Glass clarifier, boroaluminosilicate glass and preparation method thereof, glass substrate and display

A boroaluminosilicate and glass substrate technology, applied in the field of glass manufacturing, can solve problems such as energy consumption, increase manufacturing cost, environmental pollution, etc., and achieve the effects of improving service life, increasing manufacturing cost, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

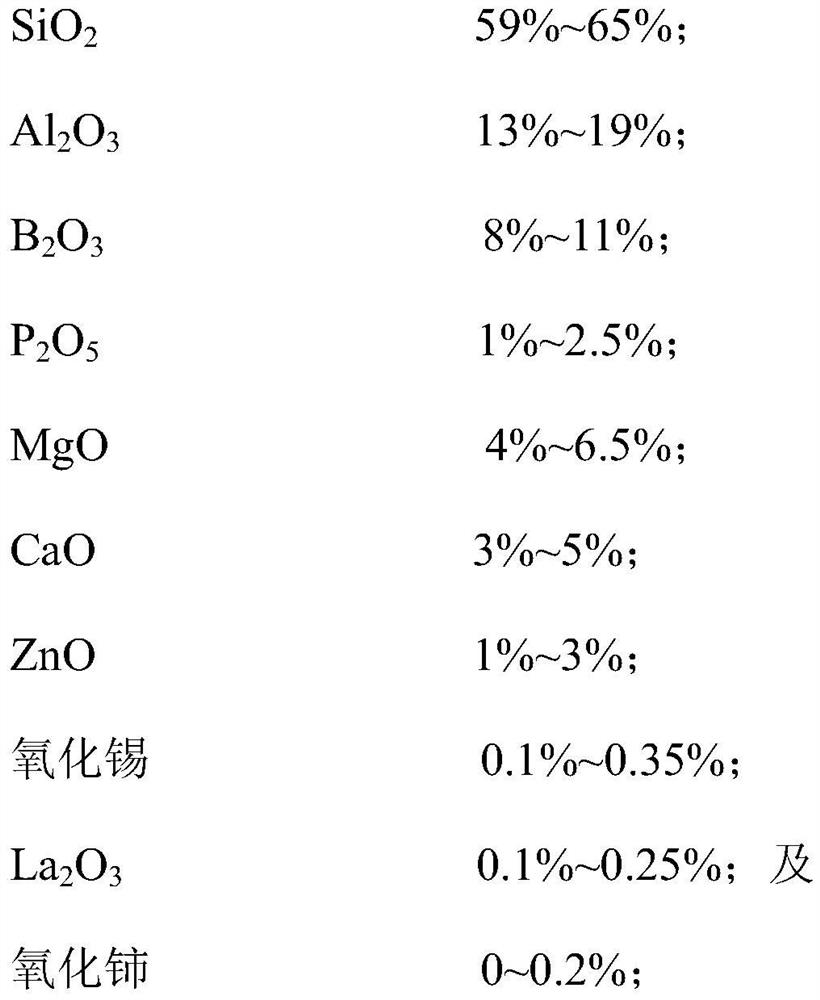

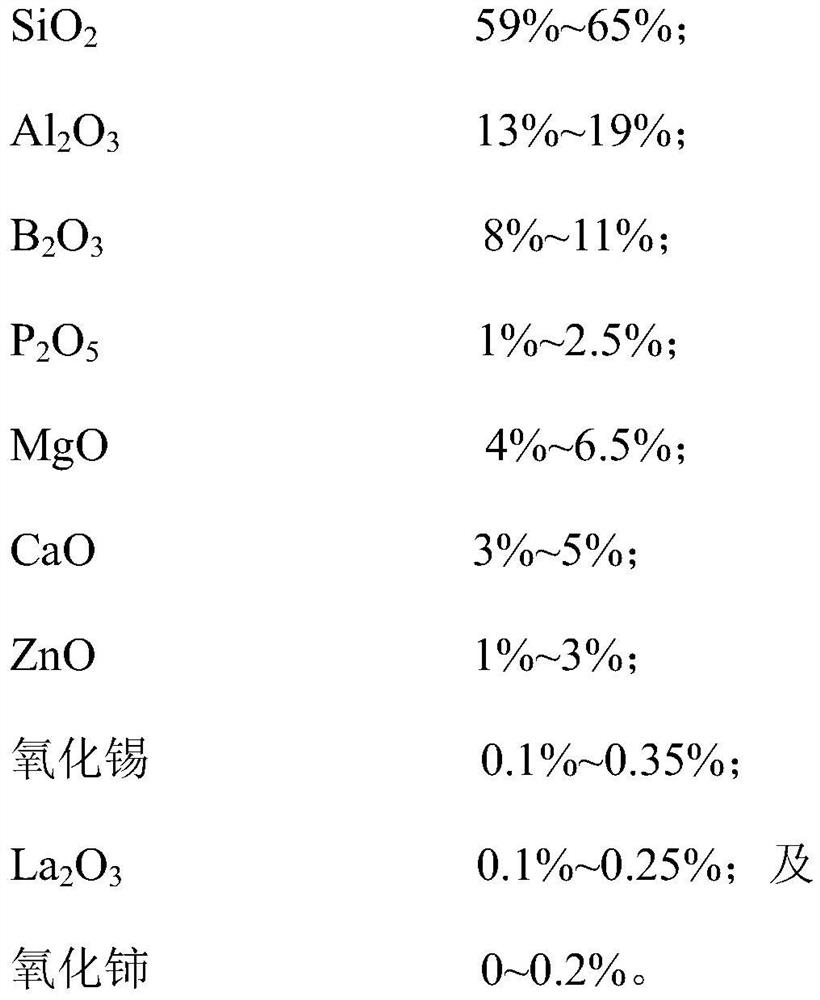

[0046] like figure 1 As shown, the method for preparing boroaluminosilicate glass according to one embodiment is a method for preparing boroaluminosilicate glass mentioned above. The preparation method of the boroaluminosilicate glass comprises the following steps:

[0047] Step S110: Mix raw materials containing silicon, aluminum, boron, phosphorus, magnesium, calcium, and zinc with a glass clarifying agent, and then perform melting treatment at 1590°C to 1640°C to obtain molten glass.

[0048] Among them, the glass clarifier is the above-mentioned glass clarifier.

[0049] Specifically, raw materials containing silicon, aluminum, boron, phosphorus, magnesium, calcium, and zinc include silicon sources, aluminum sources, boron sources, phosphorus sources, magnesium sources, calcium sources, and zinc sources. Among them, the silicon source is quartz sand; the aluminum source is alumina powder; the boron source is boric acid or boric anhydride; the phosphorus source is ammoniu...

Embodiment 1~ Embodiment 6

