Anodynia fish killing mechanism

A painless, cutting mechanism technology, applied in poultry/fish slaughtering/stunning, slaughtering, application, etc., which can solve problems such as incision offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

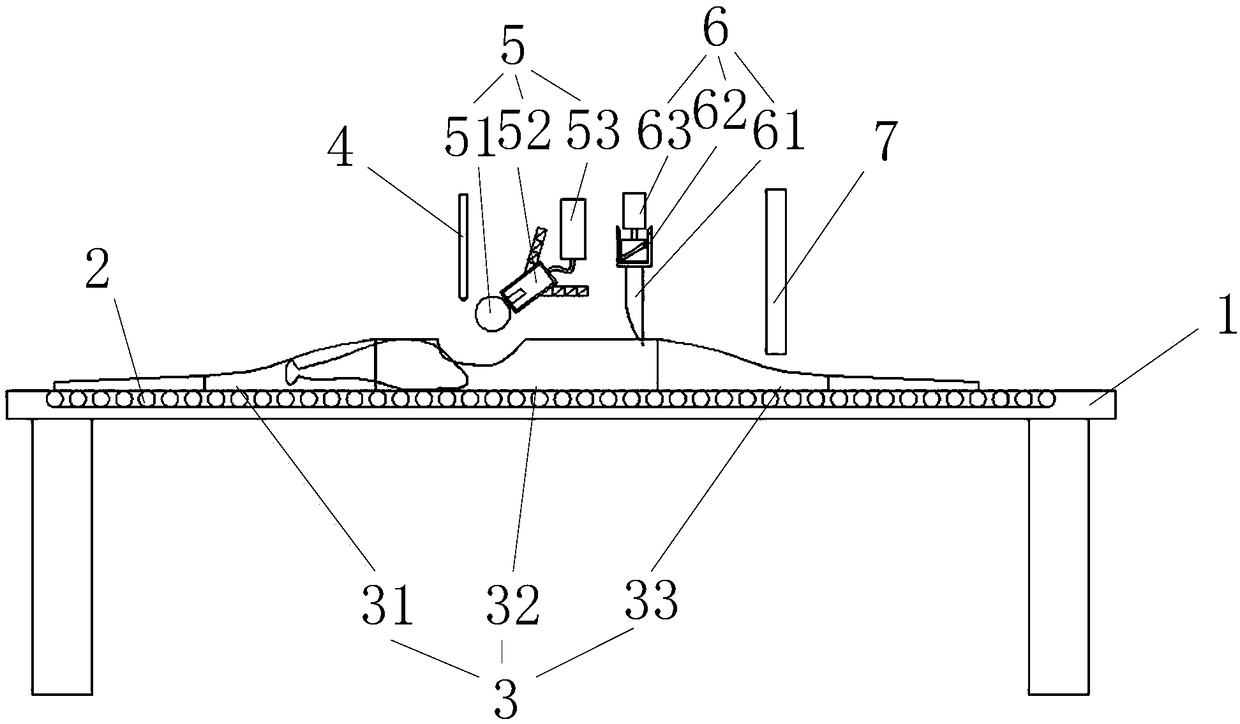

[0017] As the first embodiment of the present invention, a painless fish killing mechanism is proposed, such as figure 1 As shown, it includes: a working platform 1, a transmission track 2 is arranged on the working platform 1, and the transmission track 2 is a conveyor belt, and a concave-convex structure is arranged on the outer surface of the conveyor belt to increase the friction force. The side is provided with a righting baffle 3, and the righting baffle 3 is an arch bridge type, and the distance between the two righting baffles 3 in the middle section is smaller than the distance between the two righting baffles 3 at both ends, so that when the conveyor belt moves, Under the effect of uprighting baffle plate 3, fish changes from a flat state to a vertically standing state; uprighting baffle plate 3 includes a section 31, a processing section 32 and a separation section 33, and the processing section 32 is arranged between the section 31 and the section 31. Between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com