A display control layout adjustment system

A layout adjustment and display device technology, applied in the field of avionics systems, can solve the problems of inability to realize rapid adjustment of display and control layout, long iteration cycle, high iteration cost, etc., and achieve the effect of shortening iteration cycle, reducing iteration cost, and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

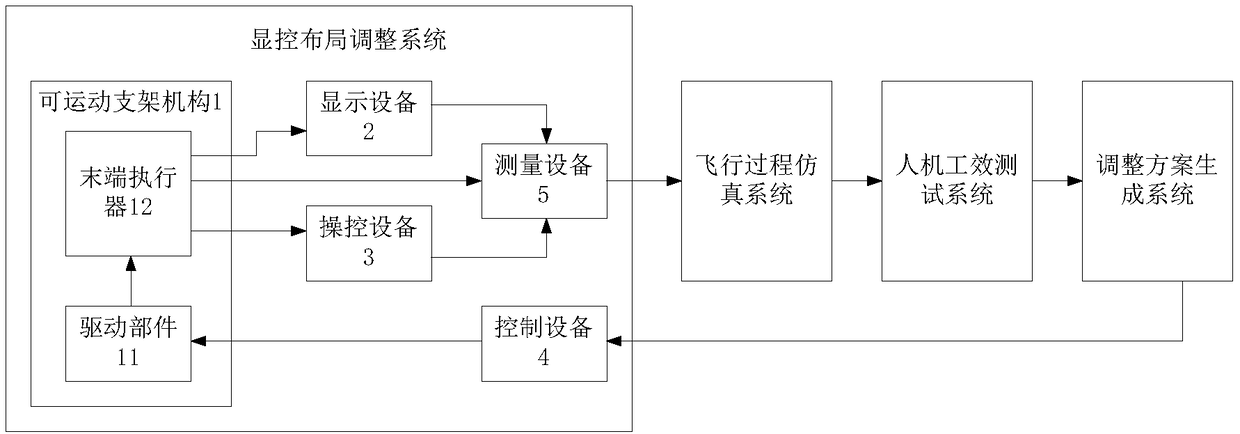

[0049] figure 1 It is a schematic composition diagram of the display and control layout verification and optimization platform provided in Embodiment 1 of the present application.

