A kind of magnesium-based metal material conversion film and preparation method thereof

A magnesium-based metal, conversion coating technology, applied in the field of medical materials, can solve the problems of low structural stability, poor long-term corrosion resistance, etc., and achieves easy control of raw material dosage, good long-term corrosion resistance, and universality. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A magnesium-based metal material conversion film, the conversion film includes a Mg-Si alloy substrate and a polyphenol-organic conversion layer attached to the surface of the Mg-Si alloy substrate; the polyphenol-organic conversion layer has 3 layers, and is composed of tanshinone (Tanshinone) and Mg 2+ chelated with each other. The magnesium-based metal material conversion coating is prepared through the following steps:

[0027] (1) Carry out polishing, cleaning and drying treatment to Mg-Si alloy substrate successively, obtain magnesium-based material;

[0028] (2) Soak the magnesium-based material in a NaOH solution with a temperature of 70°C and a concentration of 3M, take it out after reacting for 30 minutes, wash it with absolute ethanol, then dry it with nitrogen, and put it in a vacuum drying box for standby;

[0029] (3) Submerge the magnesium-based material treated in step (2) in a tanshinone solution with a pH of 8.0 and a concentration of 0.01 mM, and th...

Embodiment 2

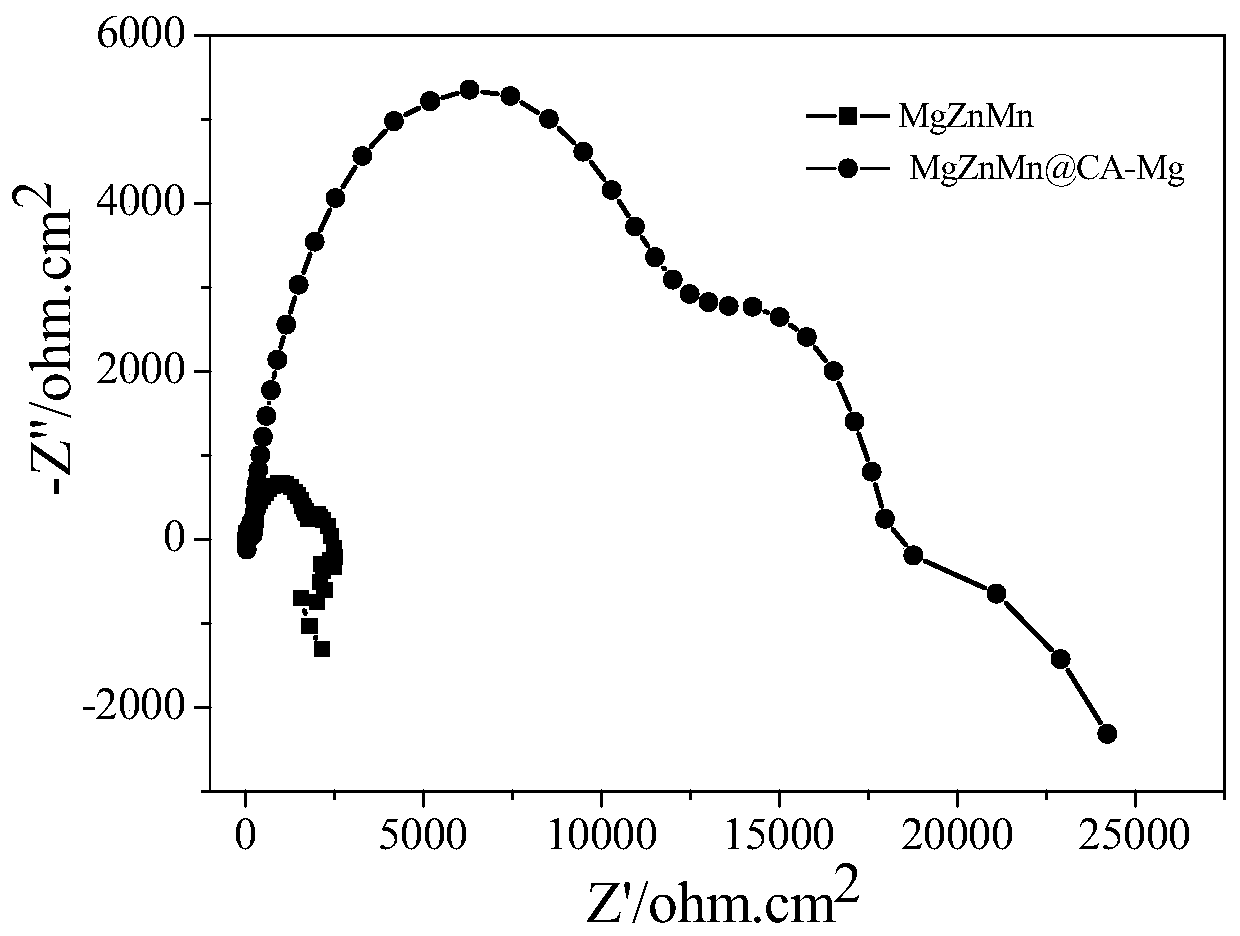

[0032] A magnesium-based metal material conversion coating, the conversion coating comprises a MgZnMg alloy base material and a polyphenol-organic conversion layer attached to the surface of the MgZnMg alloy base material; the polyphenol-organic conversion layer has 3 layers, and consists of catechol ( CA) and Mg 2+ chelated with each other. The magnesium-based metal material conversion coating is prepared through the following steps:

[0033] (1) sequentially polishing, cleaning and drying the MgZnMg alloy substrate to obtain a magnesium-based material;

[0034] (2) Soak the magnesium-based material in a NaOH solution with a temperature of 60°C and a concentration of 3M, take it out after reacting for 35 minutes, wash it with absolute ethanol, then dry it with nitrogen, and put it in a vacuum drying oven for standby;

[0035] (3) Submerge the magnesium-based material treated in step (2) in a CA solution with a pH of 9.0 and a concentration of 1 mM, and then place it in a wa...

Embodiment 3

[0038] A magnesium-based metal material conversion coating, the conversion coating includes an AZ91 magnesium alloy base material and a polyphenol-organic conversion layer attached to the surface of the AZ91 magnesium alloy base material; the polyphenol-organic conversion layer has two layers, and consists of epicatechin Ethyl Gallate (ECG) and Mg 2+ chelated with each other. The magnesium-based metal material conversion coating is prepared through the following steps:

[0039] (1) Carry out polishing, cleaning and drying treatment to AZ91 magnesium alloy substrate successively, obtain magnesium-based material;

[0040] (2) Soak the magnesium-based material in a NaOH solution with a temperature of 65°C and a concentration of 3M, take it out after reacting for 35 minutes, wash it with absolute ethanol, then dry it with nitrogen, and put it in a vacuum drying oven for later use;

[0041](3) Immerse the magnesium-based material treated in step (2) in an ECG solution with a pH o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com