Sterilized milk preparation method

A technology of sterilized milk and raw milk, which is applied in the preparation of sterilized milk and the field of sterilized milk, can solve the problems of low denaturation rate of active nutrients, low physical and chemical changes, high storage temperature, etc., achieve low heat load intensity, reduce energy consumption, The effect of low heat treatment intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 A kind of preparation method of sterilized milk

[0023] Select raw milk that meets the national high-quality milk grade 1 standard, preheat it in a heat exchanger for 15 seconds and raise the temperature to 65°C, then immerse the preheated raw milk directly in a steam chamber at 160°C, and perform direct steam sterilization for 0.1s At this time, the temperature of the raw milk rises to 156°C, and then it is flash-cooled to 65°C within 5 seconds, aseptically homogenized, cooled until the temperature of the raw milk is lower than 25°C, and then aseptically filled.

Embodiment 2-9

[0024] The preparation method of embodiment 2-9 sterilized milk

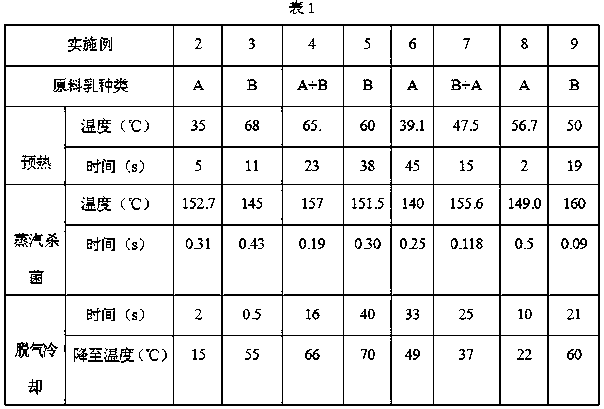

[0025] Examples 2-9 are respectively a method for preparing sterilized milk, which are carried out in the same order as in Example 1, and the difference lies in the type of raw milk, preheating temperature, preheating time, sterilizing temperature, and sterilizing time. , see Table 1 below for details:

[0026]

[0027] In the above table: A--fresh milk, B skimmed milk.

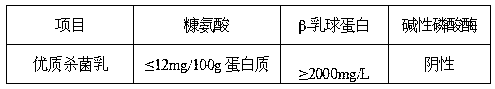

[0028] The milk products obtained by the preparation method of sterilized milk provided in Examples 1-9, after the actual test, the furosine value is <12mg / 100g protein, the β-lactoglobulin content is ≥2000mg / L, the shelf life is ≥30 days, and the temperature is 30°C Storage ≥ 10 days, the specific results are shown in Table 2 below:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com