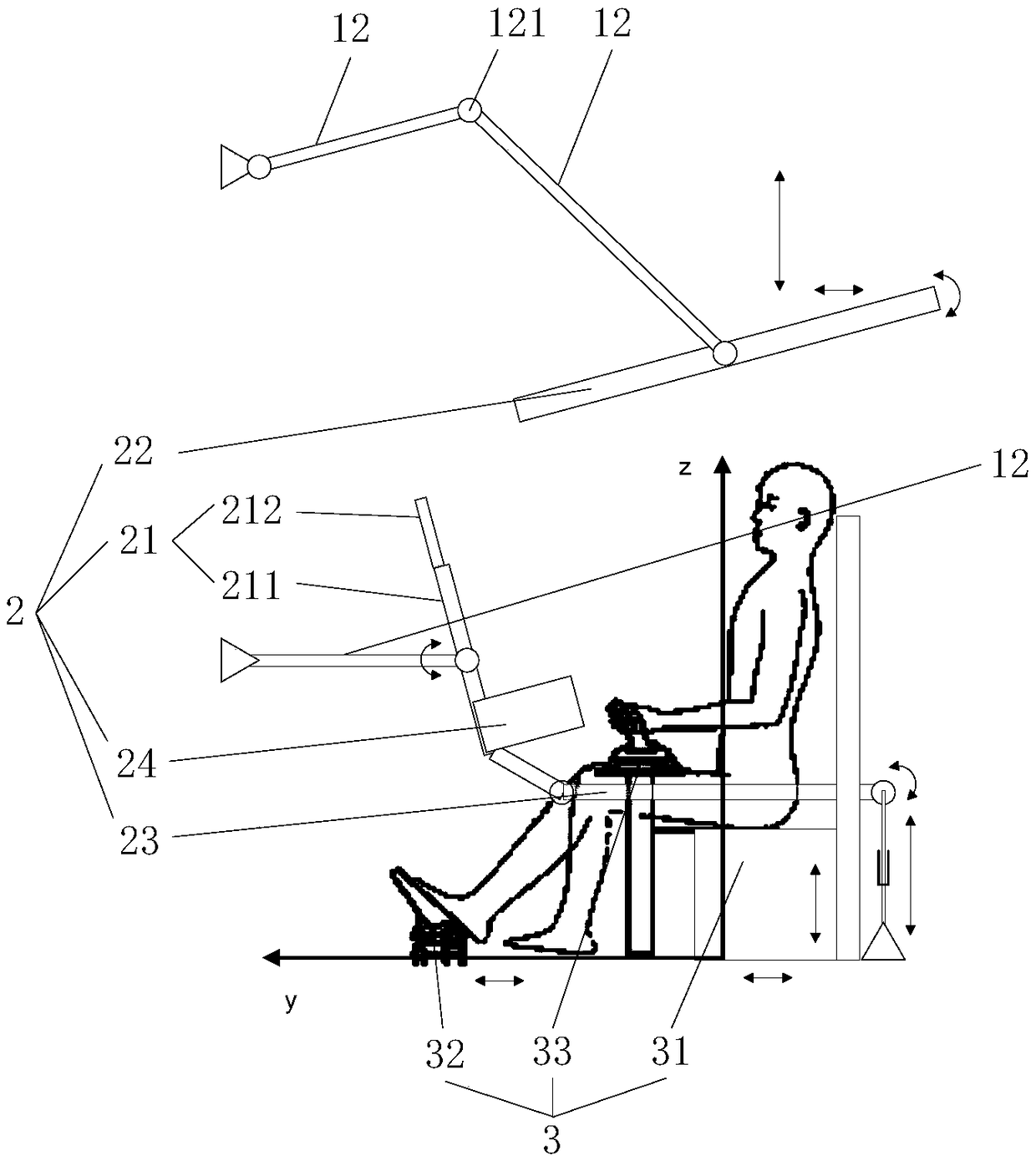

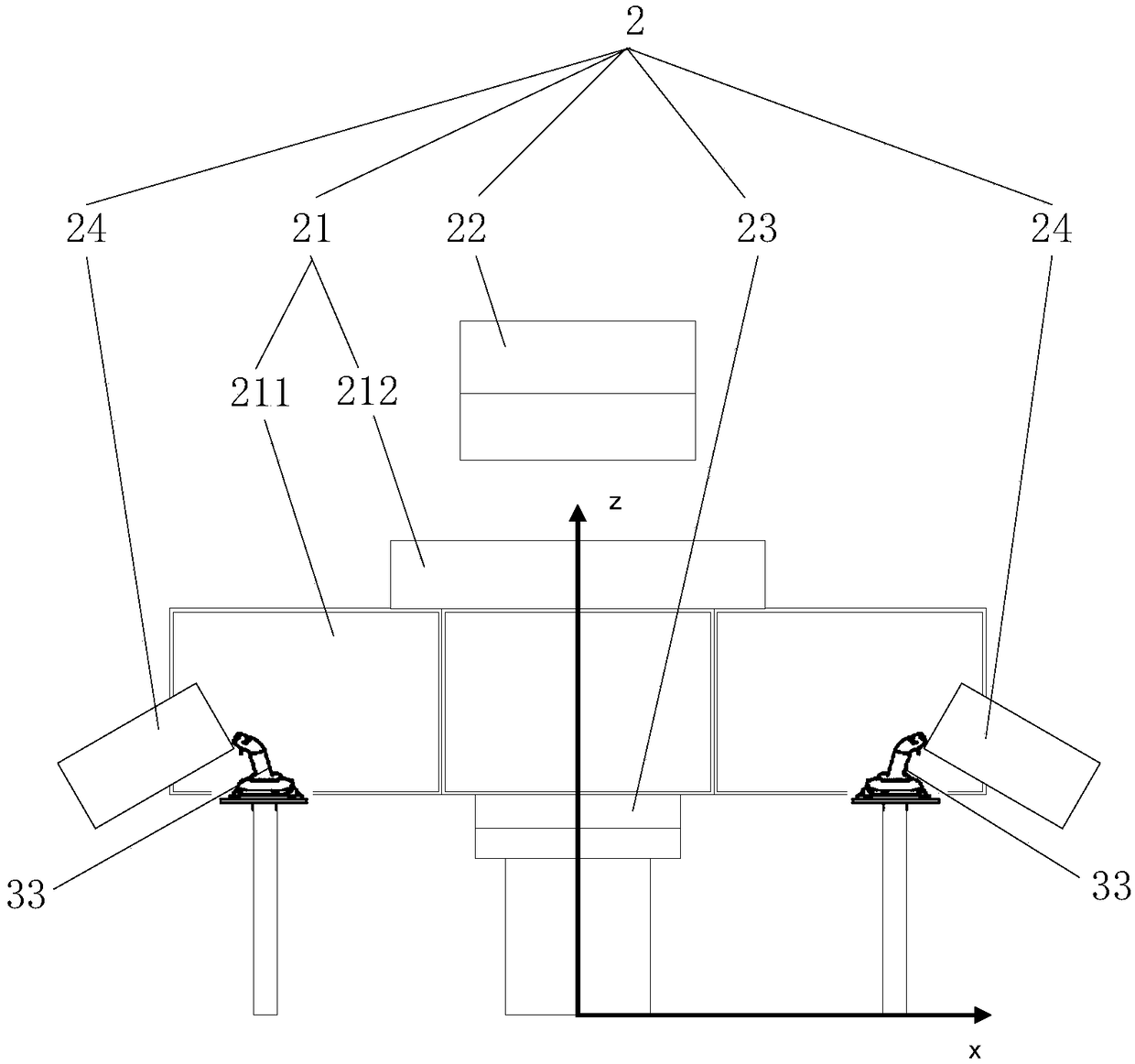

[0050] figure 2 It is a schematic structural diagram of the display and control layout adjustment system provided in Embodiment 1 of the present application.

[0051] Please refer to figure 1 , figure 2 , this embodiment provides a display and control layout adjustment system, including: a movable bracket mechanism 1 , a display device 2 , a manipulation device 3 and a control device 4 .

[0052] The movable support mechanism 1 includes a driving part 11 and a plurality of end effectors 12 connected to the driving part 11 , and each end effector 12 is provided with a movable joint 121 .

[0053] The display device 2 includes multiple panels, and each panel is connected to at least one end effector 12 .

[0054] The control device 3 includes two driver's seats 31 and pedals 32 , and the drive...

Embodiment 2

[0093] The difference between this embodiment and Embodiment 1 is that the movable support mechanism 1 is an active structure, and the power source of the driving part 11 is a steering gear or a motor with signal feedback, and the movable joint 121 is driven and controlled by automatic control. move and hold at the preset position. Specifically, when the movable support mechanism 101 is an active structure, the driving part 11 is driven by a steering gear or a motor with signal feedback, so that all movable joints 121 on the end effector 12 have the ability to actively run and brake.

[0094] The structure, composition and connection relationship of other parts in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0096] The difference between this embodiment and Embodiment 1 is that the movable support mechanism 1 is a passive structure, the power source of the driving part 11 is artificial, and the movable joint 121 is adjusted to a preset position through manual control, and the lock, buckle, The latch or the friction plate is locked to realize the passive operation and braking of the movable joint 121 . Specifically, in this embodiment, all the movable joints 121 on the end effector 12 do not have the ability to actively run and brake, and need to be operated and braked manually by the operator.

[0097] The structure, composition and connection relationship of other parts in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com