Coating material register hot-pressing production device

A technology of coating materials and production equipment, applied in the field of machinery, can solve problems such as difficult to accurately align flowers, scrap, and affect product quality, achieve realistic three-dimensional patterns, ensure the accuracy of pattern alignment, and improve the quality of patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

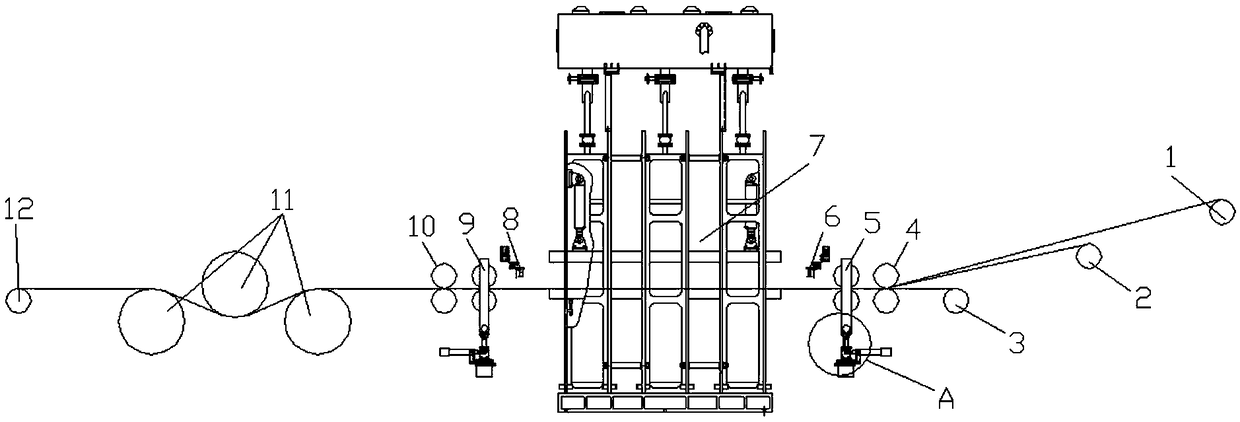

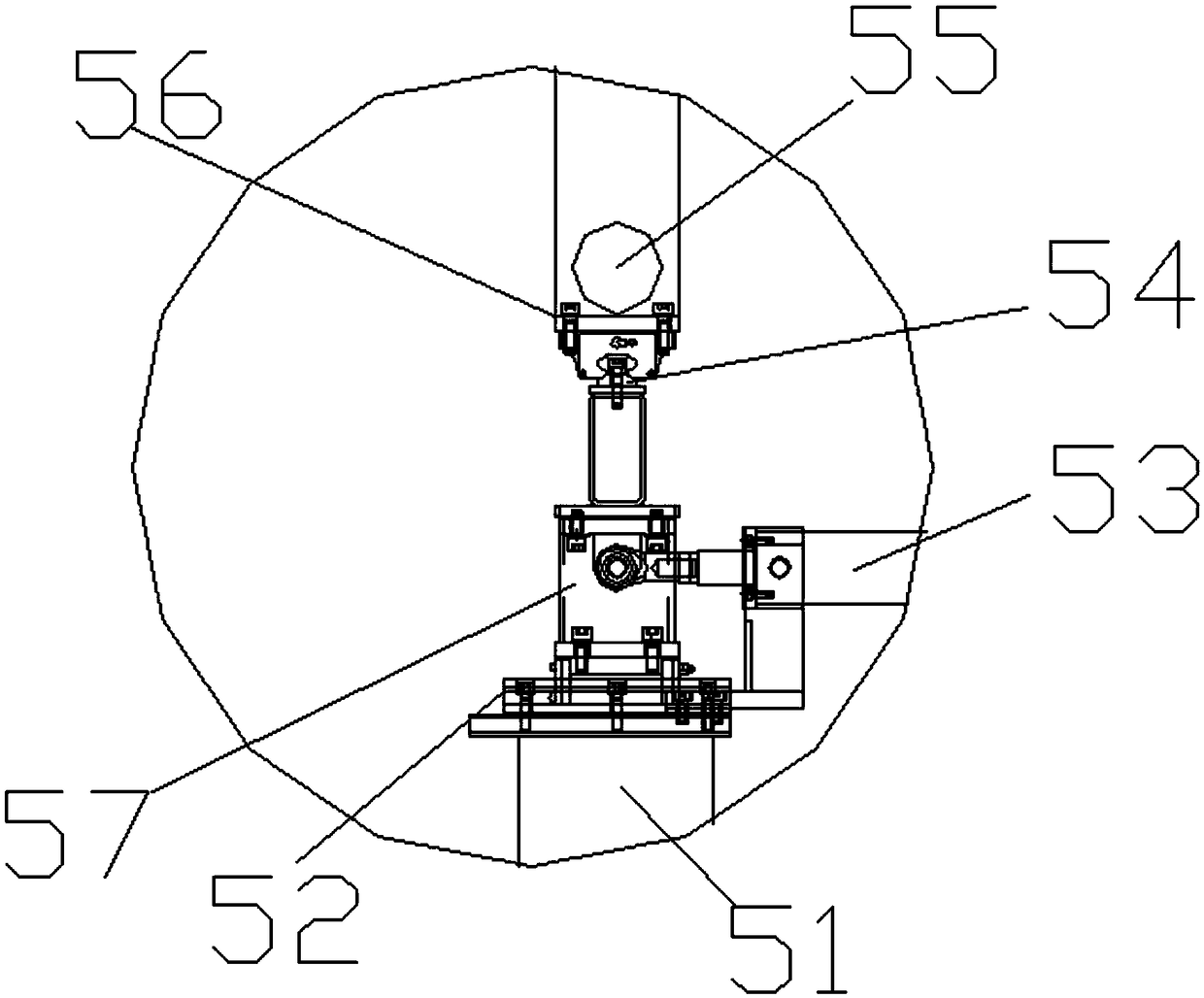

[0019] Combine below Figure 1 ~ Figure 2 And further illustrate the technical solution of the present invention through specific examples.

[0020] A device for hot-pressing production of cladding materials, including: a controller, a winding roller 12, a hot press 7, a first visual inspection device 6, a second visual inspection device 8, a first clamping assembly 5, a second The clamping assembly 9, the first slack assembly 4, the second slack assembly 10, and a plurality of unwinding rollers, the plurality of unwinding rollers, the first slack assembly 4, the first clamping assembly 5, and the first visual inspection device 6 , hot press 7, second visual detection device 8, second clamping assembly 9, second loosening assembly 10 and take-up roller 12 are arranged in assembly line from front to back, and are connected linearly with controller respectively, and described controller It is a PLC controller to realize automatic production.

[0021] The plurality of unwinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com