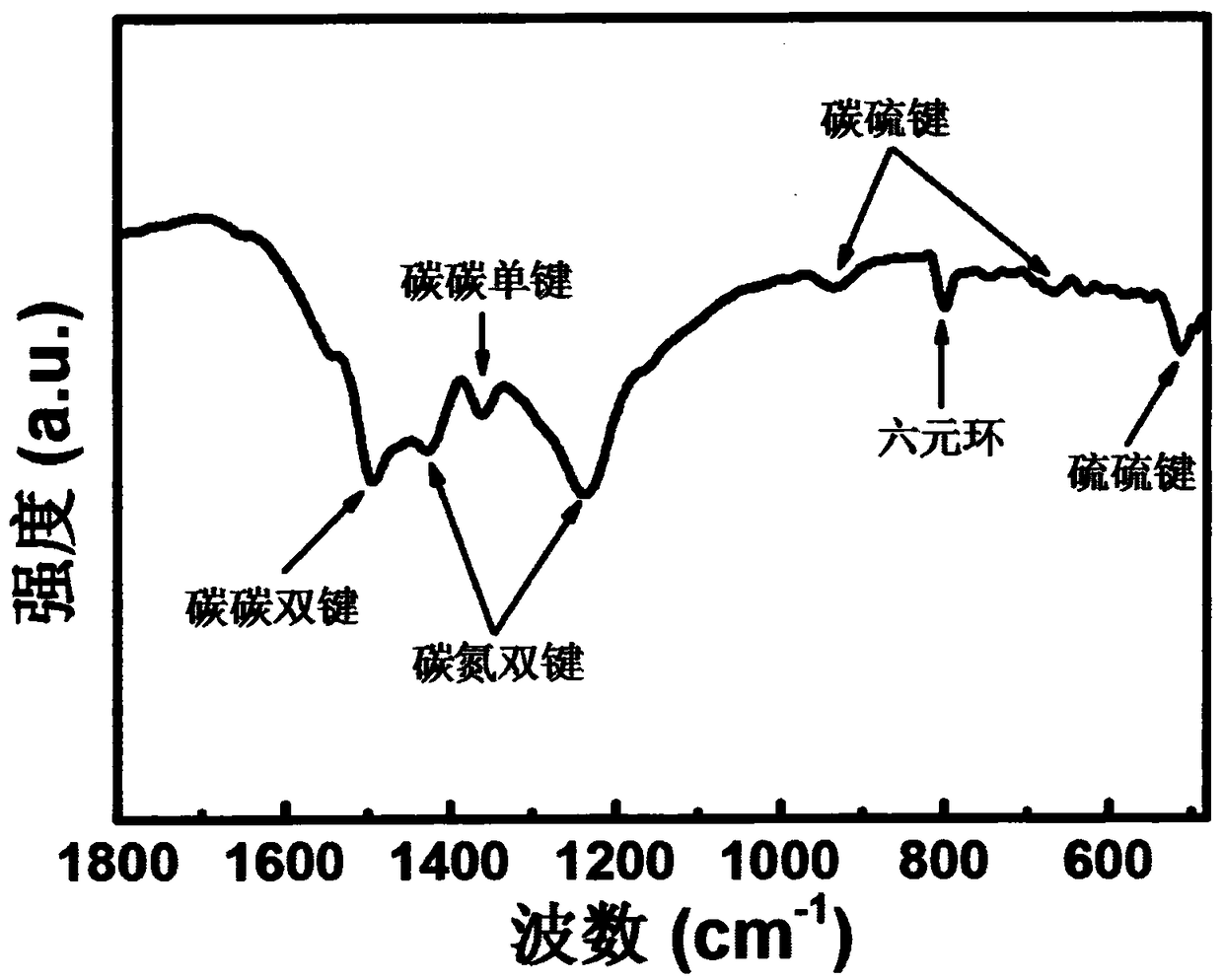

[0033] A preparation method of flexible sulfur / polyacrylonitrile / carbon nanotube composite fiber membrane:

[0034] (1) Add carbon nanotubes into a mixed solution of concentrated sulfuric acid and concentrated nitric acid, heat at a constant temperature at 70° C. and continue magnetic stirring for 1 hour to obtain a black suspension.

[0035] (2) Dilute the suspension obtained above with deionized water, then vacuum filter and wash with deionized water, and finally dry in a vacuum oven at 80° C. for 12 hours to obtain acidified carbon nanotubes.

[0036] (3) 120 mg of acidified carbon nanotubes were weighed and placed in 9 g of N,N-dimethylformamide solvent, ultrasonically dispersed for 45 min, then 1 g of polyacrylonitrile was added and magnetically stirred for 12 h to obtain a uniform and viscous dispersion.

