Mechanical equipment for automatically cutting steel bars

A mechanical equipment, automatic cutting technology, applied in the field of cutting machinery, can solve the problem of unsafe automatic cutting degree of steel cutting equipment, and achieve the effect of high degree of automation and reasonable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

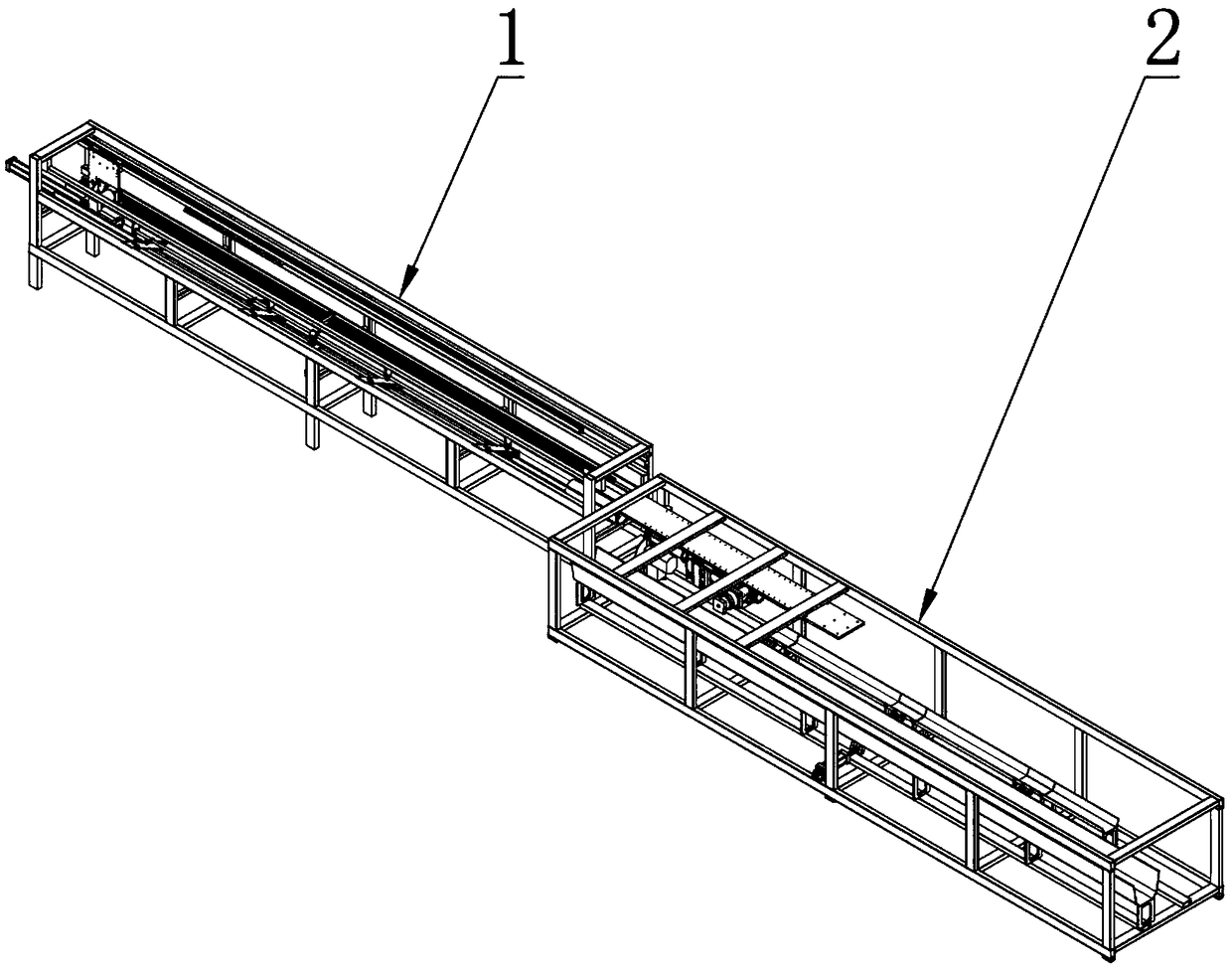

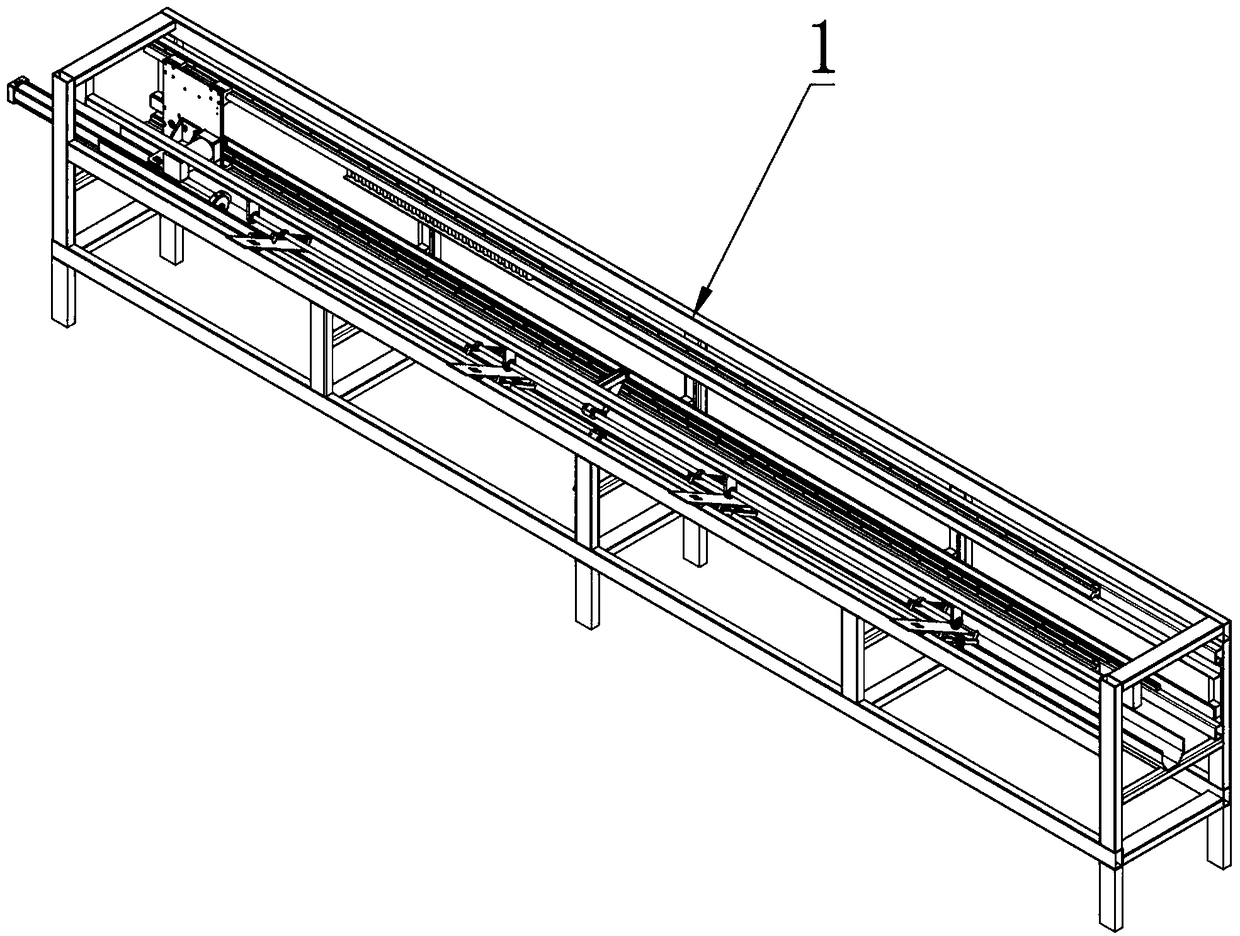

[0052] Such as Figure 1 to Figure 8 As shown, a mechanical device for automatically cutting steel bars according to the present invention includes a feeding device 1, a cutting device 2, a clamp set and an electrical control system connecting various functional devices. The feeding device 1 is used to connect the external steel bar conveyor belt, count and count the steel bars, feed a single steel bar each time, and push it into the cutting device 2 for accurate cutting according to the required length. During the cutting process, the two ends of the steel bar are compressed by the clamp group to avoid the bouncing and shaking of the steel bar. The cutting process of the mechanical equipment provided by the invention does not require manual intervention, is efficient and reliable, and the equipment is more suitable for one-time forming and cutting of long steel bars or steel pipes.

