Supply machine for automatic disk change and splicing of tobacco sheets

A tobacco sheet and supply machine technology, which is applied in the directions of tobacco, application, thin material processing, etc., can solve the problems of reducing the filling amount of tobacco sheets in the final product, separating the head end of the difficult-to-new tobacco sheet, and reducing the strength of the extrusion part, etc. Stitching quality and reliable technical support, reliable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

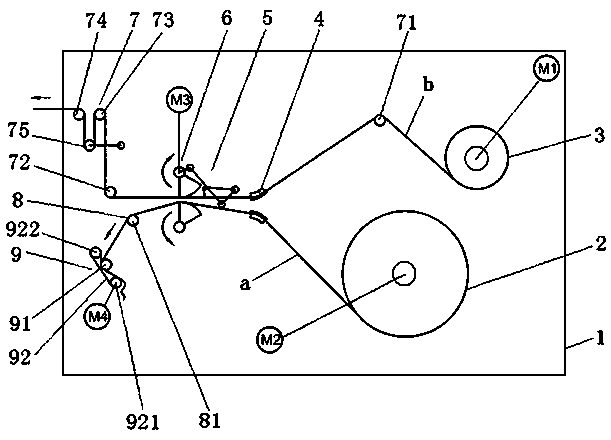

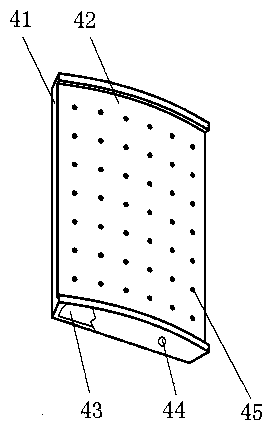

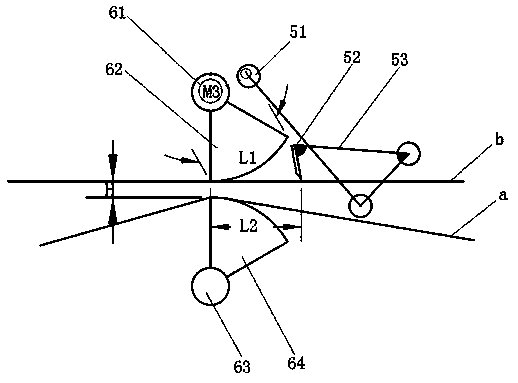

[0024] Such as Figure 1-Figure 6 The present invention provides a supply machine for automatic disc changing and splicing of tobacco sheets, comprising a frame 1, which is provided with a tobacco sheet disc clamping mechanism 2 for fixing and conveying new and old tobacco sheets a and b respectively 3. A splicing mechanism for splicing new and old tobacco sheets a and b. 6. Support wheel sets 7 and 8 for supporting new and old tobacco sheets a and b respectively. Used to cut off the new tobacco sheet a head end and The cutting mechanism 5,9 at the tail end of the old tobacco sheet b; wherein: the frame 1 is located in front of the splicing mechanism 6 and is respectively provided with a guide and limit mechanism 4 for limiting the positions of the new and old tobacco sheets a and b, and each guide and limit mechanism 4 includes a seat body 41 provided with a longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com