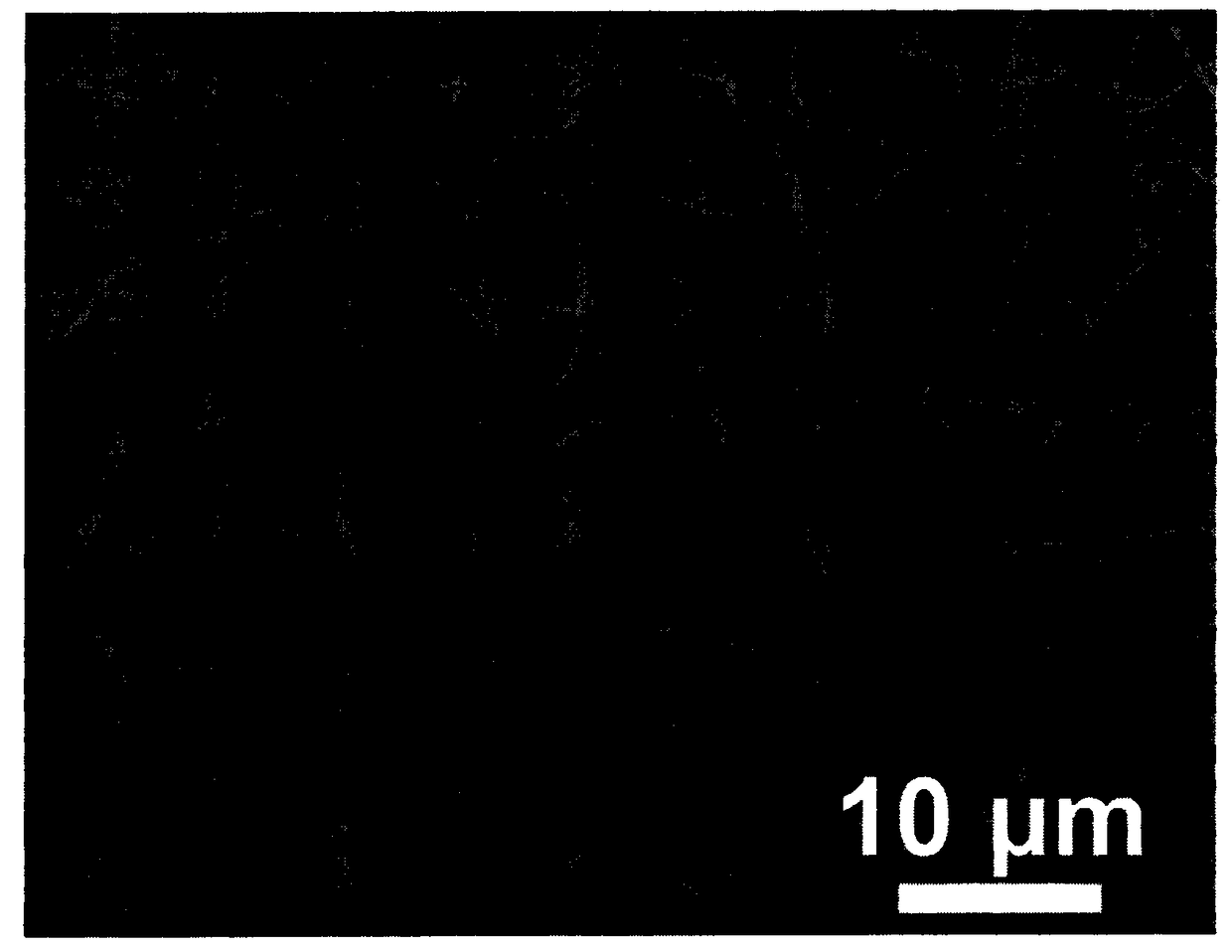

[0037] (4) The obtained dispersion liquid was subjected to electrospinning, and the adjustment process parameters were: electrostatic field voltage 16kV, spinning spee...

Embodiment 2

[0044] A preparation method of flexible sulfur / polyacrylonitrile / carbon nanotube composite fiber membrane:

[0045] (1) Add carbon nanotubes into a mixed solution of concentrated sulfuric acid and concentrated nitric acid, heat at a constant temperature at 70° C. and continue magnetic stirring for 1 hour to obtain a black suspension.

[0046] (2) Dilute the suspension obtained above with deionized water, then vacuum filter and wash with deionized water, and finally dry in a vacuum oven at 80° C. for 12 hours to obtain acidified carbon nanotubes.

[0047] (3) Weigh 80 mg of acidified carbon nanotubes and place them in 9 g of N,N-dimethylformamide solvent, ultrasonically disperse for 45 min, then add 1 g of polyacrylonitrile and continue magnetic stirring for 12 h to obtain a uniform and viscous dispersion.

[0048] (4) The obtained dispersion liquid was subjected to electrospinning, and the adjustment process parameters were: electrostatic field voltage 16kV, spinning speed 0.1...

Embodiment 3

[0051] A preparation method of flexible sulfur / polyacrylonitrile / carbon nanotube composite fiber membrane:

[0052] (1) Add carbon nanotubes into a mixed solution of concentrated sulfuric acid and concentrated nitric acid, heat at a constant temperature at 70° C. and continue magnetic stirring for 1 hour to obtain a black suspension.

[0053] (2) Dilute the suspension obtained above with deionized water, then vacuum filter and wash with deionized water, and finally dry in a vacuum oven at 80° C. for 12 hours to obtain acidified carbon nanotubes.

[0054] (3) Weigh 40 mg of acidified carbon nanotubes and place them in 9 g of N,N-dimethylformamide solvent, ultrasonically disperse for 45 min, then add 1 g of polyacrylonitrile and continue magnetic stirring for 12 h to obtain a uniform and viscous dispersion.

[0055] (4) The obtained dispersion liquid was subjected to electrospinning, and the adjustment process parameters were: electrostatic field voltage 16kV, spinning speed 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com