[0058] The preparation process of boroaluminosilicate glass of embodiment 1~embodiment 6 is as follows:

[0059] (1) Weigh the raw material and the glass clarifier according to the mass percentage of each component of the boroaluminosilicate glass in Table 1, and mechanically mix the raw material and the glass clarifier for 1 hour to obtain the raw material.

[0060](2) Pour the raw materials into a platinum-rhodium crucible, heat and melt at 1590° C. for 8 hours to obtain molten glass.

[0061] (3) The molten glass is poured into a stainless steel mold for molding, and then heat-preserved and annealed at 730°C for 3 hours, and then cooled to room temperature with the furnace to obtain boroaluminosilicate glass.

Embodiment 7~ Embodiment 12

[0063] The preparation process of the boroaluminosilicate glass of Embodiment 7 to Embodiment 12 is as follows:

[0064] (1) Weigh the raw material and the glass clarifier according to the mass percentage of each component of the boroaluminosilicate glass in Table 2, and mechanically mix the raw material and the glass clarifier for 1 hour to obtain the raw material.

[0065] (2) Pour the raw materials into a platinum-rhodium crucible, heat-preserve and melt at 1620° C. for 6 hours to obtain molten glass.

[0066] (3) The molten glass is poured into a stainless steel mold for molding, and then heat-preserved and annealed at 750°C for 2 hours, and then cooled to room temperature with the furnace to obtain boroaluminosilicate glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com