Crushing packing device for garden cleaning

A garden and pulverizer technology, which is applied in grain processing, presses, manufacturing tools, etc., can solve the problems of blade damage, inability to handle stones, etc., and achieve the effect of reducing the possibility of damage, reducing the possibility, and speeding up the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

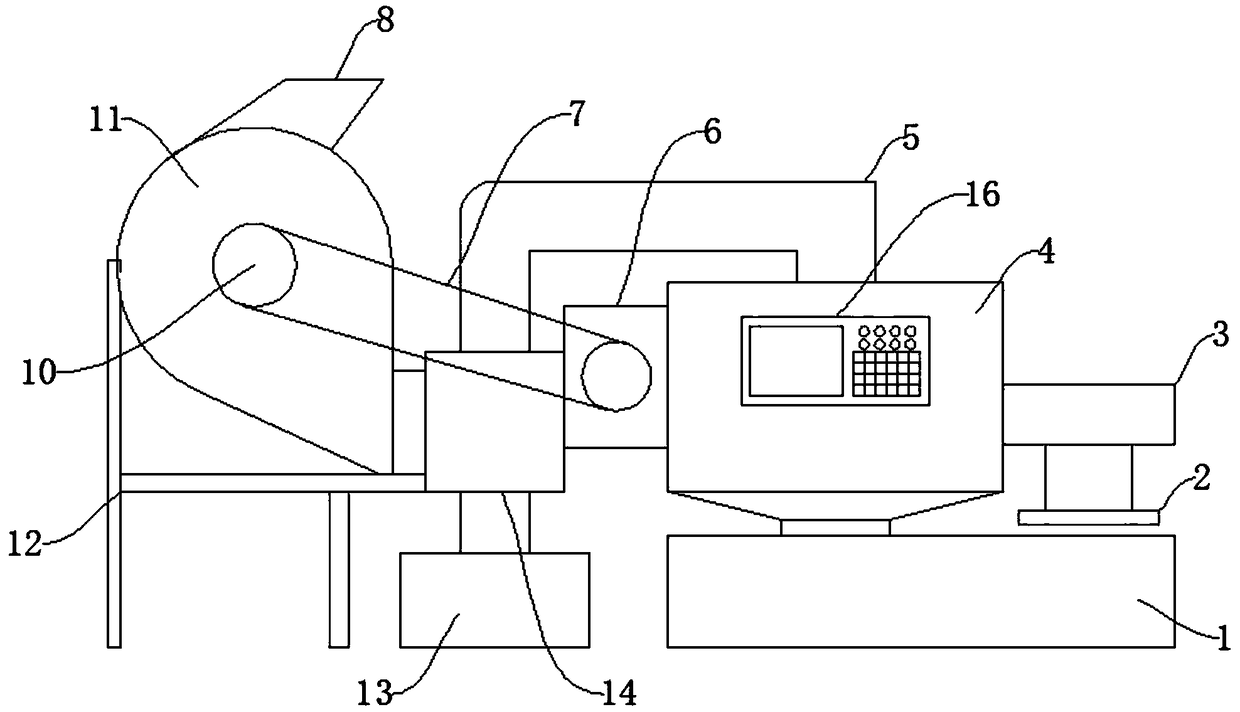

[0030] Such as Figure 1-Figure 4 As shown, a crushing and packaging device for garden cleaning includes a crusher box 11, a support frame 12 is arranged below the crusher box 11, a feed inlet 8 is arranged on the top of the crusher box 11, and a crushing wheel 9 is arranged inside the crusher box 11. 11 The front end is provided with a transmission wheel 10, the transmission wheel 10 is provided with a transmission belt 7, the other end of the crusher box 11 is provided with an air pump 14, a slag collection box 13 is provided below the air pump 14, a delivery pipe 5 is provided above the air pump 14, and a delivery pipe 5 is provided below A pulverizer box 4 is provided, and a pulverizer roller 15 is arranged inside the pulverizer box 4. A transmission module 6 is arranged on one side of the pulverizer box 4. A controller 16 is provided at the front end of the pulverizer box 4. The model of the controller 16 is KY02S, and the pulverizer box 4 is separately A hydraulic telesc...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is: in this embodiment, the conveying pipe 5 is connected to the pulverizer box 4 through a pipeline, the bottom of the pulverizer box 4 is a quadrangular pyramid structure, and two groups of pulverizing rollers 15 are arranged, and the pulverizing rollers 15 A crushing knife is arranged on the top.

[0033]Specifically, such setting helps the rubbish after being crushed for the first time to be concentrated into the collection module 1 through the discharge port at the bottom of the crushing machine box 4 after being crushed.

[0034] The working principle of the present invention is: when the device is used for cleaning, crushing and packaging garden waste, the controller 16 controls the device to work, and the waste falls into the crusher box 11 through the feed port 8, and the transmission module 6 drives the transmission wheel 10 to rotate, The transmission wheel 10 drives the transmission belt 7, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com