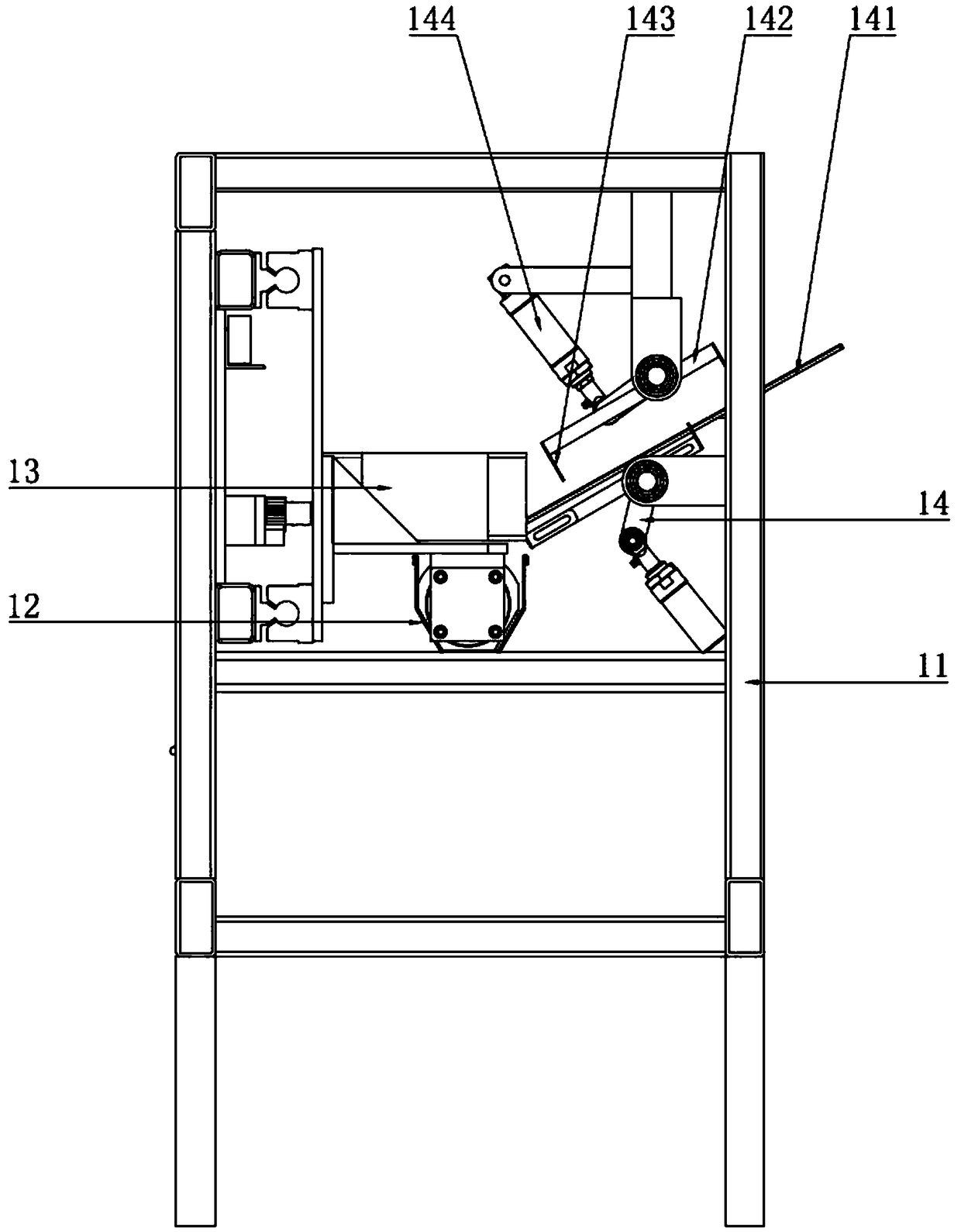

[0053] The feeding device 1 has a body consisting of a feeding frame 11 and a visible protec...

Embodiment 2

[0072] Embodiment 2 is a description of the electrical control system of the mechanical equipment for automatically cutting steel bars in Embodiment 1 above.

[0073] The electrical control system includes a PLC controller, a solenoid valve group of a cylinder, an operation panel and a detection sensor assembly. The PLC controller is respectively connected with the operation panel, the detection sensor assembly, the electromagnetic valve group and the feeding device, the cutting device and the electrical components in the clamp group in Embodiment 1. Realize the complete control loop of this mechanical equipment.

[0074] Specifically, the solenoid valve group is used to connect the pneumatic components in the feeding device, the cutting device and the clamp group with the external air supply source, and the action of each pneumatic component is controlled by PLC. The detection sensor assembly includes a first travel switch group, a second travel switch group, several magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com